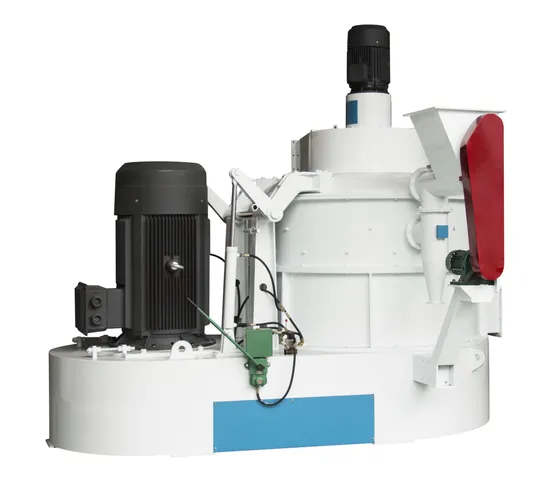

Basic Info.

Cutter Material

Hard Alloy

Object

Coal, Metal, Plastic, Wood, Grain and Chemical Raw Materials

Degree of Comminution

60-1200 Mesh

Transport Package

Seaworthy Packaging

Production Capacity

500-2000kg/H

Product Description

Application Ultra-micro pulverizers can be used to grind a wide range of chemical substances, particularly suitable for the following types:

1. **Resins**: Includes various natural and synthetic resins used for manufacturing fine chemicals and composite materials.

2. **Pigments**: Such as organic and inorganic pigments, used to improve pigment dispersion and coloring effects.

3. **Coatings**: Includes raw materials for powder coatings and water-based coatings, enhancing the quality and coverage of the coatings.

4. **Plastics**: Used for grinding plastic granules to better suit further processing and compounding.

5. **Cosmetic Ingredients**: Such as talcum powder and alum, used in the preparation of various powdered cosmetics.

6. **Pharmaceutical Intermediates**: Grinding various pharmaceutical intermediates to improve the efficiency and quality of drug preparation.

7. **Pesticides**: Grinding solid pesticides to increase their effectiveness and uniform distribution in agricultural applications.

Grinding these chemical substances enhances the reactivity and uniformity of the raw materials, playing a critical role in the manufacturing process of various chemical products. The use of ultra-micro pulverizers not only improves product quality but also effectively reduces production costs and enhances production efficiency.

The material that has undergone initial cleaning and magnetic separation enters the crushing chamber through the spiral feeder for crushing. Due to the high-speed rotation of the grinding disk, the material is crushed by the impact of the hammer blade mounted on the grinding disk under the action of centrifugal force, and then spun at a very high speed onto the surrounding gear ring. Due to the small gap between the hammer blade and the gear ring, it is further crushed here. The crushed material is carried between the inner wall and the splitter cover by the airflow entering from under the crushing disc, and then enters the classification chamber. It is classified by the combined action of wind, gravity, and centrifugal force of the classification wheel. The separated coarse material returns to the crushing chamber from the inner cavity of the splitter cover and is re crushed. The fine material (finished product) is sucked into the classification impeller, enters the discharge chamber, and enters the air mesh system from the discharge port.

Product Parameters Our Clients

company profile

workshop

Other Product

FAQ 1. How can I know your quality?

Our company is famuous in our industry. We have more than 10 years history. The best way to know the quality is comparison. You can come to our factory for on-the-spot investigation. You are welcome.

2. Can you supply sample test?

Of course our company can supply sample test before buying. And record the testing result and send to you by pictures or video.

3. What is your delivery time if I place order?

Usually 30~60 days. It depends on the machine itself, our actual order status.

4. Can you supply installation and commissioning service abroad when we received our equipment?

Yes, our company can send our engineers to your local workshop to guide installation and commissioning and training your operators.

5. How to operate and maintain the machine?

We will give you operation manual, drawing, circuit diagram spare parts list, etc after shipping.

6. What should I do if we can not solve the problems some times?

You just need to send email or make a call to us. We will reply within 12 hours and analyse the problems with you. Find the reason and find the way.

If we can not solve by communication after trying several ways, we can send our engineer to your place if you need.

7. What is your warranty period?

We supply one year warranty and life time after sales service for our euqipment.

It's the right time to E-mail and Make a Call Now!

>>

Leyo V10 Vertical Machining Center V10 Machining Center

>>

Transmission Safety Diving Rotating Digital Reverse Marine Fishing Accessories Protective Gear

>>

100% Original Model 2 3 4 Buttons Remote Replacement Car Key Blank Car Key Shell for Toyota Corolla Camry Matrix Yaris RAV4 Key Toy43

>>

Multi Needle Embroidery Designs Collections for Machines

>>

Electric Abdomen Massager with EMS Pulse Heating Belt Menstrual Pain Relief Device

>>

ISO Certificate Building Materials Cold Color PPGI Steel Metal 270 Roof Sheet Ridge Cap Roll Forming Machine with PLC

>>

Automatic Hydraulic Bottle Preform Pet Making Machine Injection Moulding Equipment

>>

H Type Chicken Cage Layer Hens Cage Automatic Equipment Battery Pullet

>>

Jugao Hydraulic Metal CNC Swing Beam Shearing Machinery Iron Plate Cutting Machine

>>

Industrial Bread Making Machines Planetary Mixer

>>

Hot sale good quality Soil Compaction Testing Non-nuclear Density Gauge manufacturer price

>>

Waterproof Exterior Wall Cladding Building Materials Aluminium Composite Panel

>>

Men′s 100% Cotton Print or Solid T-Shirt

>>

Multifunctional CNC Wood Acrylic Stainless Steel Engraving Laser Cutting Machine Fiber for Wholesales

>>

WECOIL HCT-1280 8mm 12-16 axis CNC Camless Agricultural Torsion Spring Machine

>>

Floor Type Radial Hydraulic Drilling Machine Z3063X20 Heavy Duty Drill Machinery

>>

Wholesale 90 120 Degree Black Stainless Steel L Angle Bracket Corner Bracket For Fence Shelf Bed Cabinet Furniture

>>

Racing Car Metal Model Crafts Collection

>>

Dog Grooming Cat Striped Bow Tie Animal Bowtie Collar Pet Adjustable Neck White Necktie For Party Wedding

>>

Handheld 1200W High Power Ultrasonic Welding Machine Small Ultrasonic Hand Welder Portable Spot Welder Equipment