|

US$10,000.00-300,000.00

|

1 Set

(MOQ)

|

Basic Info.

Process Usage

Metal-Cutting CNC Machine Tools

Movement Method

Point to Point Control

Control Method

Open-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE, ISO 9001

Transport Package

Seaworthy

Production Capacity

500sets/Year

Packaging & Delivery

Package Size

2250.00cm * 2200.00cm * 2100.00cm

Package Gross Weight

1000.000kg

Product Description

BRIEF INTRODUCTION

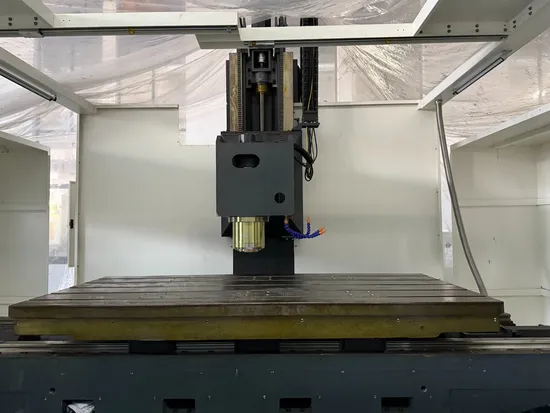

LM Double Columns CNC Machining Center

LM series double columns machining center has a compact structure, wide capacity of machining, good rigidity and vibration resistance. It can do milling, boring, drilling, tapping and other machinings. It is mainly suitable for the precision machining of concave and convex molds in the mold industry, complex cavities and surfaces. It is also suitable for precision machining of large and medium-sized parts in industries such as general machinery, automobiles, aerospace, instrumentation, and textile machinery.

Features of Zhongnan's double columns machining center: 1. LM series adopts high-rigidity gantry symmetrical structure, high cutting rigidity and stable running precision.

2. The beam adopts a stepped design structure to control the force and deformation within the effective range.

3. The Z-axis is equipped with a hard rail headstock as standard. The cabinet adopts high damping and high rigidity ductile iron structure, which can effectively suppress cutting vibration.

4. The whole series can be equipped with imported gearboxes, through hydraulic shifting, two-speed transmission, to achieve high torque output.

The whole machine adopts the gantry structure with moving table. The machine bed is fixed, Worktable moves in the X direction on the bed, the ram moves in the Z direction on the slide seat, and the slide seat and the ram move in the Y direction on the gantry beam. The X and Y axes adopt heavy-duty linear guideways, and the Z axis adopts plastic-coated flat guideway. The spindle box is placed at the lower end of the ram. The whole machine has feature of reasonable design, beautiful appearance and convenient operation.

Imported gearbox is optional to improve cutting efficiency.

XY axis with precision linear guideway, and Z axis with high rigidity flat guideway, which is suitable for heavy load and heavy duty cutting.

The Z-axis could be equipped with linear guideway which is suitable for high-precision machining.

Standard with Fanuc 0I MF control system. Mitsubishi, Siemens and other control systems are also available.

Parameters of Zhongnan's double columns gantry machining center LM8023

| Name | Unit | Model LM8023 |

| Worktable dimension(L×W) | mm | 8000×2000 |

| Max load of worktable | Tons | 29 |

| T groove (quantity×width×distance) | mm | 9×22×200 |

| X axis travel | mm | 8200 |

| Y axis travel | mm | 2300 |

| Z axis travel | mm | 1000 |

| Spindle end to worktable | mm | 200-1200 |

| Spindle center to column | mm | 2300 |

| Spindle type | | BT50 |

| Speed of spindle A | RPM | Belt:Max speed 6000(gear 1.5:1 optional) |

| Speed of spindle B | RPM | Z F gear box+belt Max 6000(two gears reduction 1:1;4:1) |

| Speed of spindle C | RPM | Gearbox drive: Max speed 6000RPM (two gears reduction 1:1;4:1) |

| Power of spindle | Kw | 15/18.5 |

| CNC system | | Fanuc 0i-MF/MITSUBISHI M80/SIEMENS |

| Rapid feed of X/Y/Z | mm/min | 6/12/10 |

| Capacity of magazine(ATC) | pieces | 24 |

| Positioning accuracy | mm | 0.04/0.02/0.016 |

| Repositioning accuracy | mm | 0.03/0.012/0.01 |

| Air supply | Kg/cm2 | 6 |

| Weight of machine | Tons | 55 |

| Dimension(L×W×H) | mm | 17500×5200×5000 |

Features:

1. Spindle

Adopt High-speed and high-precision spindle unit, which is designed with an air curtain protection function and equipped with cooling, temperature rise of the spindle is small, thermal deformation is small to get better machining accuracy.

2. Spindle

Equipped with 24 pieces drum magazine. The tool change response speed is fast, stable, safe and reliable. The tool can be changed nearby, shorten changing time.

3. Large span column

Large span column design with reinforcing ribs inside to increase rigidity of machine to increase stability of machining.

4. High Precision Ball Screws and Linear Guideways

Imported C3 grade ball screw and pre-tensioned backlash-free design to achieve high precision.

Imported P grade heavy load linear guideways are used to ensure no vibration during cutting and produce high-quality parts.

5. Standard with latest Fanuc control system, Siemens or Mitsubishi available as optional

Standard Configurations

| No. | Name | Quantity | Remark |

| 1 | Fanuc 0i MF | 1 | |

| 2 | Remote | 1 | |

| 3 | Air gun/water gun | 1 | |

| 4 | Automatic lubrication | 1 | |

| 5 | Spindle blowing device | 1 | |

| 6 | Air curtain | 1 | |

| 7 | Standard accessories | 1 set | |

| 8 | Documents | 1 set | |

| 9 | Gear box spindle | 1 | Optional |

| 10 | 24T drum magazine | 1 | Optional |

| 11 | Right angle milling head | 1 | Optional |

Company Profile

Nantong Zhongnan Intelligent Technology owns Zhongnan CNC technology, Zhongnan Intelligent, Xinsheng CNC technology and other subsidiaries such as foundry factory. Since its establishment in 2000, Zhongnan started with producing surface grinding machines, and gradually developed into high-end CNC machining center and manufacturing with production lines of CNC vertical machining center, high-precision gantry machining center, horizontal machining center, CNC vertical and horizontal milling machines, Zhongnan is one of the reputed manufacturers covers full production lines in the metal cutting machines industry in China. The products of the group company are widely used in defence industry, aerospace, automobile, green energy, mold and other fields of manufacturing.

Zhongnan Intelligent Technology has a production park covers 100,000 square meters. There are more than 380 employees, 30 senior engineers, and 20 R&D engineers. Production capacity covers the entire production chain of casting manufacturing, machining, painting, assembly, commissioning, inspection, etc.

100,000 square meters factory.

Factory Workship Show

Metal workshop 1 Metal workshop 1 Painting workshop

Assembly workshop 1 Assembly workshop 2 Machines ready in stock

Sheet metal workship 1 Sheet metal workship 1 Foundry plant

>>

Luxury nordic wooden legs plastic chair dining chairs leather dining room chairs DC125

>>

Hot Selling Worth Buying Enviromentally-friendly Embroidery Cotton Sewing Thread

>>

Round Cocktail Table LED Cocktail Table

>>

China Hand Operated Cultivator Tiller Rotavator Garden Tractor and Tiller for Sale

>>

Compact Shrink Wrap Machine for Space-Constrained Facilities

>>

Best Quality Canoe Single Sit on Top Fishing Kayak Pedal Drive 2.86m Pedal Kayak

>>

New 12cbm Hydraulic Cow Manure Collector Livestock Farm Cattle Cow Dung Cleaning

>>

Electric Garden Tools Plastic Blade Electric Power Cordless Mini Tiller Machine

>>

White Hose DN25 20 Meters, Without Coupling, En694certified.

>>

H Frame 6 Tiers Layer Chicken Cage for Poultry Farm

>>

FPT680 Farming Machinery Mini Rotary Cultivator FP170F Gasoline Engine Tiller

>>

Taijia ZC3-A Concrete Rebound Test Hammer with NDT Concrete Compressive Strength Testing Machine Measuring Range 10 to 60MPa

>>

14WG full copper 1.8m 6ft C19 Stripped 15cm PDU Style Power Extension Cable AC Power Cord Cable

>>

FRP GRP Above Ground Supply Liquid Water Pipe

>>

High Quality Carbon Iron Aluminum Metal Stainless Steel Cutting 1500W 2000W 3kw 6kw 12kw Fiber Laser Cutting Machine

>>

Exothermic Welding Mould Clamp

>>

Ready for Ship Lisami Stylish Women′s Footwear for Casual Outings and Special Events

>>

New Arrival Iran (Islamic Republic of) Andorra Granny Flat

>>

Warm and Environmentally Friendly Texture with Modacrylic / Viscose / Wool Blended Yarn 45/30/25

>>

Large Diameter Mining Rod Mill