Product Details

Product Description

Product Description

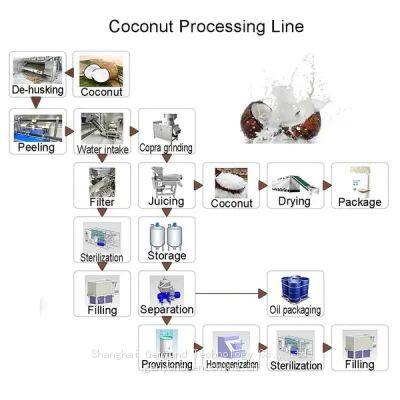

Coconut water coconut milk production line

Suitable for all kinds of coconut to produce coconut water, coconut milk, juice with coconut ,coconut powder and etc. This processing line is combined with peeler, pulverizer, screw separator, filtration, disc centrifugal separator, blending system, degasser, homogenizer, sterilizer, filler, flusher, autoclave, ink coder and etc. With advanced design philosophy, high degree of automation; Main equipments are all made of high quality food grade stainless steel, accords with the hygienic requirements of food processing.

* Produce coconut water, coconut milk, coconut juice and etc

* Capacity ranges from 500kg/h to 20t/h,designed by the customer's needs

* Configuration is flexible, according the requirement of client to prepare the suitable machine

* With aseptic filler and hot filler

* Modular design, which can combine different processing technique

* High automatic degree, labor-saving

* Equipped with CIP to make clean easy

* Material contacted with production is SUS304 stainless steel, fully meets the food hygiene safety requirements

Description

Coconut water coconut milk production line

End Products and Package of Coconut Processing Line

--Concentrate Coconut water filled into aseptic bags(5kg,220kg or 1000kg)

--Single strength coconut water(Non-concentrated coconut water)filled into tin cans,bottles or asptic bags.

--Coconut milk/cream filled into aseptic bags,tin cans or bottles.

--Desiccated Coconut filled into poly bags,jars or pouches.

--Virgin Coconut Oil(VCO)filled into bottles or barrels.

Single Strength Coconut water is a refreshing and cooling drink. Its sodium and potassium content makes it an ideal drink for rehydration. In a healthy, undamaged coconut, the water is even sterile. Fresh coconut after dehusking and deshelling, then use one needle to pierce one hole on the coconut to extract coconut water. After extraction, coconut water is filtered. Filtration can be done using a double cloth filter. This is especially important for mature coconut water, as dry husk fibres and dirt from the shell of mature nuts can easily get into the coconut water during extraction. After filtration, the coconut water is quickly cooled to retard any deterioration reactions. Then, it is sent for separation, homogenizing, degassing, subsequent pasteurization and aseptic packaging.

If coconut water is extracted at a location away from the aseptic packaging site, the filtered coconut water can be packed into food grade plastic bags, quickly cooled and transported to downstream processing. The single strength coconut water content is 92%-95% and soluble solids is about 12 brix.

Concentrated coconut water: Concentrated coconut water is about 60-65 brix and water content is about 35%-40%. Fresh coconut water after extracting, filtering, cooled to 10 ℃ and storing into double layers insulation tanks. Then the low-temperature coconut water will be prepasteurization and separation. Then, it goes into a multiple-effect evaporation stage to increase °Brix levels. Usually, the product is concentrated to 60-65 °Brix and packed into 200 kg plastic bags in drums for bulk transportation under ambient conditions. It is recommended that the concentrate coconut water will be stored at below zero temperature for 2 years.

Coconut milk/cream:Coconut milk and cream are produced from 10-13 months old mature coconuts when the kernel is hard and thick. They are natural oil-in-water emulsions extracted from the mature coconut kernel. The difference between coconut milk and cream is the amount of fat. The fat content of the coconut milk is 5%-20%, whereas coconut cream reaches to 20%-50%. To extract coconut milk for industrial manufacturing purposes, mature coconuts go through deshelling and paring. Pieces of kernels are then sent into industrial-scale cutters and grinders. Next, grated coconut kernel then goes into a series of screw extractors to extract coconut milk. The residual kernel from this first press is then mixed with water before it is pressed again to increase extraction yield. After extraction, coconut milk is filtered to remove large contaminants. It can then be standardized to a pre-determined level of fat and blended with other ingredients. Finally, coconut milk is homogenized, degassed, pasteurized and aseptically filled into aseptic bags or small package like bottles or tin cans.

Coconut oil: Coconut oil is one of the main products traditionally derived from the coconut kernel. Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process. While the method that uses fresh coconuts as starting material is generally called the fresh-wet or fresh-dry process. Based on different separation methods, coconut oil can be classified into two types – RBD coconut oil and virgin coconut oil (VCO). The former is refined, bleached and deodorized (RBD) from dry extraction, while the latter is produced by fresh-wet and fresh-dry extractions.

Key Machine of Coconut Water and Milk Processing Line:

Coconut water extracting machine

It is composed of a coconut water drilling machine and a coconut water extraction conveyor,the machine is made of SUS304 material and with vat for coconut water collection.It is semi-automatic,one operator holds the coconut and aims the coconut eye to the drill to get the water then pours coconut water into the conut water collection vat.

Coconut dehucking machine

Coconut dehusking machine is to remove the outer hard huck.This type of peeling machine is semi-automatic equipment.It is mainly composed of a round cutter plate,a hard alloy cutter head,a wedge blade knife and a geared motor.When the machine is working,manually hold the coconut,align the position of the front coconut eye with the sprout blade,and press it down.At this time,the rotating peeling blade and the wedge-shaped top blade squeeze the coconut placed in it,thus smoothly peeling the coconut meat.The whole machine is designed for fixed installation and height-adjustable placement,which can satisfy both large-scale production line use and individual independent use,and has a wide range of adaptability.The capacity is 200-300PCS/H.

Company Profile

Shanghai Genyond Technology Co., Ltd.

Shanghai Genyond Technology Co., Ltd. is a manufacturer of extracting unit and fruit & vegetable processing line with well-equipped testing facilities and strong technical force.With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in food and beverage and other industries.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

View more

>>

Farm manure dewatering machine pig/cow /duck manure dry wet separator solid liquid extrusion separator

>>

Factory Price 18inch Wall Fan 90W Plastic Grils Electric Fan Electric Fan/ Industrial Fan/ Wall Fan

>>

2021 popular vela machine for sale / vela smooth equipment price

>>

Whole House Customization Furniture for Hotel Home

>>

W/R Fresh Frozen Hardtail Scad Fish

>>

Simple Satin Plunging V Neckline Ball Gown Long Sleeves Wedding Gowns

>>

Factory supply directly mining crusher powder making hammer crusher

>>

Sustainable Agricultural Machinery for Efficient Composting and Fertilizer Creation

>>

LED Night Light with Qi Wireless Charger Cellphone Power Bank Socket RGB Night Light

>>

14000 Gauss Ss Magnetic Bar/Rod Magnet Bar for Iron Removing/Ceramic/Plastics/Water Treatment

>>

3 PCS test hoses 8 PCS test points 3 PCS pressure gauges hydraulic pressure gauge test kit for Excavator

>>

Module AFP0RE32T DVP16SN11TS A1SJ71AT21B Module Q68DAV VW3A3608 DVP32XP11R AFP04123 AFP2402

>>

Solar Charging Station for Passenger and Freight Electric Tricycle Tuk Tuk

>>

Gear Pump 705-21-43010 705-51-30190 705-52-40160 Gear Pump 07429-71203 07429-71203 07441-67503 705-58-44050

>>

Laboratory Cellulose Dry Spray Wet Spinning Machine

>>

Hot Sales Cosmetic Facial Mask Brush Body Face Paraffin Wax Treatment Brush Makeup Tool Salon Beauty Tool

>>

coffee vending machine

>>

Innovative Design Features for Custom High-Performance LPG Cylinder Production

>>

Factory Wholesale High Efficiency Sweet Corn Picker and Silage Harvester Machine

>>

Flexible Oil and Weather Resistant Rubber Tube Hydraulic Hose