Basic Info.

Plasticizing Way

Screw Type

Certification

CE, ISO9001:2008

Injection Weight (G)

3359 G

Plasticizing Capacity(G/S)

136

Screw Diameter (mm)

100 mm

Injection Rate (G/S)

849 G/S

Mold Height(mm)

350 - 950 mm

Ejector Stroke(mm)

250 mm

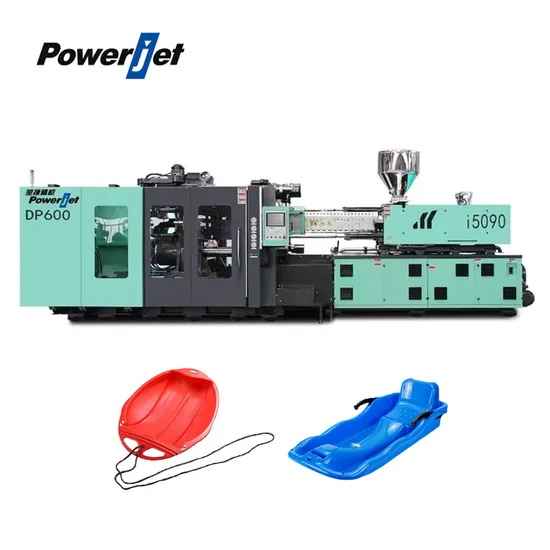

Product Description

Details Images

High Efficiency

Low Energy Consumption

More Dedicated

The high-pressure clamping adopts movable platen clamping structure, which is fixed by a high-pressure tie bar, which is reliable in sealing, does not leak oil, and the tie bar is durable.

The ejector cylinder contains a converted structure, which ensures the whole machine more short and occupy less space.

Innovative holding brake structure, adjusting the holding brake with high speed and reliability, low noise and accurate synchronization.

Four independent high-pressure oil cylinders innovative structure for quick and stable pressure rising and releasing, easy maintenance.

Large mold opening stroke, high-speed and stable mold opening and closing, high efficiency.

Ultra-wide space of the mold clamping area, large core pulling space and easy operation.

The mold clamping unit is automatically lubricated with grease, clean, low maintenance cost, simple and convenient.

The movable platen adopts linear guider with low resistance, low energy consumption, stable moving and accurate positioning.

Equipped with servo electric charging, high speed rotate, low noise, low energy consumption, compared with traditional hydraulic motor charging, saving power cost more than 30%.

Product Paramenters

DESCRIPTION

| UNIT

| DP600-S6

|

Intemational size rating

|

| 5090-600

|

Clmping force

| KN

| 6000

|

Opening Stroke

| mm

| 1450/850

|

Space btw.Tie Bars

| mm

| 960×860

|

Daylight Max.

| mm

| 1800

|

Mold Thickness(min-max)

| mm

| 350-950

|

Ejection Stroke

| mm

| 250

|

Ejector Force

| KN

| 166

|

Screw Diameter

| mm

| 100

|

Short Volume

| cm3

| 3691

|

Shot Weight(PS)

| g

| 3359

|

Injection rate

| g/s

| 849

|

Injection Pressure

| MPa

| 138

|

Screw L/D Ratio

| L/d

| 20

|

Injection Stroke

| mm

| 470

|

Screw Rotary Speed max.

| rpm

| 145

|

Nozzle Contact Force

| KN

| 200

|

Nozzle Stroke

| mm

| 600

|

System Pressure

| MPa

| 17.5

|

Pump Motor

| KW

| 52+42

|

Heating Capacity

| KW

| 47

|

Oil Tank Capacity

| L

| 1000

|

Machine Dimensions

| m

| 7.9*3*2.7

|

Machine Weight

| T

| 25

|

Company Profile

POWERJET PLASTIC MACHINERY CO., LTD. is a high and new technology enterprise of R&D, manufacturing, sales, after-sales service of injection molding machine and blow molding machine. Powerjet was founded in 2000,occupying an area of 130,000 square meters. Annual production capacity has reach to 4000-5000 injection sets of. More than 20 offices have been set up in the global market, machines have been exported to more than 60 countries in the world. The machine specifications are complete, adapt to a variety of industries, cost-effective, and create high returns for customers. One-stop whole-process caring service.

Established distributors in multiple countries like Thailand, Malaysia, Indonesia, Vietnam, Uzbekistan, USA, Mexico, Brazil, and Pakistan, etc. With a global sales network, our local offices and agents can provide more convenient and sincere services. Agent In Worldwide

Setting Up Agent In More Than 20 Countries For Sales And Support

Lifetime Support

24 Hours Online Service And Overseas Installation & Maintenance

Spare Parts

We Supplying Screw, Motor, Control Panel And Plastic Mold For Machines

Operation Training

Support Training To Engineer For Setup, Processing & Troubleshooting

Plastic Mold Testing

Provide Testing Mold Service Before Customer Receiving The Machine

Project Cases

FAQ

Q1: Are you a manufacturer or trading company?

A1: We are a factory for plastic machines. Over 24 Years Experience In Manufacturing Injection Molding Machine And Blow Molding Machine.

Q2: Delivery time

A2: Normally Machine Delivery from the factory in 0-60 days after receiving the down payment. (During Chinese Public Holidays like National Day or Chinese New Year, the delivery time should be 10-30 days longer accordingly).

Q3: Where is your factory located?

A3: Our factory is located in No.5 Chuangxin Xi Road, Leping Town, Sanshui District, Foshan City, Guangdong Province, China. 1h drive from Guangzhou to our factory. Welcome to visit our factory.

>>

New Product Pleating Machine Knife Pleating Machine Plgt-420

>>

Cosmetics Factory Price Hot Scent Spicy Long Lasting Business Man Perfume

>>

Factory Direct Supply Dried Flower Gypsophila for Wedding Home Decoration

>>

Altama Camouflage Suede Leather Mens Boots

>>

Fully Automatic Vertical Servo Drilling Machine

>>

Activewear Manufacturer 2021 New High Waist Yoga Leggings Black Gilded Yoga Pants

>>

Lower Price Module with Bearing and Without Bearing

>>

digital car temperature sensor SHT11

>>

Tunnel Automatic Powder Coating System with Spray Booth

>>

Collapsible Stainless Steel Hot Smart Cookware Handle Camping Multi Function Clear Big Cooking Pot

>>

Generators radiator 12M33D748E310 12M33D792E310 12M33D902E310 12M33D968E310 12M33D1108E310 12M33D1240E310 16M33D1400E310

>>

Wholesale Free Design OEM Custom Printed Logo Wireless Earphone Electronic Paper Foldable Packaging Boxes With Clear Window

>>

Outdoor Garden Metal Animal Life Size Statue Bronze Stag Deer Sculpture

>>

3.95inch IPS 480*480 RGB Interface Square TFT Display SPECIAL LCD Screen

>>

3 Way DN25 Brass Anti-Condensation Mixing Valve For Protect Solid Fuel Boilers

>>

Heavybao Stainless Steel Cooking Restaurant Deep Fryer Oil Filter Cart Machine Mobile Oil Filter Cart Machine for Fryers

>>

Ergonomic Sugar Conical Mixer Automatic Twin Cone Blending Equipment

>>

REVO Timing Kit Chains Auto Accessories for Opel Agila A Astra G Astra H TK1001-54

>>

G60 TWS Earphone 2025

>>

Welding Work Boots for Men Steel Toe Safety Boots Soft Men′s Non Slip Steel Toe Shoes Lightweight Slip on Working Shoes Indestructible Construction Welder Boots