Basic Info.

Product Type

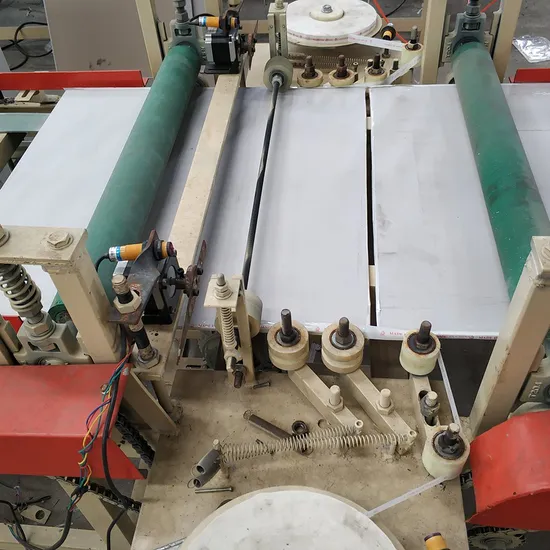

Gypsum Ceiling Board Machine

Automatic Grade

Automatic

Application

Making Gypsum Ceiling Board

Gypsum Ceiling Board Size

595*595mm,600*600mm,603*603mm,1200*600mm

Gypsum Ceiling Board Thickness

7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm

Automation Degree

Different Automatic Degree Available

Control System

PLC Simens

Screw Diameter (mm)

65 mm

Plastic Processed

PE, PP, PVC, WPC

Third Party Inspection

Accept

Core Components

Motor, Pump

Applicable Industries

Building Material Shops, Manufacturing Plant

Screw Speed (Rpm)

150 Rpm

Transport Package

Sea Transportation Packing

Specification

Standard or Customized

Production Capacity

100sets/Year

Packaging & Delivery

Package Size

300.00cm * 200.00cm * 100.00cm

Package Gross Weight

100.000kg

Product Description

Product Description

The market prospect of gypsum Ceiling board equipment

Since Epidemic happen, the shipping market is becoming crazy, and the delivery cost to some countries are raising prices dramatically, especially in the Middle East, Europe, North America, and South America. The cost of shipping price is even higher than the cost of a full container of gypsum board & gypsum ceiling.

In the current situation, China's Gypsum ceiling product exports have been seriously affected, and even unable to export at all, to be honest, We have not had such a situation in this industry for more than ten years. So now more and more old customers are re-purchasing this machine from us to enlarge the capacity to occupy more market share in their own country's gypsum industry.

For this production line, we provide clients with are one-stop service, we will dispatch engineers to install and commission the machine and also will train workers on how to produce qualified gypsum ceilings. Besides, accessories and raw material (like PVC film, glue, etc. )procurement services will be provided all year round.

Product Parameters

Main Parameters

Capacity

2~3million sqm/300 days(basis of calculation:L:595mm,T:7mm,W:595mm,weight: 5.5kg/8-10hrs/shift )

Finished Board Specification

Length×width:595×595mm,600×600mm,603×603mm,1200×600mm

Thickness:7.0mm, 7.5mm, 8.0mm,8.5mm 9.0mm

Ceiling board size 603*603mm ,need big board size :1220*2440mm;

Ceiling board size 595*595mm, need big board size 1200*2400mm;

Ceiling board size 600*600mm, need big board size 1210*2420mm :

Request for The Raw Material

Name

| Specification

| Package

| Kg /package

| 20'container

loading quantity

| Remark

|

PVC Film

| width :1.230m

one roll =600m

| Roll

| 57kg

| 86340sqm/70200m/

117rolls /6670kg

|

|

Aluminum Foil

| length:1.230m

One roll

=125kgs=10000m

| Roll

| 125

| 180rolls/1800000m/

23000kg

| 1 kg could stick

about 100sqm

gypsum board

|

Glue for PVC

| 50kgs/barrel

| Barrel

| 50kg

| 410barrels/20500kg

| 1kg could stick

35~40sqm

|

Glue for Aluminum

| 50kgs/barrel

| Barrel

| 50kgs

| 410barrels/20500kg

| 1kg could stick

58~64sqm

|

Remark:The above information is just for your reference.

The Place And Workshop Requirements

PVC lamination production line, building area of 1000 square meters

Worker's Arrangement

Working days per year:300days

Shift:1 shift

Working hours per shift:8 hours/shift

Equipment Each Part Introduction :

Personnel Allocation:

System

| Workers needed

|

Forklift Operator

| 1worker/shift

|

Machine Operating

| 3workers/shift

|

Packing System

| 3 worker/1shift

|

Monitor

| 1 worker/1shift

|

Total

| 8workers/shift

|

Main Equipment Introduction

Equipment Advantages

1.Technology: The gypsum PVC ceiling machine we designed has a national invention patent, and it's a high degree of automation.

2.Perfect design system: We can design and improve the scheme according to the customer's site and other situations,and make the machinery completely conform to the user's needs.

3.Production process: Our workers from the engineers to general production personnel all have rich experience in machinery design and manufacturing.

4.Machine Connection and Testing with Raw Material Before loading

If the customer wants to install the equipment by himself, most important is some detailed work should be done well before delivery of the machine from China

First, each machine part needs to be debugged, then all the machines are connected together to debug, and finally, the raw materials are put on the machine to debug the machine.

If there is an inappropriate place, we will be resolved it immediately.

Without debugging in our Workshop, the client is very difficult to install and run the machine himself.

Company Profile

Customer Visit China and Abroad project

Since the Epidemic happen, it is very difficult for customers to visit China, we welcome customers o visit our projects abroad, also we could show customers our projects through the online show.

With our strength and experience, we could help customers complete gypsum projects quickly.

We master the most advanced technology which could help customers get qualified products and occupy more markets soon.

We have been deeply engaged in the field since 1990, setting up 100+gypsum projects domestic and abroad, covering more than 20 countries in the world, and also there are projects cases that can be visited in each Area. Besides we developed online visiting which breaks the limit of the virus.

After Sales Service

Installation &commissioning service

Before engineers arrive, we will provide the following documents to let the client prepare in advance

1-Installation tools list

2-Installation workers list

3-Installation Estimated Schedule list

After the machine arrived at the client's factory.

We will send engineers to install and test the whole production line. Also, our engineers will provide training for your workers, teach them how to produce good quality finished products.

After installation is finished, we will provide the following service to assist the client run the factory smoothly

1-Responsibilities and assignment statement

2-Maintainance manual

3-Raw material and spare part list

Professional sale service

Our philosophy We are not only selling the machine.

What we focus on is customers' demands, keep innovation, keep updating, and meeting &surpass customers' requirements.

What we provide is not ONLY the machine BUT the whole system.

Rich Experience

*Experience in gypsum technology research since 1994. *Experience in 100+ projects manufacture & install abroad and domestic.

Professional Team

*Experts provide professional design for the project. * Experienced installation group gets projects into production quickly.

*The whole group provides a powerful One-stop sourcing service

Full Range of Services

*Pre-Sales: full cooperation with pre-preparation work. * In-Sales: on-time reporting of production progress.

*After-Sales: Lifetime & 24h technical support.

Irreplaceable Advantages

*Case projects visiting abroad on-site & online. *Training to workers & engineers.

* Spare part and raw material supply.

Company Introduction

What we provide is not ONLY the machine BUT the whole system Our company is Yurui(SHANDONG) Machinery, we are a group company with 8 branches for different building materials and machinery since 1990.

Yurui is mainly engaged in providing one-station services for gypsum series projects.

With our strength and experience, we could help customers complete gypsum projects quickly. We master the most advanced technology which could help customers get qualified products and occupy more markets soon.

Raw Material for Gypsum Series Production Line

We are only providing solutions for machines but also provide one-stop procurement services for gypsum raw materials, like gypsum board covering paper, modified starch, water reducer, white latex, PVC film, and aluminum foil, etc.

>>

Dr. Bang Automatic CNC Fabric Cloth Leather Textile Cutting Machine

>>

Mini Metal Drill Press Machine Z4120g Z4125g Z4132g

>>

DSDP160 57160001-KG ABB module supply

>>

Lock Female Connection Stainless Steel Sleeve Metal Sleeve

>>

Custom Logo Men′s Winter Puffer Vest Plus Size Quilted Warm Sleeveless Hooded Jacket Solid Winter Coat Cotton Vest

>>

Customized Logo Printed Football #5 PVC Soccer Ball & Football for Promotion

>>

Mini humidifying air conditioning fan 02

>>

Raptor style body kits conversion front bumper upgrade body kits for ford ranger 2015+ T7/T8

>>

Mini USB Female Connector of 10 Pin

>>

IC693ALG221 IC693ACC323B | GE FANUC MODULE PLC DCS In Stock

>>

350W Convenient Medical Device Portable Endoscope LED Xenon Cold Light Source for Endoscopy

>>

Thermo Tank Split Solar Water Heater Guangzhou Solar Powered Portable Heater

>>

400 Ton Rubber Molding Machine, Large Workbench, Rubber Foot Mat Molding Machine, Automotive Rubber Parts Hydraulic Press

>>

Factory Supply Toner Cartridge for Konica Minolta Accuriopress C2060 C2070 C3070 C3080 Bizhub Press C1060 C1070 Toner Tn619 Tn-619 2060 3060 3080 1060 Tohita

>>

double roller oat flaking mill

>>

Digital Thermometer and Hygrometer for Accurate Indoor Climate Control

>>

Bamboo cooking utensil set engraved, kitchen spatula set burn Wholesale

>>

2 in 1 Metal USB 3.0 Flash Drive High Speed Portable Mobile Phone USB Drive for Print Logo

>>

Automatic Spiral PVC Coil Forming Machine Plastic Coil Making Machine

>>

Motorcycle Mirror Camera 7/8" Handle Bar End Side Rear-View Rear Rearview Mirrors Cafe Racer 3" Round Motorcycle Mirror