Product Details

Product Description

Product Description

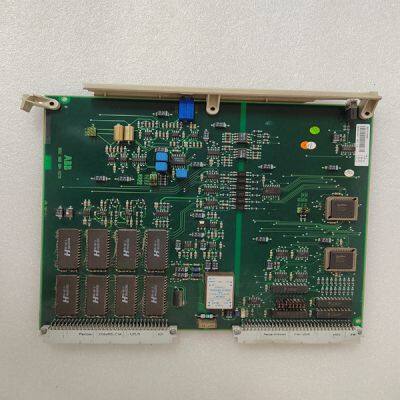

Brand: ABB

Type:DSDI146 3BSE007949R1

Origin: the Swiss

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts of our products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

The following remote auxiliary control indications are available through the Modbus links: Remote Aux is Enabled, Remote Aux is Active, Remote Aux is In Control, Remote Aux is Inhibited, and Remote Aux Input Failed Alarm. In addition to these indications, the Remote Aux Input Setpoint is also available. NOTE Relay indications can be programmed to indicate Remote Aux Control Active and Remote Aux Control Enabled status parameters. Remote / Speed Bias (RMT) Key Screens For this key to be active, the Remote Speed Setting, Synchronizing, or Load Sharing functions must be programmed. The Synchronizing and Load Sharing functions are configured by programming the respective function to an analog input. Figure 5-13 shows the possible screens that may appear if the RMT key is pressed. Only the screens related to the functions programmed will be displayed. Screens 3 and 4 appear when the Synchronizing analog input is programmed, screens 1 and 2 appear when Sync/Load Sharing analog input is programmed, and screens 5 and 6 appear when Remote Speed Setpoint input is programmed.

Remote Speed Setpoint The Speed PID setpoint can be remotely set by an analog input, if programmed. This Remote Speed Setpoint input can be enabled by pressing the front panel YES key from the Remote Speed Status screen (screen 6), closing the Remote Speed Setpoint Enable/ Disable contact (if programmed), or selecting Enable Remote Speed Setpt Control from either Modbus communications link (see Table 5-9). Remote Speed Setpoint input is disabled by pressing the front panel NO key from the Remote Speed Status screen (screen 6), opening the Remote Speed Control Enable/ Disable contact (if programmed), or selecting Disable Remote Speed Setpt Control from either Modbus communications link. MESSAGE 4 MEANING Disabled Remote is not selected Inhibited Remote is inhibited and cannot be enabled Enabled Remote is enabled but not in control of the Setpt Active Remote is in control of the Setpt but not in control of the actuator output In Control Remote is in control of the Setpt and in control of the actuator output Table 5-9. Remote Speed Messages The following Remote control indications are available through the Modbus links: Remote Speed Setpt is Enabled, Remote Speed Setpt is Active, Remote Speed Setpt is In Control, Remote Speed Setpt is Inhibited, and the Remote Speed Setpt Input Failed Alarm. In addition to these indications, Remote Speed Setpt Input analog value is also available. Relay indications can be programmed to indicate Remote Speed Setpt Active and Remote Speed Setpt Enabled status parameters. Synchronizing and/or Loadsharing The Synchronizing feature allows an analog input to bias the speed setpoint when using a DSLC for synchronization. The Synchronizing analog input is enabled by pressing the front panel YES key from the Sync Status screen (screen 4), closing the Sync Enable contact (if programmed), issuing an enable demand through an “F” key, or selecting Sync Enable from either Modbus communications link. The Synchronizing & Load Sharing feature allows an analog input to bias the speed setpoint when using a DSLC for synchronizing and load sharing. Load sharing is enabled automatically based on the generator and utility tie breaker status inputs. The Sync/Load Share input is enabled by pressing the front panel YES key from the Sync Status screen (screen 4), closing the Sync/Ld Share Enable contact (if programmed), issuing an enable command through an “F” key, or selecting Sync Enable from either Modbus communications link.

>>

High Quality Cosmos Aurora Lamp Sky Stereo Hifi Speaker galaxy projector light

>>

Single Phase Rail Type Multi Rate Electricity Meter

>>

Oblique Scupper Parapet Side Roof Drain with 2 Inch Push On Outlet

>>

Hot selling pecan nuts in shell for export to Thailand

>>

HC-B009 semi-auto Blood Testing Equipment semi automatic chemistry analyzer price

>>

FRP round shape cooling tower

>>

HC-S149 Infant head venipuncture training model/Neonate Scalp Venipuncture Simulator/Injection Nursing Training model

>>

Dropformer for Granulator Granulation Machine Dropformer for Granulating Machine

>>

Sodium Hydrosulphide 70%Min Yellow Flakes (NaHS)

>>

Automatic food biscuit production line Shortbread biscuit forming machine Peach crisp biscuit machine

>>

Stuffing mixer, meat mixer, food mixer

>>

White Cardboard Craft Take Away Packaging Folding Box Takeaway Disposable Kraft Paper Food Container for Soup and Rice

>>

10 Ton Container Loading Mobile Dock Ramp for Warehouse

>>

Sea surface search scanning radar ship AIS integrated photoelectric turntable linkage all-in-one machine sea search radar

>>

Canned Products Cage Loading and Unloading System Linked with Retort

>>

China Factory A4 Printer Paper Reams Making Machine Automatic Price

>>

Diesel Concrete Mixer with Delivery Pump

>>

Fanuc and CE 3 Axis CNC Drilling and Milling Router for Mold (ZJA10-1008)

>>

Wear Resistant Mixing Blade Mixing Arms Mixing Liners

>>

Bh-914-610 Arch Sheet Metal Roofing Roll Forming Machine