|

US$50,000.00-60,000.00

|

1 Set

(MOQ)

|

Basic Info.

Application

Busbar Inspection

Process Usage

Busbar Inspection

Movement Method

Linear Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.09~0.1(mm)

Performance Classification

Economical CNC Machine Tools

Transport Package

Plywood Case

Specification

Length: 12m

Production Capacity

10set/Month

Product Description

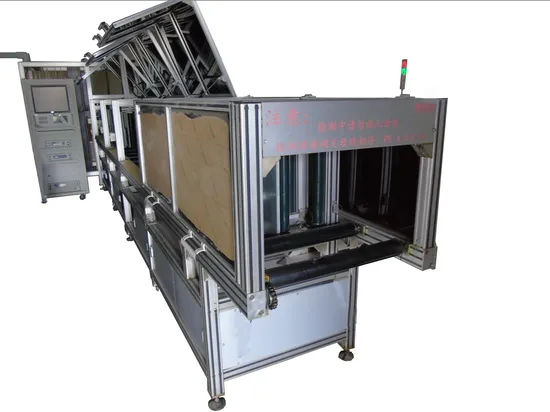

Best sale High speed Compact Busduct Busbar Testing Machinery with skillful manufacture

The automatic busbar inspection line adopts high voltage for busbar voltage and insulation resistance testing.

Specification:

1. suitable for straight compact busbar 630A~2500A, single layer, length 1.5~6m

2. working efficiency: 3min/piece

3. length of inspection line: 12m

Configurations:

1. One set of automatic patching machine;

2. One set of automatic inspection instrument;

3. One set of busbar automatic inspection electrical control system

Features:

1. Automatic end stop structure to align the busbar trunking system;

2. Automatic patching machine for busbar of different phases;

3. Automatic moving, testing and reporting

4. Testing data can be read on computer and printed out;

5. Custom and warranty available;

| Busbar phase and wire | 3P5W\3P4W\3P3W |

| Busbar length | 1.2~6m |

| Nos of inspection fixtures | 3 pieces |

| Housing dimension | L13.5(18)*W0.8*H0.8 m |

| Control mode | PLC or barcode |

| Inspection content | Voltage resistance, insulation, grounding |

| Transformation mode | Internet transform, USB |

| Voltage | 380/415V AC 50/60Hz |

| Total power | 4kW |

| Air source | 0.6MPa |

Manual inspection machine

1. Application for elbow busbars, flange end busbar, straight busbar less than 1m.

2. All the testing data can be recorded on the control system.

Company introduction

We are the company specialized in busbar machine.Busbar machine means busbar production machine or busbar processing machine including mylar sleeve forming machine, busbar assembly machine, busbar riveting machine, busbar testing & inspection machine, busbar packing machine and busbar conveying machine. If you want to know how we use the machine to assemble the busbar, please kindly get the referenced pictures as below.

Step 1 Prepare all busbar finished components

Step 2 Use related busbar machines to process the busbar

Busbar machine copper processing

Need Kiande's busbar gas-hydraulic copper bar punching machine(This is one-time punching forming. In the market, some busbar manufacturer buys three-in-one busbar machine to bend and punch copper or aluminum bar. As the bar experiences many procedures, the accuracy is not good which will cause the phase distance too small to cause the short circuit.)

Busbar machine mylar sleeve processing machine polyester film forming machine

Need Kiande's mylar/polyester film forming machine. In the market, some busbar manufacturer requests workers to wrap the bar manually. Different workers have different workmanship. If employer meets the inexperienced workers, the wrapping part will have some gaps which will cause the short circuit.

Busbar machine busbar accessory 3M insulation film Conductor(Copper bar/Aluminum bar) end wrapping

Busbar machine busbar accessory Aluminum profile capped casting capped end

Busbar machine Busbar riveting machine

Busbar machine busbar inspection machine busbar testing machine

Busbar machine busbar packing machine busbar packaging machine

Busbar machine busbar accessory rivet the rivet is to connect the profiles instead of bolts more stable and strengthen

Busbar machine busbar accessory joint isolator

>>

Silicone Foldable 8 Digits Calculator

>>

HC-S411 Endodontic treatment steps model Medical science endodontic model dental pulp disease clinical teeth teaching model

>>

Mini Horizontal Metal Lathe Machine Torno Manual Gear Head Engine Bench Lathe Machine (KY250)

>>

Drying rack butterfly type red and white clothes rack floor type folding airfoil clothes drying rack

>>

Cassava Starch Specially for Pearl Taro Balls, Sago, Et Cetera

>>

Luxury Double Edge Matte Gold Blade Shaving Razor

>>

HC-M091A Electric standing walking aid/Electric walking trolley

>>

Taijia flowmeter ultrasonic flow meter price/mini water ultrasonic flow meter price with data logger TDS-100M

>>

Fashion Wholesale Embroidery Printing Plain Dyed Black Long Custom Chiffon Mulberry Silk Hijab Scarf

>>

Creality- Cr-6080 Industry Printer, Dual Extrusion in One Nozzle Quasi-Industrial Grade Ultra-Large Printing Size

>>

84211951 Rear bumper bracket (inside) FOR CHEVROLET EQUINOX 2017-2019

>>

Original German LENZE E82EV751K4C200 inverter new spot negotiated price

>>

(RH-1-15KV/38KV) Outdoor Disconnect Switch (Distribution Type)

>>

Wood Based Panel Machinery: OSB MDF HDF Particleboard Chipbaord 40 Layers Hot Press with Automatic Loading&Unloading

>>

Heavy Duty Forged Casting Crane Rail Trolley Wheel with Shaft Assembly

>>

GSK High Performance Plastic Injection Machine for Efficient Production Needs

>>

Batterie HAWKERPZS 12 PzS 1860 Traction battery 40V1860Ah C5

>>

Wholesale hot-dip galvanized toothed steel grating steel grating subway cable trench cover load plug-in mesh steel grating

>>

Ple Hot Selling Fruit Picking Machine Crawler Wheeled Walnut Tree Shaking Tree Picking Machine Fruit Harvester Shaking Tree Trunk

>>

Men's and women's 3D custom hoodies, custom pullovers, front and rear, design your own pictures/texts