Basic Info.

Processing Object

Cereals

Processing Technics

Crushing-before-Mixing

Screen Mesh

With Screen Mesh

Grinding Equipment Type

Feed Hammer Mill

Pellet Mill Type

Ring Die Pelleter

Bulking Machine Type

Single Screw Bulking Machine

Expanding Method

Wet Expansion

Applicable Materials Shape

Powder

Model

Szlh250,Szlh320,Szlh350,Szlh400,Szlh420,Szlh508

Feed Pellets

Chicken, Cattle,Fish,Pet...

Capacity

1t/H, 2-5t/H, 5-8t/H, 8-10t/H,10-15t/H, 15-20t/H

Service

Installation, Testing, Training

Transport Package

Wooden Box

Specification

SZLH series

Production Capacity

2sets/Month

Packaging & Delivery

Package Size

250.00cm * 220.00cm * 180.00cm

Package Gross Weight

1500.000kg

Product Description

Product Description

Our factory is a professional manufacturer specialized in designing, making high quality feed pellet mill and building turn key feed pellet production line. With 20 years' experience, professional technical R&D team.

We had built 1-30t/h feed pellet mill lines(chicken feed pellet lines, cattle feed pellet lines,poultry pellet lines and so on) in: Russia, Romania, Thailand, Malaysia, Ukraine, Iraq, Algeria and so on.

Feature of feed pellet machine, feed pellet mill

1.This feed pellet machine is equipped with screw feeder controlled by FC inverter with permanent magnet to removing iron impurities.

2. Stainless steel conditioner makes even retention and sufficient cooking effect.

3. Gear directly-connecting driving is adopted for high accuracy and efficiency. The output can increase 20% comparing to feed pellet machine driven by belts.

4. High quality bearings(NSK),motor( Siemens or China top brand-Wannan ) is adopted to makes operation smoothly.

5. Main gear and pinion shaft adopt the carbonizing quenching with high accuracy, to ensure smooth driving, low noise and long service life.

6. The ring die& roller assemblies are quickly assembled and disassembled.

7. Applicable for all kinds of high grade animal/livestock/aqua feed. Sinlge, double or three layers of conditioner is optional.

8. Speed-adjust feeding, adopted by this feed pellet machine, can control the feeding capacity correctly to fit for different and meet the production requirement of pellets with different diameters.

Product Parameters

Technical parameters of feed pellet machine, feed pellet mill

| Model | Main power (kw) | Capacity (t/h) | Feeder power (kw) | Conditioner power (kw) | Die diameter (mm) | Feed pellet size (mm) |

| SZLH250 | 15 | 0.5-1 | 0.55 | 2.2 | 250 | 2-18 |

| SZLH320 | 37 | 2-5 | 0.75 | 2.2 | 320 | 2-18 |

| SZLH350 | 55 | 2-7 | 0.75 | 3 | 350 | 2-18 |

| SZLH420 | 90/110 | 3-14 | 1.5 | 5.5 | 420 | 2-18 |

| SZLH508 | 110/132/160 | 4-20 | 1.5 | 7.5 | 508 | 2-18 |

Related machine

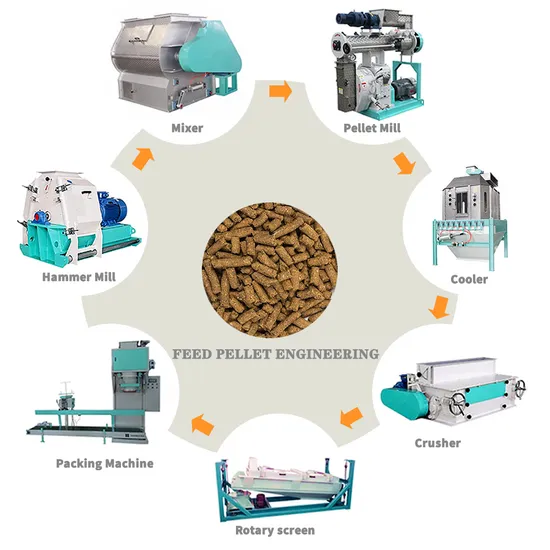

Total process for feed pellet mill line, poultry feed production line

Raw material receiving →Grinding →Mixing →Pelletizing →Cooling & Sifting →Packing

Detailed processes of feed pellet mill line, poultry feed production line

1. Raw materials receiving Process:

Raw materials can be corn, rice bran, soybean, grain, wheat, soybean meal / cake and etc. Precleaner can remove the impurities in raw materials.

2. Grinding Process:

The feed grinder can grind the raw material ingredients to the required size. There are various hammer mills which can satisfy different requirements.

3. Mixing Process:

Mixing is considered to be one of the essential operations in feed pellet processing. Lack of proper mixing may lead to reduced diet uniformity, affecting the feed pellet quality.

4. Pelletizing Process:

Feed pellet mill is the core equipment of the whole production line. According to different raw material, material formula and working condition, we can offer you different pellet mills.

5. Cooling Process:

The feed pellets pressed out by the feed pellet mill are hot and moist. They can't be crushed, screened or packed immediately. Counter-flow feed pellet cooler is designed to cool or dry the feed pellets. It can decrease the temperature and moisture of the feed pellets, preparing for the following processes.

6. Crushing Process:

Different poultry, livestock or aquatic feed pellets are with different sizes. Some big ones should be crushed into small ones. Roll type feed pellet crumbler is just the equipment for feed pellet crushing. Double-roll feed pellet crumbler is suitable for crushing poultry feed, such as chicken feed, duck feed and goose feed etc. Three-roll feed pellet crumbler is suitable to crush aquatic feed including fish feed and shrimp feed etc.

7. Screening, Grading and Packing Process:

The rotary grading sieve can be used to screen and grade the feed pellets. After processing, you can get the qualified feed pellets without fine powder.

Packing Process

The feed pellets should be packed for transporting, storing or selling.

8. Automatic PLC Control System(Customized):

With the automatic PLC control system, the production line is with high efficiency and convenient operation

Detailed Photos

Company Profile

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2009,sell to Domestic Market(16.00%),Oceania(12.00%),South Asia(10.00%),Eastern Asia(10.00%),North America(9.00%),Northern Europe(9.00%),Central America(8.00%),Southeast Asia(7.00%),Eastern Europe(6.00%),Africa(5.00%),Western Europe(3.00%),South America(2.00%),Southern Europe(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Biomass fuel pellet production line,Livestock&poultry feed production line,pellet machine,wood pellet mill,drum dryer

4. why should you buy from us not from other suppliers?

Moren than 20 experiences of design,manufacturer the pellet mill, complete pellet production line and the spareparts with over 5 professional engineers for design and 5 teams for guiding installation

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese

Quality First And Everytime Good Quality!

Any demands, please kindly contact with me:

Carrie Huang(Sales manager)

>>

800L Agricultural Four Wheel Drive Self Propelled Boom Sprayer Used for Farmland

>>

USB Cable Plug Connector Injection Making Machine / Plastic Injection Moulding Machine

>>

wholesale clear phone case transparent TPU Phone case phone cover case for iPhone14/14 Pro Max

>>

High Alumina Textile Ceramic Guide V Guide

>>

311101m500-Ds Fuel Pump Module Assembly for KIA Cerato Forte (08~13)

>>

Greetmed Hot sale 1000ml 1500ml travel medical vomit emesis bag

>>

Automatic die-cast product nitrogen deflashing machine Ultra Shot NS-180C

>>

Agricultural Machinery Floating Fish Feed Pellet Extruder Aquaculture Fish Food Farm Equipments

>>

sieve shaker vibrating machine for sell

>>

92% Recycled Polyester 8% Spandex Cation Jersey Knitted Recycled Polyester Waterproof Fabric

>>

PLC Control High Viscous Kneader Mixer Sigma Blade Mixer Z Type Kneader Natural Rubber Mixing for Silicone Sealant, CMC

>>

CNC Milling Machine Manufacturer Vertical Machining Center 4 Axis Vertical Milling Machine

>>

IP65 Floating Tube Hydroelectric Generator System Rectifier Controller Combiner Boxes

>>

Cost-Effective Precast Concrete Equipment - Affordable Excellence

>>

Professional manufacturer 168F gx200 gasoline generator spare parts crank connecting rod Assy

>>

Taijia JY-8ST Digital Rebar Locator/Rebar Scanner for Concrete Reinforcement Position

>>

Lovely Colorful Printed Canvas Drawstring Bag for Jewelry (HC00150702001)

>>

Factory Direct Sell 3 Point Rear Mounted Tractor Land Leveler

>>

High quality 4-ply carbon filter disposable face mask anti unpleasant odor nonwoven grey face mask in stock

>>

Plastic Recycling Machine/Crushing Machine/PVC Shredder