|

US$11.00-21.00

|

1,000 kg

(MOQ)

|

Basic Info.

Technique

Var Melting+Machining

Grade

Gr1,Gr2,Gr3,Gr4,Gr5,Gr9,Gr23

Material

Ta6V Titanium Alloy

Surface Treatment

Machining

Standard

ASTM, ISO, AMS, JIS, DIN

Diameter (mm)

380, 480, 580, 620, 720

Weight(T)

1t, 1.5t, 2.5t, 5t

Transport Package

Wood Case

Production Capacity

200tons/Year

Product Description

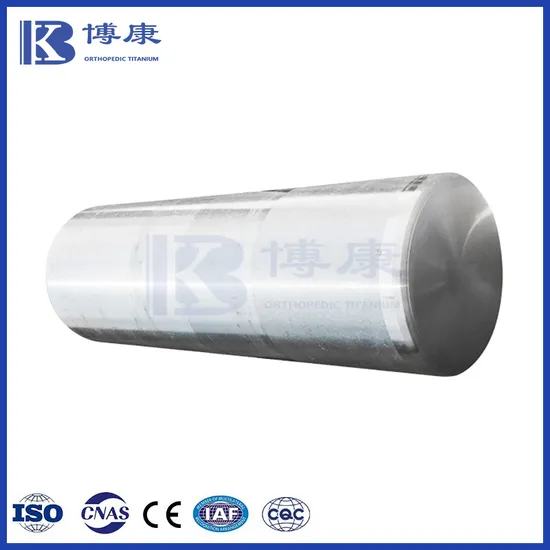

Product Description Titanium Ingot (Ti Ingot) Description:

Our titanium ingots are made from high-purity sponge titanium and premium intermediate alloys. After precise mixing and pressing, they are welded using advanced vacuum electron beam welding to prevent the introduction of impurities. The ingots then undergo three rounds of VAR (Vacuum Arc Remelting) to increase purity and reduce impurity elements, resulting in uniformly composed titanium ingots. Common specifications include 380, 480, 580, and 620. Titanium Ingot offers a robust and reliable solution for various industrial applications.

Titanium Ingot (Ti Ingot) Specifications

Product Name

| Titanium Ingots

|

Material Grade

| Gr1,Gr2,Gr2H,Gr3,Gr4,Gr5,Gr7, Gr9,Gr11,Gr12,Gr16,Gr23,Gr29, Ti-6Al-2Sn-4Zr-2Mo, Ti-5Al-5V-5Mo-3Cr,etc

|

Diameter (mm)

| Φ380, 480, 580, 620, 720

|

Weight(T)

| 1T,1.5T,2.5T, 2.5T, 5T

|

Standard

| ASTM B977;ASTM F67;ASTM F136; ISO5832-2;ISO5832-3;AMS4928;AMS4965;AMS4967;ASTM B348; ASTM B863

|

Melting times

| Triple

|

High-quality titanium ingots with various diameters, tolerances and performances can be customized according to requirements

Impurities Content:

| Grade | Element Impurities, not more than(%) |

| Fe | C | N | H | O |

| Gr1,Gr2,Gr3,Gr4 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 |

| Ti-6Al-4V Eli | 0.25 | 0.08 | 0.03 | 0.012 | 0.13 |

Titanium Ingot Features:State-of-the-art VAR (Vacuum Arc Remelt) furnacesBlending expertise - consistent melts Melting with tighter tolerances than standards requireCustom chemistries within grades availableCompetitive lead times

Titanium Ingot Production Process:

Sponge Titanium→Compacting Electrodes→Electrode Welding→Triple VAR Melting→Packaging→Delivery

Applications of Titanium Ingot

Titanium ingots are the raw material for forgings, rings, tubes, and profiles.

1. Medical: Titanium Ingot is also used in a wide range of medical applications. Due to its biocompatibility and corrosion resistance, Titanium Ingot is often used in the manufacture of medical devices such as scalpels, operating tables, and artificial joints. It is also used in areas such as dentistry and orthopedics.

2. Aerospace: Titanium Ingot has a wide range of applications in the aerospace sector. It is used to manufacture aircraft components such as fuselages, wings, and engine parts. Due to its lightweight and high-strength properties, Titanium Ingot helps to reduce the weight of aircraft, improve fuel efficiency, and ensure flight safety.

3. Automotive manufacturing: Titanium Ingot is also widely used in automotive manufacturing. It is used to manufacture automotive components such as engine parts, exhaust systems, suspension systems, etc. These components need to withstand high temperatures and corrosion. These parts need to withstand high temperatures and corrosion, and Titanium Ingot's resistance to corrosion and high temperatures makes it an ideal material choice.

4. Chemical industry: In the chemical industry, Titanium Ingot is widely used in the manufacture of equipment such as chemical reactors, heat exchangers, and pipes. Due to its corrosion resistance and high-temperature tolerance, Titanium Ingot can withstand the corrosion of various chemicals and high-temperature environments to ensure the long-term stable operation of chemical equipment.

Chemical Composition Chemical Composition

ASTM B977 Chemical Requirements:

| Grade | UNS NO. | C

max | O

range or max | N

max | H

max | Fe

range or max | Al | V | Pd | Ru | Ni | Mo | Cr | Co | Zr | Nb | Sn | Si | Other Elements,max,each | Other Elements,max,total |

| 1 | R50250 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 2 | R50400 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 3 | R50550 | 0.08 | 0.35 | 0.05 | 0.003 | 0.30 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 4 | R50700 | 0.08 | 0.40 | 0.05 | 0.003 | 0.50 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 5 | R50400 | 0.08 | 0.20 | 0.05 | 0.003 | 0.40 | 5.5-6.75 | 3.5-4.5 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 6 | R54520 | 0.08 | 0.20 | 0.03 | 0.003 | 0.50 | 4.0-6.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 2.0-3.0 | ... | 0.1 | 0.4 |

| 7 | R52400 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.12-0.25 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 9 | R56320 | 0.08 | 0.15 | 0.03 | 0.003 | 0.25 | 2.5-3.5 | 2.0-3.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 11 | R52250 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | 0.12-0.25 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 12 | R53400 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | ... | ... | 0.6-0.9 | 0.2-0.4 | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 13 | R53413 | 0.08 | 0.10 | 0.03 | 0.003 | 0.20 | ... | ... | ... | 0.04-0.06 | 0.4-0.6 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 14 | R53414 | 0.08 | 0.15 | 0.03 | 0.003 | 0.30 | ... | ... | ... | 0.04-0.06 | 0.4-0.6 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 15 | R53415 | 0.08 | 0.25 | 0.05 | 0.003 | 0.30 | ... | ... | ... | 0.04-0.06 | 0.4-0.6 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 16 | R52402 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 17 | R52252 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 18 | R56322 | 0.08 | 0.15 | 0.03 | 0.003 | 0.25 | 2.5-3.5 | 2.0-3.0 | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 19 | R58640 | 0.08 | 0.12 | 0.03 | 0.003 | 0.30 | 3.0-4.0 | 7.5-8.5 | ... | ... | ... | 3.5-4.5 | 5.5-6.5 | ... | 3.5-4.5 | ... | ... | ... | 0.15 | 0.4 |

| 20 | R58645 | 0.08 | 0.12 | 0.03 | 0.003 | 0.30 | 3.0-4.0 | 7.5-8.5 | 0.04-0.08 | ... | ... | 3.5-4.5 | 5.5-6.5 | ... | 3.5-4.5 | ... | ... | ... | 0.15 | 0.4 |

| 21 | R58210 | 0.08 | 0.17 | 0.03 | 0.003 | 0.40 | 2.5-3.5 | ... | ... | ... | ... | 14.0-16.0 | ... | ... | ... | 2.2-3.2 | ... | 0.15-0.25 | 0.1 | 0.4 |

| 23 | R56407 | 0.08 | 0.13 | 0.03 | 0.003 | 0.25 | 5.5-6.5 | 3.5-4.5 | | | | | | | | | | | 0.1 | 0.4 |

| 24 | R56405 | 0.08 | 0.20 | 0.03 | 0.003 | 0.40 | 5.5-6.75 | 3.5-4.5 | 0.04-0.08 | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 25 | R56403 | 0.08 | 0.20 | 0.03 | 0.003 | 0.40 | 5.5-6.75 | 3.5-4.5 | 0.04-0.08 | ... | 0.3-0.8 | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 26 | R56404 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 27 | R52254 | 0.08 | 0.18 | 0.03 | 0.003 | 0.20 | ... | ... | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 28 | R56323 | 0.08 | 0.15 | 0.03 | 0.003 | 0.25 | 2.5-3.5 | 2.0-3.0 | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 29 | R56404 | 0.08 | 0.13 | 0.03 | 0.003 | 0.25 | 5.5-6.5 | 3.5-4.5 | ... | 0.08-0.14 | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 30 | R53530 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | 0.20-0.80 | ... | ... | ... | ... | 0.1 | 0.4 |

| 31 | R53532 | 0.08 | 0.35 | 0.05 | 0.003 | 0.30 | ... | ... | 0.04-0.08 | ... | ... | ... | ... | 0.20-0.80 | ... | ... | ... | ... | 0.1 | 0.4 |

| 32 | R55111 | 0.08 | 0.11 | 0.03 | 0.003 | 0.25 | 4.5-5.5 | 0.6-1.4 | ... | ... | ... | 0.6-1.2 | ... | 0.6-1.4 | ... | ... | 0.6-1.4 | 0.06-0.14 | 0.1 | 0.4 |

| 33 | R53442 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | ... | ... | 0.01-0.02 | 0.02-0.04 | 0.35-0.55 | ... | 0.1-0.2 | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 34 | R53445 | 0.08 | 0.35 | 0.05 | 0.003 | 0.30 | ... | ... | 0.01-0.02 | 0.02-0.04 | 0.35-0.55 | ... | 0.1-0.2 | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 35 | R56340 | 0.08 | 0.25 | 0.05 | 0.003 | 0.20-0.80 | 4.0-5.0 | 1.1-2.1 | ... | ... | ... | 1.5-2.5 | ... | ... | ... | ... | ... | 0.20-0.40 | 0.1 | 0.4 |

| 36 | R58450 | 0.08 | 0.16 | 0.03 | 0.001 | 0.03 | ... | ... | ... | ... | ... | ... | ... | ... | 42.0-47.0 | ... | ... | ... | 0.1 | 0.4 |

| 37 | R52815 | 0.08 | 0.25 | 0.03 | 0.003 | 0.30 | 1.0-2.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 38 | R54250 | 0.08 | 0.20-0.30 | 0.03 | 0.003 | 1.2-1.8 | 3.5-4.5 | 2.0-3.0 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.1 | 0.4 |

| 39 | R53390 | 0.08 | 0.15 | 0.03 | 0.015 | 0.15-0.40 | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | ... | 0.30-0.50 | 0.1 | 0.4 |

| 42 | R53475 | 0.08 | 0.25 | 0.05 | 0.003 | 0.30 | ... | ... | ... | ... | 0.1-1.0 | 3.0-4.5 | ... | 0.1-1.5 | ... | ... | ... | 0-0.50 | 0.1 | 0.4 |

Analysis Tolerances

ASTM B977 Analysis Tolerances:

| Element | Product Analysis Limits, max or Range, % | Permissible Variation in Product Analysis |

| Aluminum | 0.5 to 2.5 | ±0.20 |

| Aluminum | 2.5 to 6.75 | ±0.40 |

| Carbon | 0.1 | ±0.02 |

| Chromium | 0.1 to 0.2 | ±0.02 |

| Chromium | 5.5 to 6.5 | ±0.30 |

| Cobalt | 0.2 to 0.8 | ±0.05 |

| Hydrogen | 0.02 | ±0.002 |

| Iron | 0.80 | ±0.15 |

| Iron | 1.20 to 1.8 | ±0.20 |

| Molybdenum | 0.20 to 0.4 | ±0.03 |

| Molybdenum | 0.60 to 1.2 | ±0.15 |

| Molybdenum | 1.50 to 4.5 | ±0.20 |

| Molybdenum | 14.0 to 16.0 | ±0.50 |

| Nickel | 0.3 to 0.9 | ±0.05 |

| Niobium | 2.2 to 3.2 | ±0.15 |

| Niobium | >30 | ±0.50 |

| Nitrogen | 0.05 | ±0.02 |

| Oxygen | 0.30 | ±0.03 |

| Oxygen | 0.31 to 0.40 | ±0.04 |

| Palladium | 0.01 to 0.02 | ±0.002 |

| Palladium | 0.04 to 0.08 | ±0.005 |

| Palladium | 0.12 to 0.25 | ±0.02 |

| Ruthenium | 0.02 to 0.04 | ±0.005 |

| Ruthenium | 0.04 to 0.06 | ±0.005 |

| Ruthenium | 0.08 to 0.14 | ±0.01 |

| Silicon | 0.06 to 0.40 | ±0.02 |

| Tin | 0.62 to 3.0 | ±0.15 |

| Vanadium | 0.6 to 4.5 | ±0.15 |

| Vanadium | 7.5 to 8.5 | ±0.40 |

| Zirconium | 0.6 to 1.4 | ±0.15 |

| Zirconium | 3.5 to 4.5 | ±0.20 |

| Residuals (each) | 0.15 | 0.02 |

Titanium Ingots Tolerances:

| Diameter (mm) | ≤350 | >350~550 | >550~720 | >720~820 | >820~1040 | >1040 |

| Tolerance | +5

-30 | +5

-40 | +5

-60 | +5

-70 | +5

-80 | +5

-100 |

Product Category

| | |

| Titanium Bar/Rod | Titanium Wire | Titanium Disc |

| | |

| Titanium Ingot | Nitinol/Nickel Titanium | Artificial Joint Castings |

Certifications

About Bokang

Our Advantages

FAQ Q: Are you a direct manufacturer or trading company?

A: We're a manufacturer with more than 18 years of professional production experience.

Q: Do you offer free samples?

A: Usually, our sample is free but we need our customer to pay the freight.

Q: What is the minimum quantity per order?

A: 1 kg. For regular standard medical and aerospace materials, based on our production capacity of 20 tons per month for titanium wire and rods. the stock inventory could meet all your requirements.

Q: What products can you offer?

A: We specialize in the production of pure titanium, titanium alloy, titanium rods, wires, discs, nitinol alloy, etc.,

Q: What's the payment term?

A: When we quote for you, we will confirm with you the way of transaction, FOB, CIF, CNF, etc.

For mass-production goods, you need to pay 30% deposit before producing and 70% balance against a copy of documents. The common way is by T/T. L/C is also acceptable.

Q: What applications do your products relate to?

A: Our titanium alloys and nitinol alloys are widely used in medical, aerospace, and other Industries.

Q: How can we get your price?

A: We need the below information to quote for you:

1). Product Name

2). Standard

3). Material Grade (Chemical Composition)

4). Dimension

5). Quantity

Q: Can you do customized products?

A: Yes, we support customized products according to the customers' drawings or samples.

Q: How do you guarantee the quality of your goods?

A: We ensure quality by inspecting every process and using advanced testing equipment to conduct comprehensive checks, ensuring finished products meet customer and international standards.

Q: How do you deliver the goods to us?

A: We will usually ship the goods by sea and air according to your requirements.

>>

10kw off Grid Solar Energy System Complete Solar Panel Power System for Home Industrial Use

>>

New Full-Automatic Paper Element Oil Air Filter Full Auto Knife Pleating Machine

>>

Low Price Custom Dyeing Heavy Silk Fabric 135cm Width Mulberry Silk Viscose Spandex Charmeuse Natural Fabric for Women Luxury Garment

>>

China Factory Yn Qsz 2400 Silage Corn Combine Harvester

>>

35CrMo square steel tube seamless profile pipes cold drawn round tubes professional manufacturer

>>

12 Bamboo bread tong/bamboo wooden kitchen tongs,bamboo toaster tongs

>>

Food Sanitary Stainless Steel Electric Jacketed Kettle with Agitator

>>

XTIOT XT2003C 2D Codes Scanner Module Barcode QR Code Reader With LED Indicator Small Size Easy To Integrate

>>

Professional Manufacturing Agricultural Machinery Rotary Tiller with High Quality

>>

High Quality Cone Crusher for Gold Ore Aggregate Concrete Granite Mining Crushing

>>

High Temperature Epdm Rubber Air Intake Suction Hose 96328721

>>

15.6inch Light and Ultra-Slim 11th N5095 Laptop with High Memory 16GB+1tb 128GB Educational Business Notebook OEM Cheap Netbook

>>

Electronic Tensile Universal Testing Machine up to 5000N

>>

Mobile Phone Car Pillow Holder Tablet Stand Back Seat Headrest Mount Bracket

>>

Diamond PCD CNC High Gloss Profile Cutter Diamond Dresser

>>

New Type Knitting Machine Spare Parts Yarn Feeder Usage Thread Clamp Holder

>>

Byloo New design gym dumbells on sale cast iron adjustable dumbbell set gym men

>>

Stainless Steel Service Housing Box Fabrication Bending Parts Sheet Metal Enclosure Part

>>

Full Servo up-Acting CNC Bending Machine with Stable Performance Low Noise Energy Conservation and Environment Protection

>>

Air Freight Air Shipping Air Cargo From China