|

US$5,600.00-14,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Type

Worktable Milling Machine

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Automatic Grade

Automatic

Certification

CE, ISO 9001

Keywords

Edge Milling Machine

Steel Pate Thickness

6~50 mm

Milling Travel Speed

0.25~0.6 M/Min

Transport Package

Container

Production Capacity

230 Set/Year

Product Description

Product Description

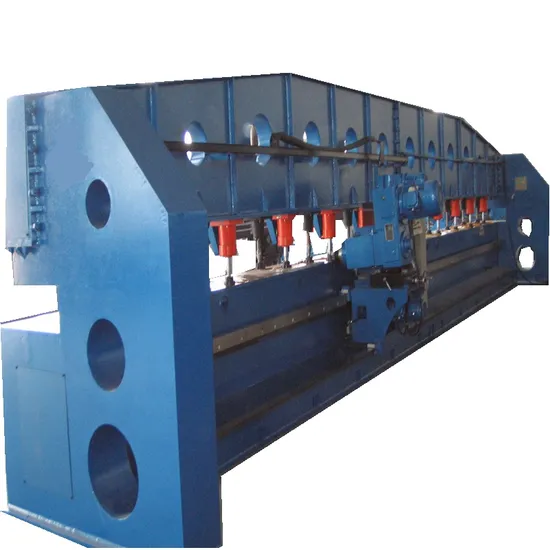

This series machine is a kind of advanced and high efficient milling equipment to prepare the groove of plate before welding instead of planing. Compared with planer, it has the advantages of saving power, low investment and high accuracy of surface finish. It is widely used in the industries as pressure vessel, boiler, ship-building, power plant, petrochemical and machinery, etc.

Product Parameter

| Model | XBJ-3 | XBJ-6 | XBJ-9 | XBJ-12 | XBJ-15 | XBJ-18 |

| Effective milling zone length(m) | 3 | 6 | 9 | 12 | 15 | 18 |

| Milling angle adjustable(^) | 0-45 |

| Applicable steel pate thickness(mm) | 6-50 |

| Max.milling width by on pass(mm) | 8 |

| Milling travel speed(m/min) | 0.25-0.6 |

| Milling return speed(m/min) | 4 |

| Spindle speed(rpm) | 125-630 |

| Hydraulic pressure(mpa) | >=3.5 |

| Number of clamping shoes(each) | 5 | 8 | 11 | 15 | 19 | 23 |

| Pass height(form FL)(mm) | 900 |

| Feeding motor capacity(kw) | 1.5 |

| Hydraulic motor capacity(kw) | 4 |

*We reserve the right to alter specifications without prior notice.

Product Feature

There are single milling head and double milling head; and the milling head can be standard facer or molding facer for your options.

1,The applicable processing sheet size varies greatly;

2,The equipment structure is reasonable in design, good in rigidity and strong in strength;

3,High processing efficiency, especially for larger workpieces, four milling power heads can be involved in the work at the same time, greatly improving production efficiency and shortening processing time;

4,The loading and unloading of the moving upper beam is more convenient and quicker;

5,The hanging line form of the sliding line is safe and beautiful;

6,The main structure is welded parts with tempering to eliminate stress treatment and to avoid deformation phenomenon;

7,The guide rail is arranged in a hanging type and a seat type, which greatly improves the stability of the ordinary suspension type and reduces the vibration phenomenon in the process;

8,The conventional milling machine has its guide rail welded to the bed and processed. Since the bed must be annealed, the surface of the guide rail is soft and affects the service life of the whole machine. The guide rail of the company is made of high-quality 45 steel forging and roughing. Quenching and tempering treatment, and then finishing, quenching and fine grinding, and then fixing to the bed with screws;

9,The milling and pinning feeding mechanism of the machine is driven by frequency motor. The feeding speed of milling and pinning is 0.13-1.2 m/min, and the fast-forward and retreating speed can reach 1.5 m/min, which greatly improves the production efficiency;

10,The milling cutter disc of head of the machine can adopt standard milling cutter disc;

11,The pressing method of the machine adopts hydraulic pressing method, which is convenient and quick;

12,The main transmission parts of the machine are installed inside the cabinet or concealed parts, and the lubrication protection can be effectively guaranteed.

Wincoo Engineering Co., Ltd (WINCOO) is engaged in bringing the most suitable solutions/equipments for client, fabricators, EPC/C companies on pipe fabrication, tank construction, pipeline construction,industrial production lines, clean energy project and other industrial field.

Our Services & Strength

*We have ability of providing workable solutions to support clients to be awarded with shorter project execution time, fewer man-hour cost and higher efficiency construction/fabrication method and better quality during phase of project bidding.*Based client's facility/site space availability, we are able to study/design and present matched configurations on project schedule, quality, cost and productivity to guarantee production pace is accordance with project requirement.*To support project execution, we are always ready to work as fireman to give prompt supply on project materials from different consumables, tools, equipments/machines to special merchandise. With flexibility, we are also glad to perform as procurement agent in China to seek required supply resources.

>>

Open End Rotor Spinning Cover for Textile Machinery

>>

High Quality Sillicon Rubber Sigma Mixer Tilting and Extruding Type

>>

Double-heads wire binding machine for netbooks

>>

Reasonable Price High Efficiency Water Cooled Maiman Jpt 3W 5W UV Laser Marking Machine for Paper Wood Steel Leather

>>

China cheap price noise reduction micro mini hearing aids

>>

Counter Current Refractory Concrete Mixer Machine

>>

Bathroom Sunlight Outdoors PVC Prefab Glamping House Hotel Luxury Geodesic Dome Tent

>>

750mm Black Wall Hung Bathroom Vanity Cabinets

>>

Temperature Humidity Meter, LCD Electronic Digital Outdoor/Indoor Thermometer Hygrometer with Clock Time Humidity Monitor for Home, Bedroom

>>

Garment Fabric Twill Woven Fusing Interfacing Interlining

>>

18W IP65 24V Building Building Facade Strip Wall Washer DMX RGB RGBW LED Wall Washer

>>

Evergreen Maritime Ship Launching Airbag

>>

Picking Lift Cart for Greenhouse Tomato

>>

2021 Hot Sale Cute Study Desk Lamp Mini Rechargeable Portable Flexible Lamp For Bedroom Baby Room

>>

China Factory Diesel Engine /Spareparts Fuel System Pump /Common Rail Auto/Pump Gasoline / Car Injection Engine Fuel System Diesel Engine Nozzle Injector

>>

Precision Casting Mold Processing Aluminum Alloy Casting Parts Die Cast Chair Parts

>>

360-Degree Rotating Double-Sided Magnetic Whiteboard for Versatile Use

>>

NEMA 5-15P POWER CORD

>>

Constant Temperature And Humidity Floor Type Chilled Water Air Cabinet

>>

PP honeycomb panel equipment production line