| | parameters | Specifications |

| 1 | Effective width of core paper | 1300mm-2600mm |

| 2 | roll diameter) | φ1400mm |

| 3 | Core paper weight | 80g/M²-150g/M²(Medium to high strength corrugated paper) |

| 4 | Adhesive | Starch glue,PVA |

| 5 | Finished paper core thickness | 5-60mm |

| 6 | Honeycomb paper core cross-cut production speed | 1100cuts/min(Thickness6mm,paper core weight90-120g) |

| 7 | Honeycomb hole side length | To be determined |

| 8 | Honeycomb flatness | ±0.1mm |

| 9 | Heating method | Steam heating |

| 10 | Equipment installed power | Approximately50KW |

| 11 | normal production power consumption | 50KW*50%-60% |

| 12 | Total weight of equipment | Approximately80T |

| 13 | Equipment dimensions | 35300mm length×5600mm width×3800mm high |

| 14 | Equipment operation direction | To be determined |

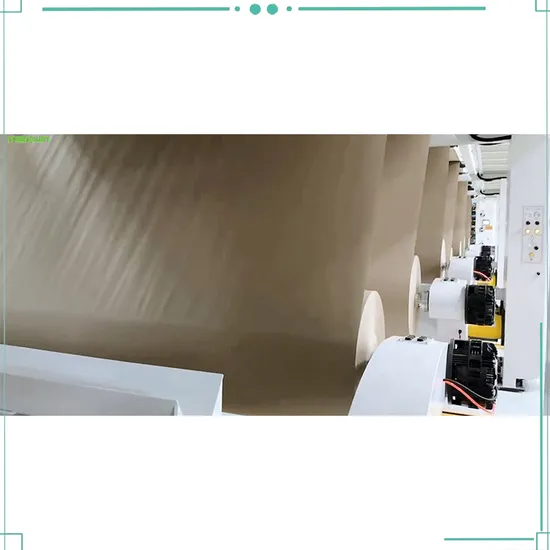

Main technical parameters of the equipment: Discover the meticulously designed technical features of our High Efficiency Cardboard Laminating Machine for Honeycomb Sheets. Engineered for superior performance, this machine boasts advanced specifications that guarantee high-speed operation, precise laminating accuracy, and minimal maintenance needs. Experience the excellence of modern engineering tailored for your industrial demands.

| 2600 paper core machine project configuration table |

| | part name | project | Remark |

| 1 | Core paper unwinding unit | Hydraulic Shaftless Paper Holder

(with simple paper changing Components) | |

| 2 | aisle on the platform | Rack Transition Parts | |

| 3 | Core paper gluing unit | Core paper gluing parts ( can be equipped with double- toothed rollers) | |

| 4 | Core paper composite drying unit | Single group ( can be equipped with double pressure rollers) composite traction parts , equipped with 2 groups of composite drying | |

| 5 | Cross cutting machine unit | High-speed cross-cutting machine parts | |

| 6 | Paper core automatic collection unit | Finished paper core automatic collection part | |

| 7 | heating method | steam heating | |

| 8 | Main control component brand | Mitsubishi, Inovance, Lenze | |