US$12,299.00

11-49 Pieces

Basic Info.

Application

Home Appliance, Environmental Equipment, Petroleum Machinery Manufacturing, Agriculture Machinery, Textile Machinery, Food Machinery, Aerospace Industry, Automotive Industry, Shoemaking Industry, Woodwork Industry, Advertising Industry, Aerospace

Cooling System

Water Cooling

Technical Class

Continuous Wave Laser

Applicable Material

Metal

Structure Type

Gantry Type

Laser Classification

Solid Laser

Laser Technology

Laser Control Fault Cutting

Appearance Material

Metal Shell Material

Energy Consumption Level

Low

Transport Package

Wrapping Film and Plastic Soft Bag, Wooden Box

Specification

4500*2300*1800

Production Capacity

5000pieces/Year

Packaging & Delivery

Package Size

4550.00cm * 2300.00cm * 2100.00cm

Package Gross Weight

1800.000kg

Product Description

Product Description

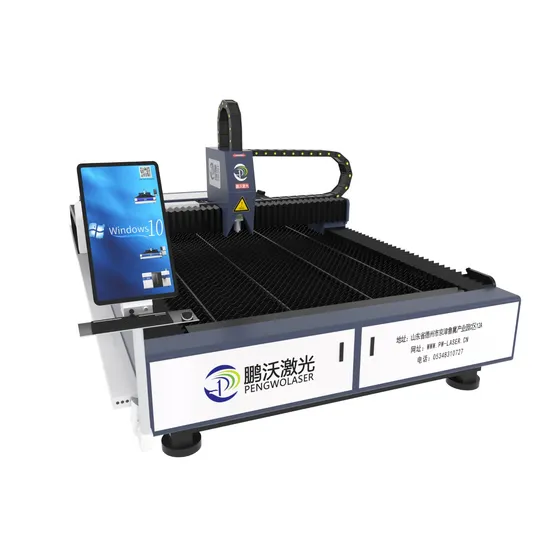

1. Built with an indomitable and steadfast frame, the Versatile 3015 Laser Cutter Machine stands as a testament to superior engineering. Crafted with meticulous self-welding techniques, it undergoes rigorous high-temperature annealing and stress-relief processes to assure unparalleled stability, effectively eradicating any potential deformation risk.

2. Featuring a premium imported and originally packaged fiber laser, our machine guarantees exceptional beam quality. It ensures precise, efficient metal cutting across a wide array of applications, positioning it as an industry frontrunner.

3. Designed with exactitude, this machine seamlessly integrates top-tier imported high-precision ball screw drive, rack and pinion drive systems, and high-precision linear guides. This ensures that every cut is executed with remarkable accuracy and unwavering dependability.

3. Our cutting-edge machine merges elite imported guide drive components with advanced servo motors, delivering outstanding precision and rapid operations. This enhances its performance to consistently deliver extraordinary results.

4. Equipped with an advanced automatic lubrication device, our machine also boasts a comprehensive dust removal and fume exhaust system within the cutting area, promoting smooth operations and ease of maintenance, ensuring flawless functionality.

5. Experience the ease of a high-precision CNC operating system, empowering you to seamlessly design and perform immediate cutting of diverse text and graphics, achieving all creative and operational objectives with exceptional efficiency.

6. Leading in energy-efficient technology, this machine is engineered to use minimal power while adhering to energy-saving and eco-friendly principles, leading the charge towards a more sustainable and eco-conscious future.

Detailed Photos

Raytools or BOCI laser head

Discover the epitome of excellence with our world-class brand, celebrated globally for its exceptional quality. This laser head is distinguished by its state-of-the-art built-in dual water cooling system, engineered to meticulously maintain the ideal temperatures for both collimation and focusing elements. This remarkable feature not only adeptly prevents lens overheating but also dramatically extends their lifespan. Additionally, the protective lens is masterfully crafted to shield vital components, ensuring sustained longevity and consistently reliable performance.

RAYCUS/MAX laser source

RAYCUS and MAX epitomize the zenith of laser source manufacturing in China. Renowned for their extraordinary high photoelectric conversion rates and unmatched precision in processing, these laser sources are synonymous with exceptional quality, enduring lifespans, and unparalleled product performance. Their esteemed reputation transcends domestic confines, captivating the international market with their groundbreaking technology and steadfast reliability.

Control system

Our sophisticated intelligent operating system is meticulously engineered to precisely regulate laser power, frequency, cutting speed, and other critical parameters, thereby ensuring unwavering stability and uniformity throughout the cutting process. Paired with an intuitive human-machine interface, this system significantly reduces the skill threshold for operators, ushering in seamless and highly efficient operations.

High-rigidity machine bed

Experience unmatched precision with our machine bed, expertly 'tempered' at high temperatures to meticulously eliminate internal stress within the welding zones. This process not only effectively prevents deformation but also significantly enhances the bed's toughness. Consequently, every cut is executed with impeccable accuracy and superior quality, tailored to meet an extensive array of diverse cutting requirements from our esteemed clientele.

Water Chiller

Our water chiller is equipped with a cutting-edge advanced cooling system, featuring key components sourced from globally acclaimed brands. This ensures a profound reduction in the temperature of laser equipment, facilitating smooth and uninterrupted operation. As a result, it substantially enhances production efficiency, guaranteeing that your equipment functions at optimal levels under all conditions.

Product Parameters

| Name&Model | Laser Cutting Machine G1530F-A/G1540F-A |

| Working Area | 1500mm*3000mm/1500mm*4000mm |

| Machine Structure | Stable & strong welded bed with high temperature annealing |

| Beam | Aviation aluminum/Integrated cast aluminum beam |

| Moving Speed | 120m/min |

| X axis travel (mm) | 1530 |

| Y axis travel (mm) | 3050/4050 |

| Z axis travel (mm) | 80 |

| Max acceleration | 0.8G |

| Position Accuracy | ±0.03mm |

| Repositioning Accuracy | ±0.02mm |

| Computer | Industry Computer |

| Transfer method | Gear rack dual drive |

| Working Voltage | 380V,3phase,50hz/60hz(customized) |

| Dimension | 4500*2300*1800/5500*2300*1800 |

Certifications

Company Profile

Shandong Pengwo Laser Technology Co., Ltd. stands proudly as a beacon of innovation and expertise from the vibrant epicenter of Dezhou City, Shandong Province. Since our establishment in 2005, we have distinguished ourselves as renowned specialists in the field of laser processing equipment. With an unwavering commitment to pioneering advancements and superior quality, we have emerged as leaders, offering cutting-edge laser processing intelligent manufacturing solutions. Driven by our unwavering commitment to excellence and strategic expansion, we have ascended to the forefront as a premier domestic provider of comprehensive laser application equipment solutions. Our expansive operations include two state-of-the-art production facilities located in the Tianquxin District and Pingyuan County, encompassing over 80,000 square meters. Here, the latest technology fuses seamlessly with unmatched craftsmanship.

At the core of our esteemed product lineup is an array of sophisticated middle and high-power laser cutting equipment. This is complemented by our expertly engineered laser welding equipment, laser cladding equipment, and an extensive variety of other high-precision laser processing machinery. Each product is meticulously crafted to meet the diverse needs of our clients, ensuring outstanding performance and unmatched reliability in every application.

After Sales Service

Installation Training Options (Choose from 3):

A. Unleash the full potential of your investment with our comprehensive installation and operational training resources. Immerse yourself in meticulously crafted, intuitive videos and easy-to-understand manuals available in English. Should you face any installation, operational, or adjustment challenges, our expert technical team is on standby, ready to assist via multiple communication channels, including email, fax, phone, and instant messaging platforms such as Messenger and WhatsApp.

B. Enhance your skills by embarking on an unforgettable journey to China for a fully immersive training experience. Your comfort is our priority, ensuring a seamless learning journey, complete with accommodation to enrich your stay and enhance your learning experience.

C. Leverage the expertise of our dedicated Chinese after-sales service team, featuring proficient English-speaking engineers prepared to resolve any challenges you face. To add to your convenience, we can also assist in arranging your flights to ensure a hassle-free experience.

Recommended Training Duration: 3-7 working days.

For those desiring on-site installation, commissioning, and comprehensive training-which includes maintenance and machine operation-right at your location, these valuable services are generously provided free of charge by the supplier. However, it is expected that the customer will cover associated costs, such as the supplier's airfare, meals, accommodation, local transport, translation services, internet, communication, and visa fees at the buyer's location, based on the actual expenses incurred.

Exhibition

FAQ

Q1. When was your factory established?

We have been specialized in the R&D, manufacturing and intelligent manufacturing solutions of laser processing equipment since 2005, mainly focusing on laser processing equipment such as fiber laser cutting, laser welding equipment, laser cladding equipment, etc.

Q2. What should I do if there is a problem with this machine during the warranty period?

The quality assurance period is 12 months from the date the goods arrive at the destination port. Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period. After the quality assurance period, if you need to repair or replace parts, you must pay.

Q3. How to install and use?

We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the machine. When you encounter installation, use or adjustment problems, we will provide technical guidance by email, fax, telephone/Messenger/WhatsApp, etc.

Q4. What should I do if there is an after-sales problem?

You can directly describe your problem to the after-sales staff. China's strong after-sales service team. Our engineers (employees) can communicate and solve problems in English, and can be arranged once a day per person when you need it. If I need to go to your place to help, I will quickly arrange to go there and quickly fly to help you.

Q5. How about wholesale price?

If you are a wholesaler, distributor or agent, please contact us to get wholesale price.

>>

Therapy Apparatus Equipment Whole Body Check-up Equipment Use For Professional medical examination Center

>>

Professional Factory of Laptop Charger for DELL Power Adapter 90W 19.5V 4.62A

>>

Auto Shock Absorber for Honda CRV

>>

Industrial Robot Arm Made in China for Automated Punch

>>

Water Proof Network cable Lan cable Cat5e UTP Ftp cat5E Cat6

>>

Hot Sale Outdoor Children Quick-Dry Breathable Non-Slip Water Sports Beach Shoes for Children

>>

Wholesale Sweetheart Sleeveless Lace-Up Side Split Beaded Chiffon Wedding Dresses SQS036

>>

Golden Cup Paper Cup Making Machine Manufacturers for Hot and Cold Drinking Cups Coffee Tea Cup Making Machine

>>

Motorcycle Clutch Disc Plate Spare Parts for Ex5

>>

Customized Semi Automatic Burr Free Pipe Tube Circular Saw Metal Cutting Machines

>>

EMERSON SE3008 KJ2005X1-MQ2 13P0072X082

>>

canned pineapple fruit cocktail production line machine factory plant

>>

CE EPA Mini Digger 1000kg Bagger Mini Excavator 1 Ton Mini Excavator Prices Low Than SD for Sale with Attachment

>>

Car SUV and Trucks Quick Connect Plug Jumper Cables 1 Gauge 30 Feet 800A Booster Cables Heavy Duty Automotive Booster Jumper Cables with UL-Listed Clamps

>>

Plastic Paint Bucket Oil Tanks Making Moulding Injection Molding Machine

>>

iPad Tabletop Metal Bracket (new)

>>

13.5V 0 Bar 140L/H high pressure tractor engine diesel generator fuel pump 4132A018 for Perkinstractors

>>

CNC Machine Tool Ck61100 Large Aperture, High Precision and Strong Load-Bearing

>>

Laboratory fungal incubator

>>

Customised stainless steel connecting fittings