Product Details

Product Description

Product Description

Product Description

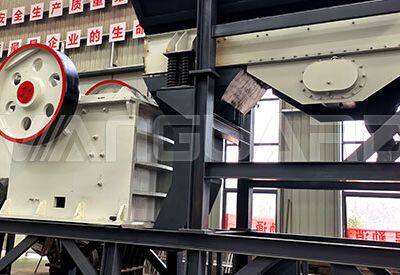

Factory Price Stone Rock Lime Jaw Crusher Breaker Crushing Plant

MBP series jaw crushing plant uses the optimized frame structure and movable jaw design, mainly used for the coarse crushing of minerals and rocks. According to the different production capacity, it can be designed and matched with different specifications of the feeder, jaw crusher, belt conveyor and other modular structural parts.

PRODUCT PARAMETERS

Project

| Device Name

| Models and Specifications

| Power (KW)

| Amount

|

|

C106 Jaw Crusher

+

ZSW4211 Feeder

| feeding machine

| equipment

| ZSW4211

| /

| 1

|

motor

| Standard

| 15

| 1

|

jaw crusher

| equipment

| C106

| /

| 1

|

triangle belt

| Standard

| /

| 10

|

motor

| Standard

| 110

| 1

|

Modular steel structure

|

| Standard

| /

| 1

|

main conveyor

| Specification

| B1000*12m

| 11

| 1

|

drive mode

| electric drum drive

| /

| 1

|

magnetic separator

| Specification

| RCYQ-10

| 2.2

| 1

|

drive mode

| reducer

| /

| 1

|

Electrical System

| Electric control cabinet

| Feeder motor variable frequency speed regulation, host soft start, electrical components Chint

| /

| 1 set

|

|

|

| /

| 1 set

|

Hydraulic Pumps, Valves, Stations and Tubing Accessories

|

| /

| 1 set

|

Total power 138.2KW

|

Project

| Device Name

| Models and Specifications

| Power (KW)

| Amount

|

|

PE57 Jaw Crusher

+

ZSW3090 Feeder

| feeding machine

| equipment

| ZSW3090

| /

| 1

|

motor

| Standard

| 11

| 1

|

jaw crusher

| equipment

| PE57

| /

| 1

|

triangle belt

| Standard

| /

| 5

|

motor

| Standard

| 55

| 1

|

Modular steel structure

|

| Standard

| /

| 1

|

main conveyor

| Specification

| B650*12m

| 5.5

| 1

|

drive mode

| electric drum drive

| /

| 1

|

magnetic separator

| Specification

| RCYQ-6.5

| 1.5

| 1

|

drive mode

| reducer

| /

| 1

|

Electrical System

| Electric control cabinet

| Feeder motor variable frequency speed regulation, host soft start, electrical components Chint

| /

| 1 set

|

|

|

| /

| 1 set

|

Hydraulic Pumps, Valves, Stations and Tubing Accessories

|

| /

| 1 set

|

Total power 73KW

|

Project

| Device Name

| Models and Specifications

| Power (KW)

| Amount)

|

|

PE69 Jaw Crusher

+

ZSW3896 Feeder

| feeding machine

| equipment

| ZSW3896

| /

| 1

|

motor

| Standard

| 11

| 1

|

jaw crusher

| equipment

| PE69

| /

| 1

|

triangle belt

| Standard

| /

| 5

|

motor

| Standard

| 75

| 1

|

Modular steel structure

|

| Standard

| /

| 1

|

main conveyor

| Specification

| B800 * 12m

| 7.5

| 1

|

drive mode

| electric drum drive

| /

| 1

|

magnetic separator

| Specification

| RCYQ-8

| 1.5

| 1

|

drive mode

| reducer

| /

| 1

|

Electrical System

| Electric control cabinet

| Feeder motor variable frequency speed regulation, host soft start, electrical components Chint

| /

| 1 set

|

|

|

| /

| 1 set

|

Hydraulic Pumps, Valves, Stations and Tubing Accessories

|

| /

| 1 set

|

Total power 95KW

|

Special Design of different models of the mobile crushing plant will be available upon request.

PRODUCT EXHIBITION

PRODUCT ADVANTAGES

Rugged construction

The frame is divided into welding type and assembled type. The small and medium-sized specifications generally adopt the welding type, and the large-scale specifications generally adopt the assembled type.

The welding type adopts large arc transition fillet and low stress area welding method, which has the characteristics of impact resistance, uniform force and low failure rate.

Superior cavity design, large feeding granularity

The V-shaped crushing cavity design is adopted, the toggle plate has a large inclination angle and a large stroke. Compared with the traditional PE series jaw crusher, it has the larger feeding particle size, the higher output, more uniform the particle size, and reduced the jaw plate wear.

Integral bearing seat

The integral cast steel bearing seat structure ensures complete coordination with the frame, which makes the bearing run more smoothly and avoids unnecessary radial load on the bearing during the tightening process of the combined bearing seat.

Anti-vibration installation design

The crusher is fixed by a special rubber shock absorption device, which effectively absorbs the peak vibration of the equipment and allows the vertical and longitudinal displacement of the crusher, thereby reducing the impact on the foundation.

PRODUCT APPLICATION

Processed Material:Limestone, Granite, Basalt, River Stone, Quartz, Copper Ore, Iron Ore, Marble.etc

CUSTOMERS' SITES

Packaging and Shipping

About VANGUARD

Zhengzhou Vanguard Machinery Technology Co., Ltd. is a professional high-end equipment manufacturing enterprise integrating R&D, production and sales. Its business scope covers sand and gravel aggregates, industrial grinding powder, mobile crushing plant, mineral processing machine, EPC general contract project, etc. Our factory covers 110000 square meters and our products are sold to more than 100 countries, being the popular manufacturer in global mining industry.

Matching of production and support system allows customers to get the best service at the lowest cost.

Qualification

All of our products have passed ISO9001-2008 international quality management system certification, European CE certification and Russia GOST certification, and our company has established a fully controlled quality management system. We are playing a leading role in quarry mining, sand making and industry powder producing fields.

Our Services

FAQ

Q1: what will you do if the machine is broken down? Does your company supply the spare parts?

A: The Products warranty is 12 months. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. And we will supply the spare parts with high quality for you at lowest cost.

Q2: How long is your delivery time?

A: The lead time is 10-30 days. Delivery time will vary depending on the type of the machine, availability and shipping method.

Q3:What is the shape of the aggregate made by your company's crusher?

A: The shape of the aggregate is related to the design of the crusher or the complete stone production line. Our engineers will

design the most suitable proposal based on raw materials.

Q4: How about the quality of your equipment?

A: Our products are manufactured strictly according to national and international standard, and we will take a test on every set of machine before delivery.

Contact Information

Contact Us:

Email: sales@vanguardtec.com

Tel: +86 15690852006 (WhatsApp/Wechat)

Website:

24/7 online services. Get free proposal and best price Now!

>>

Superior Concrete Power Trowel Machine

>>

China Zeyu Heavy Industry King of Cost Performance Hls60 Concrete Mixing Plant

>>

17.3 Inch High Quality Extra Thin Motorized Flip up Monitor Lift Easy to Operate and Stable in Conference System

>>

Compressed Sofa Compression Kit for DIY Luxury Modern Sofas

>>

Heat Treatment Annealed Easy For Forming Products Stainless Steel Precision Tubes 304 316 316L 309 310 310s SS Seamless Tube

>>

2023 latest Design 12 Inch 300mm Diamond Saw Blade Cutting Disc for Granite Marble Stone

>>

Premium Metal Acrylic Satin Series Insert Room Signs for Door Wall

>>

10 Wells Oil Watercolor White Round Plastic Pallet Palette for Student

>>

304 316 Stainless Steel Press Flange and Loose Flange

>>

Chinese Agriculture Rice Combine Harvester 688q Mini Rice Combine Harvester Paddy Beans Harvester Kubota Used 90% New Machinery

>>

New Invention Best Selling Agricultural Pto Driven Hydraulic Adjust Satellite Agri Land Grader Laser Leveler

>>

CNC70 Automatic Pipe Cutting Band Saw Machine

>>

Facial Tissue Log Saw Cutting Machine

>>

Sqmg New Design Self Loading 2.6 Cubic Meters Concrete Mixer with Loader 3.5cbm Drum

>>

Automatic New Potato Harvester Tractor Potato/Sweet Potato/Onion/Carrot Harvester 4ux-100

>>

Front Bumper Auto Parts E Class W212 Car Engine Hood For W212 Body Kit

>>

Vertical Mini Wrc28vm Wheel CNC Lathe Diamond Cutting Tools

>>

M1080b Outer Diameter Cylindrical Grinding Machine Tool

>>

SHENGKEG New Designs Lady Square Watch K0170L-1Women Stainless Steel Mesh Watch Charming Rhinestone Watch

>>

Industrial Mining Impact Rock Crusher Copper Gold Ore Stone Impact Crusher Price