|

US$500.00-50,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Model NO.

pet pelletizing granulating machine

Computerized

Non-Computerized

Name

Bags Pelletizing Machine

Handle

Waste Plastic Film

Core Part

Plastic Film Extruder

Drying

Centrifuge Dewatering

Clean Medicament

Cuastic Soda

Machine Material

Stainless Steel 304

Temperature Control

Omron

Frictiong Washer

High Speed Type

Transport Package

Film Sea Packing

Production Capacity

10 Sets Per Year

Product Description

Recycling PP/PE/PC/Pet Flakes Plastic Granule Making Machine Price

Description of Recyled PE PP plastic film pelletizing machine:

PE PP plastic pelletizing machine with international advanced recycling technology and combined with the actual application condition. This plastic pelletizing recycling machine is design specializes for recycling the washed plastic PE film, such as PE plastic bags, plastic packing films, plastic shopping bags, agricultural film etc.

After PE PP plastic pelletizing machine processing, the final products are plastic pellets/granules, which can be to produce plastic bags, drainage pipes, plastic board/sheet etc.

The whole Recyled PE PP plastic film pelletizing machine line includes(customizable):

Belt conveyor → Compression barrel (agglomerator) → Efficient extruder → Non-stop hydraulic screen filter changer → Water ring cutting → Vibration machine → Dewatering machine → Blower → Storage hopper. Electric control panel

Photos of the main parts in Recyled PE PP plastic film pelletizing machine:

Belt conveyor of Recyled PE PP Plastic Film Pelletizing Machine

Compector/ agglomerator of Recyled PE PP Plastic Film Pelletizing Machine

Extruder for the Recyled PE PP Plastic Film Pelletizing Machine

Non stop screen changer unit of Recyled PE PP Plastic Film Pelletizing Machine

Watering cooling die face cutting unit of Recyled PE PP Plastic Film Pelletizing Machine

Vibriation machine of Recyled PE PP Plastic Film Pelletizing Machine

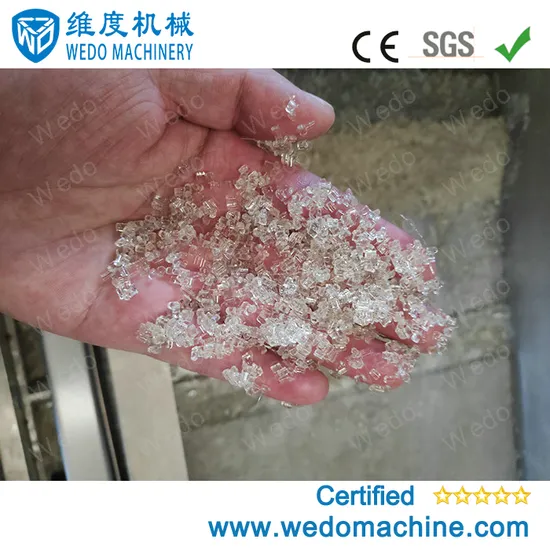

The pellets get from Recyled PE PP Plastic Film Pelletizing Machine

Function of the main parts in Recyled PE PP plastic film pelletizing machine:

1. Belt conveyor feeding: as standard design, plastic scraps such as film, bag, filament, raffia conveyed into the compacting barrel through belt conveyor; to process rolls' scraps, roll hauling off device is an optional feeding method. Motor drives of conveyor belt and hauling device cooperate with ABB inverter. Feeding speed of conveyor belt and roll hauling off is fully automatic based on compactor's barrel' space. Metal detector can combined with belt conveyor, and can interlock with control system, to warn and stop the system, in case that metal into the screw.

2. Compression barrel: crushing and compacting the material, the rotatory blades of compactor will cut up incoming scraps. Frictional heating which caused by high-speed rotatory blades will heat the scraps, and let them shrinking just below their agglomerating point. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material, which enables a fast and stable feeding from the compactor directly into the extruder.

3. Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

4. Non-stop hydraulic screen filter changer: double stage filtering, fore filtering in the first extruder, and fine filtering in the second extruder, to reduce the frequency of filtering sieves changing. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

5. Cutting pelletizing: die-face water ring pelletizing system as the standard granulating method in Wedo system. Self-adjusting pelletizing head for the best granulate quality, and consistently correct blades pressure can ensure long running. Rotate speed of cutting blades is automatic based on melt extruding pressure. Advanced dewatering vibration sieve combining with vertical-type centrifugal dewatering present high performance dried pellets.

Parameters of Recyled PE PP plastic film pelletizing machine:

CAPACITY

(kg/h) | POWER CONSUMPTION

(kw) | WATER CONSUMPTION | LABOUR | HUMIDITY CONTENT |

| 100-150 | 150 | Keep water cool | 1-2 | <2% |

| 200-300 | 200 | Keep water cool | 1-2 | <2% |

| 300-400 | 280 | Keep water cool | 1-2 | <2% |

| 450-500 | 350 | Keep water cool | 1-2 | <2% |

| 700-800 | 460 | Keep water cool | 1-2 | <2% |

Advantage of Recyled PE PP plastic film pelletizing machine:

Very low labor request.

Stable running.

Automatic constant temperature control.

CE certification, ISO9001 certification, SGS certification

Configuration based on client requirement and material, and give reasonable suggest.

Wedo Produce steps: Wedo have a fully step for the Recyled PE PP Plastic Film Pelletizing Machine producing before packing and shipping, this ensure the plastic recycling machine will delivery in good quality, and custerm will get good machine. Wedo service: We do best service for you in Recyled PE PP Plastic Film Pelletizing Machine Any further about the Recycling PP/PE/PC/Pet Flakes Plastic Granule Making Machine Price, please contact us timely we will give your professional fully support.

>>

All Weather Garden Leisure Outdoor Chairs for Home Waterproof Woven Dining Room Wicker Rattan Garden Chair

>>

Cheese Slicer With Adjustable Thickness - Heavy Duty Stainless Steel Cheese Slicers With Wire - Premium Wire Cheese Slicer

>>

Ladies softshall jacket winter jacket windproof jacket 2017

>>

Universal Single Ku Band LNB

>>

4 Cavities Semiautomatic Blow Moulding Machine/Blow Moulding Machine/Plastic Injection Molding Machine/SGS Pet Preform Machine /Water Machine/Plastic Machinery

>>

HD lace front wig

>>

CI871K01 3BSE056797R1 ABB Communication module logic Manager

>>

Best Choice for Mattress and Furniture Soft Comfortable Needle Punched Non-Woven Fabric for Sale

>>

WiFi6 Speed Test and Maintenance Tool for Operators

>>

Garlic Peeling Machine Split Production Line

>>

Non Abrasive and Chemical Residue Free Fiber Optic Pulse Portable Air-Cooled Laser Cleaning Machine, Rust Removal Cleaning Machine Price

>>

china yarn for gloves nm10/1 recycled yarn dyed cotton yarn raw white

>>

24-58meters Construction Machinery HOWO Brand Concrete Pump Truck for Sale

>>

High Efficiency VSD Rotary Screw Air Compressor

>>

China Laser Cutting Machine 1000W 2000W Price/CNC Fiber Laser Cutter Sheet Metal Stainless Steel Laser Cutting Machine

>>

China Top Hot Selling Custom-Made Automatic Rubber Silicone Hydraulic Compression Vulcanizing Machine

>>

High Precision 5-Axis CNC Vertical Machining Center for Sale

>>

Sdhj6 Single Shaft Paddle Type Poultry Feed Livestock Feed Mixing Machine

>>

LANYING 4ft 5ft 6ft 7ft 8ft 9ft 10ft wire mesh weaving machines

>>

IS200TSVCH1AJE