|

US$100,000.00-150,000.00

|

1 Set

(MOQ)

|

Basic Info.

Pipe Material

Carbon Steel

Theory

High Frenqucy Welded

Application

Industry, Decoration, Construction

Type

Pipe Production Line

Name

Pipe Welding Production Line

Certification

ISO9001 & CE

Pipe Type

Round & Square & Rectanglar Pipe

Welding Mode

High Frenqucy Welded

Pipe′s Thickness

0.5 - 20mm

Transport Package

Safe Packaging

Production Capacity

50 Set/Year

Product Description

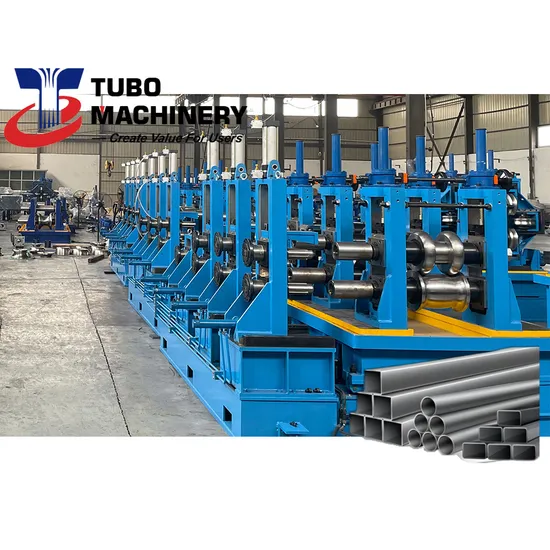

Spiral Steel Pipe Making Machine Oil/Gas Pipe Welding Production Line Price

Our Product Advantage:

1. High Precision

2. High Production efficiency,Line speed can be up to 120m/min

3. High Strength,The machine works stably at a high speed, which improves product quality

4. High Good product rate, reach to 96.5%

5. Low wastage, Low unit wastage and low production cost

Which Kind of Pipe Can be Produced by Our Pipe Mill ?

1. Wire and Cable Protection Pipe

2. Heating Pipe

3. Structural Support Steel Pipe

4. Low-pressure Process Pipeline

5. Industrial Steel Pipes

6. Low Pressure Fire Fighting Pipeline 7. Decoration Pipe

8. Sewage Pipes

9. Water Pipe

10. Steel Scaffolding Pipe

11. Building pipe

Model List of Tube Mill

| Model | Round Pipe | Square&Rectanglar Pipe | Speed

m/min |

| Diameter(mm) | Thickness(mm) | Diameter(mm) | Thickness(mm) |

ERW32

| 10 - 38mm

| 0.5 - 2.0mm

| 10×10 - 30×30mm

| 0.5 - 1.6mm

| Max.120m

|

ERW50

| 15 - 51mm

| 0.5 - 2.5mm

| 15×15 - 40×40mm

| 0.5 - 2.0mm

| Max.120m

|

ERW60

| 16 - 60.3mm

| 0.5 - 3.0mm

| 15×15 - 50×50mm

| 0.5 - 2.5mm

| Max.120m

|

ERW76

| 20 - 76mm

| 1.0 - 4.0mm

| 20×20 - 60×60mm

| 1.0 - 3.0mm

| Max.120m

|

ERW89

| 25 - 89mm

| 1.0 - 4.5mm

| 20×20 - 70×70mm

| 1.0 - 3.5mm

| Max.120m

|

ERW114

| 38 - 114mm

| 1.0 - 5.0mm

| 40×40 - 90×90mm

| 1.0 - 4.0mm

| Max.80m

|

ERW165

| 60 - 165mm

| 2.0 - 6.0mm

| 50×50 - 150×150mm

| 2.0 - 5.0mm

| Max.60m

|

ERW219

| 89 - 219mm

| 3.0 - 8.0mm

| 80×80 - 200×200mm

| 3.0 - 8.0mm

| Max.50m

|

ERW273

| 114 - 273mm

| 4.0 - 10.0mm

| 100×100 - 250×250mm

| 4.0 - 10.0mm

| Max.40m

|

ERW325

| 165 - 325mm

| 4.0 - 12.7mm

| 100×100 - 300×300mm

| 4.0 - 12.0mm

| Max.30m

|

ERW426

| 219 - 426mm

| 5.0 - 14.0mm

| 150×150 - 350×350mm

| 5.0 - 14.0mm

| Max.30m

|

ERW508

| 219 - 508mm

| 6.0 - 16.0mm

| 200×200 - 400×400mm

| 6.0 - 16.0mm

| Max.25m

|

ERW610

| 325 - 610mm

| 6.0 - 18.0mm

| 250×250 - 500×500mm

| 6.0 - 18.0mm

| Max.25m

|

ERW720

| 355 - 720mm

| 6.0 - 20.0mm

| 300×300 - 600×600mm

| 6.0 - 20.0mm

| Max.25m

|

Process Flow

Steel Coil→→ Uncoiler →→Shear & Butt Welding →→Accumulator →→ Forming Section(Main driving unit + Flattening unit & Feeding guide + Forming section) →→ Welding Section (Seam guide stand + High frequency induction welding system+ Squeeze roll welding stand + External bead scarfing + Seam grinding stand)→→ Emulsion Water Cooling Section →→ Sizing mill (Main driving unit + Sizing section + Speed testing unit + Turkey heads straightener)→→ Cutting Saw →→ Run-out Table & Packing Device.

Product Description

Step 1: Uncoiler

Function: Support rolled plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum,brake.

There are 3 types: Pneumatic/Hydraulic / Manual.

Step 2: Shear & Butt Welding

Function: Shear the end of each strip coil, then welding them together, so that pipe making welding machine line can be continue production.

There are 2 types: Automatic / Manual

Step 3: Accumulator

Function: Storage strip to keep continue production.

There are 2 types: Horizontal / Vertical

Advantage:

Horizontal type can be larger storage.

Vertical type is much cheap and small space occupied.

Step 4: Forming Section

Function: Forming the tube from strip

Advantage: >Advanced forming technical >One-stage molding platform >Reliable quality gear box >Siemens Beide motor

Step 5: High Frequency Welding

Function: Welding the pipe , different thickness & diameter, the power of the HF welding machine welder

Our advantage: We choose the China best welder

Step 6: Sizing Section

Function: Sizing the tube to precise size

Advantage: >Advanced sizing technical >One-stage molding platform >Reliable quality gear box and Siemens Beide motor >High precision, low error of the pipe size

Step 7: Cutting Saw

Function: Cutting the tube mill line tube to right length.

There are 2 types: Fly saw / Cold saw

Advantage: Fly saw: Easy to operation, low investment. Cold saw: No noise, no burr cutting precision and cross section.

Step 8: Run Out Table & Stacking Machine

Function: For output and packaging of products

There are 2 types: Automatic / Manually

Alternative - Packing Machine

Function: Automatic packing machine is used to collect, stack steel pipe into hexagon or Square Shape, and bundle automatically. It runs stably without manual operation. Meanwhile, eliminate the noise and knocking of shock of steel pipes. Our packing line can improve your pipes quality and production efficiency, reduce cost, as well as eliminate potential safety hazard.

Advantage: Stacking and Bundling AUTOMATICALLY Perfect surface tube Less labors, Lower working strength Automatic operation, lower noisy

Successful Project

Workshop

Exhibitions & Customer Visits

Packaging & Shipping

Our Advantages

FAQ

1. Q : Are you manufacturer ?A: Yes, We are manufacturer . More than 20 years R&D and Manufacturing Experience. We use more than 130 CNC machining equipments to guarantee our products perfect.

2. Q: What payment terms do you accept?

A: We are flexible on payment terms, please contact us for details.

3. Q:What information do you need to supply a quotation?

A: 1.Maximum Yield Strength of the material

2.All pipe sizes needed (in mm)

3.Wall thickness (min-max)

4. Q: What is your advantages?

A: 1. Advanced mould share-use technology (FFX, Direct Forming Square). It saves a lot of invest amount.

2. Latest quick change technology to increase the output and reduce labor intensity.

3. 130 CNC machining equipments to guarantee our products perfect.

4. More than 20 years R&D and Manufacturing Experience. 5. Customized According to Customer Requirements.

5. Q: Do you have after sales support?

A: Yes,we have. We have a 10-person -professional and strong installation team.

6.Q: How about your service?

A: 1. One year's warranty.

2. Providing spare parts for life time at cost price.

3. Providing Video technical support, Field installation, commissioning and training, online support, Engineers available to service machinery overseas.

4. Provide technical service for facility reforming, refurbishment.

>>

Custom Logo Acrylic 5 Panels Snapback Cap

>>

Small Manufacturing Machines Tissue Toilet Paper Making Machine Price/Paper Mill Machinery

>>

European Standard Size Impact Windows Hurricane Proof Casement Window

>>

100Pcs Stabilized Wooden Dominoes Block Game

>>

Agricultural Machinery Parts Disc Track for Claas Sheaf-Binding Reaping Machine

>>

9 Inch aluminum handle stainless steel camping folding tactical knife

>>

Automatic rewinding tissue roll small toilet paper making machine price (0086-18037126904)

>>

CNC Milling Machine with CE Certificate Vmc960 CNC Machine Tools

>>

Universal Portable Mobile Phone Tablet Laptop Computer Wireless Bluetooth Keyboard

>>

High Quality CD 1ton 2 Ton 5 Ton 10 Ton Traveling Wire Rope Electric Hoist with Remote Control

>>

HC-S222 Natural Size Knee Joint Model/Knee Skeleton Model/Plastic Knee Anatomy Model

>>

Cheap Price Plastic 6-Cavity Pet Essential Oil Drip Bottle Stretch Blow Moulding Machine

>>

Full Ex-Proof Vertical Planetary Kneader Mixer for Rocket Propeller Material Kneading Machine

>>

wire nail making machine nail production line factory price

>>

thermoforming black plastic blister trays plastic PET perforate blister pallets

>>

High Quality 5L Short Path Distillation with Competitive Price

>>

Versatile CNC Gmc Gantry Milling Machine with Extended X Axis

>>

1000L Emulsion Paint Dispersing Mixing Machine High Speed Dissolver Hydraulic Lifting Disperser

>>

HC-I040 ABS trolley type Medical HD camera video Endoscope System with Gastroscope and Colonoscope

>>

Decorative Hole Perforated Metal Mesh Stainless Steel Sheet for Ceiling Tiles