|

US$140,000.00-700,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Material Processed

Rubber

Computerized

Computerized

Certification

ISO9001:2008, CE

Gear Box Cooling

by Water

Safety Design

with PLC Auto Control

Transport Package

Film with Wooden Pallet

Product Description

Product Description

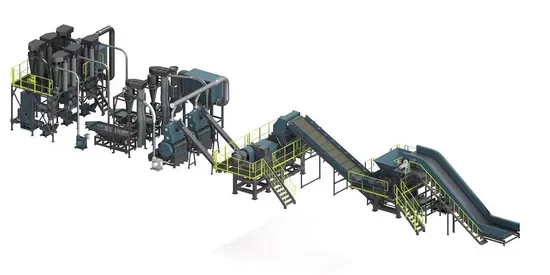

The Waste Tire Recycling Line can handle the used tires. It recycles rubber, steel wire, and fiber from tires using a room temperature treatment process.

It consists of a tire crusher, steel wire separator, disc sorting system, rubber crusher, miller, fiber sorting system, magnetic separator, screening equipment, dust collection system, cooling system, and automatic control system.We can tailor the solution to your specific needs. Capacity ranges from 1-20ton/hr. Rubber products are 8-200 mesh.

Working Process

1. Evenly convey tires into the double-shaft Shaft Shredder.

2. The shredder can handle tire shreds as small as 80mm.

3. Tyre shreds larger than 80mm are returned to the shredder via the back feeding system.

4. Tyre shreds smaller than 80mm will be sent to the Rasper, where they will be crushed into materials smaller than 18mm. They will be filtered, yielding a mixture of rubber chips and waste steel wire.

5. It will separate the steel wire from the mixture using a magnet separator. The rubber chips will be crushed by a rubber granulator.

6. High-speed rotors crush the rubber chips into 1-6mm rubber granules.

7. Different sizes of rubber granules and rubber powder will be separated.

8. The Miller will grind rubber granules into 20-80 mesh rubber powder.

9. It includes a dust collection system for dust, powder, and waste fiber.

10. The entire line is automated. It's secure, stable, and dependable.

Detailed Photos

Product Parameters

A tire shredder can shred scrap tires (small car tires, half wire tires, full wire tires, engineering tires, etc.) into 20-200mm rubber blocks, the size of the rubber block can be adjusted to your requirements. There are two ways to feed material--using a conveyor or the grabbing machine. The large volume tires can also be configured with a tire feeding pressure system to improve production efficiency.

The tire rasper is mainly used for scrap tire processing, the size of the rubber block should be below 60mm. The rotor knives cut the rubber and steel wire away from the machine through medium-speed rotation. Then we get the wire mixture of the rubber and waste steel below 12mm. With the subsequent processing process,we can sort out rubber from waste steel wire.

The rubber crusher can crush the rubber block into rubber particles below 6mm by rotating at high speed.

Certifications

>>

Auto Grinding Machine Manufacture Stainless Steel 304 Milling Machine Pulverizer Fineness Powder Crusher Equipment

>>

New Products Cream Pump Serum Pump

>>

HC-C013 New Products IRelax homecare Personal Stress Management Device with best price for sale

>>

Black Custom Car Cover, Dust, Sun and Waterproof Cover

>>

RELIANCE 802273-14R brand new in stock

>>

New design heavy duty garage hooks 10 pack 12 pack garage utility hook

>>

High Precision Bevel Drill Sharpener with Electric Motor and Grinder

>>

4pcs Inflatable Pool Inflatable Pool Fighting Float for 2 Players Fighting Float Row Toys Battle Log Rafts

>>

Claw Hammer 16oz Heads Titanium Magnetic Martillos De Mano Straight Claw Hammer

>>

5 Axis CNC Router Machine Woodworking High Quality CNC Router 5 Axis Wood Router CNC Mac

>>

Precision Grinding

>>

4-6 High Speed Brc Wire Mesh Welding Machine

>>

Full-Automatic Head Loop N95 Cup Anti Dust FFP3 Mask Making Machine

>>

New Design PE Food Grade Plastic Sheet with Cutting Board

>>

Byloo 2022 2023 Outdoor EVA Fishing Bags Folding Fish Protection Bucket 14 GALFish Bucket Bag

>>

900 Ml Bag Laundry Detergent Silver Environmental Protection Formula Custom Laundry Detergent

>>

Weight Ms Square Steel Pipes Hollow Section Pipes 20X20 25X25 30X30 40X40

>>

BM55/6 FINCM Guaranteed Quality Easy Operate H Beam Cnc Beam Drilling Machine

>>

Concrete Pumping Construction Machinery Trailer Mounted Pump

>>

4 Cavities Semiautomatic Blow/Blowing Molding/Molding Machine/Plastic Machinery/Plastic Machine/ Blowing Machine/Water Machine