|

US$200,000.00-450,000.00

|

1 Set

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Lead Time

120 Days-150 Days

Transport Package

Seaworthy Packing

Production Capacity

200sets/Year

Product Description

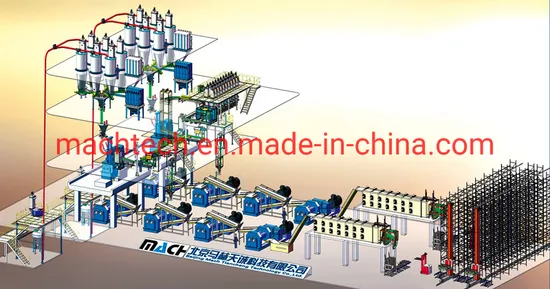

PLC Control Mixer Rubber Processing Machine Automatic Batching System

Major functions of the whole mixing process managing and control system

Δ Raw material Management

Δ Production Schedul Management

Δ Production Recipe Management

Δ Mixing Optimization Function

Δ Data Report Management

Δ Dynamic Real Time Monitoring

Δ Quality Tracing Function

Δ System Alarm Prompting Function

Δ Fault Dagnosis Analysis

Δ Remote Monitoring Function

Main Technical Parameters

| Carbon black scale -weighing range | 30/50/200/200 Kgs |

| Oil scale -weighing range | 10/20/30/40/50 Kgs |

| Rubber scale-weighing range | 100/150/200/300/400 Kgs |

| Powder scale weighing accuracy | Static≤±0.1% F.S, dynamic≤±0.2% F.S. |

| Weighing cycle time | ≤90-120s/ batch |

| Carbon black- pneumatic conveying capacity | 3-15t/h |

| Oil injection pressure | 2-6 Mpa |

| Oil conveying temperature | 0-85ºC |

| Processing oil injection, carbon black and major ingredients discharging cycle time | ≤20s |

| Dust contents in tail air after dust removal system | ≤8mg/m3 |

| System equipment noise | <75dB |

| Installed capacity | 50-100kW/set |

Features:

Δ Whole mixing process management and control, monitoring,recording,realized remote monitoring and after-sales support,imporoved management level.

Δ By the integral calculation and logic control of parameters of time, temperature, energy, rotation speed and pressure etc, an optimized rubber mixing is realized.

Δ Using high resolution sensors and weighing display instruments, the weighing accuracy is very high.

Δ All key elements and components are imported or from joint venture company famous products, with stability and reliability realized

Δ Open Chinese-English interface,enables the functions of multi-area display, monitoring and control for the system running process, easy and simple operation

Δ The field bus working system (i.E.setup of PLC substations) gives lower energy consumption.

Δ Automatically tests the running conditions, gives out alarm location and prompts solutions as abnormalities occur, facilitating maintenance and service, there are safety interlocking measures ensuring safety and security.

Δ Optimized dust removal and recovery system design, makes good environment free of dust flying and leakage and free of raw material waste.

Δ Within the system, its mixing engineering information managing system integrates the most modern information technology with the production management and the mixing process.

Δ For different structures of factory buildings (3,4-story buildings) and process layout, a system design is made with flexible solution.

Q:Why use the system?

A:This system is based and inspired by advanced technologies from Germany and Britain and is introduced by our company.Our R & D department has independently developed Automatic Batching System that include conveying,storage, weighing, batching and feeding system for materials in the form of powders, pellets, bulk materials, liquids, etc., which used in rubber, cable polymer materials, silicone, friction materials, plastics and other industries.This system can be compatible with various types of banbury mixer / kneader mixer / high-speed mixer.It is mainly composed of five sections:Powder, Oil, Bulk material, Dust removal and fully control system.Among that, the full-process management and control system combines the latest information

Technology with production management and process management, integrates the whole production process control, production plan management, material management, quality tracking management, and truly achieves the integration of management and control;It plays an important role in improving management level, product quality, and maintaining product stability.After years of continuous technological innovation and improvement, the system has been widely used domestically and internationally, and has been appreciated by customers.

Q:What is our purpose of service?

A:Machtech always adheres to the customer-centricity, followed the business philosophy of "integrity, win-win and innovation", with the goal of "creating high-quality products" and the purpose of "customer satisfaction" to provide each customer with a cost-effective technical solution.The series of products have achieved mutual combination of standard and non-standard design.Through the perfect technical management system, quality assurance and customer service system, the comprehensive quality and service of products have reached the international level.

Q:Why choose us?

A:MachTech, founded in 1996, specializes in providing "Industry 4.0" overall solutions of software and equipment integration for manufacturing enterprises.It is a national high-tech enterprise that develops and manufactures intelligent and environmentally friendly automatic batching systems, intelligent three-dimensional warehouses, intelligent logistics delivery systems, information management and control software, green and environmentally friendly equipment.Headquartered in Zhongguancun Science and Technology Park, Haidian, Beijing, it has a professional team of "experienced, skilled, realistic and innovative" of 220 people, including more than 80 technical talents in R&D and design.MachTech has two production bases in Tianjin Baodi and Zhuozhou and 5 offices located in Hebei, Jiangsu, Guangdong, Chongqing, and Fujian.Over the years, we have been engaged in the research and development, manufacturing, installation, commissioning, training, sales and service of related products.As of 2019, it has 45 patents, 32 software copyrights, and 5 independent trademarks.We have passed ISO9001:2015 quality management system, ISO14001:2015 environmental management system, and SGS-CE international safety system certification.MachTech is council member of "National Rubber and Plastic Machinery Information Center", "China Rubber Industry Association", "China Friction and Seal Association" and "China Warehousing and Transportation Association".

By the end of 2019, 1470 sets of intelligent automatic batching equipment, 77 sets of MES system have been sold to 506 domestic and foreign customers.Domestic market share:More than 75% of rubber products, more than 80% of conveyor belt, 90% of rubber used for railway, more than 70% of engineering rubber, more than 95% of plastic runways, and more than 75% of cable polymer materials.The market covers more than 20 provinces and cities, and the products are exported to Russia, Turkey, Croatia, Chile, Vietnam, Thailand, India, Myanmar, Iran, North Korea, Indonesia, Malaysia, Sri Lanka, South Korea and other countries.MachTech is a supplier of "Belt and Road Initiative" , key projects like "China-Laos Railway" and "Yawan Railway" track conveyor line;The first domestic high-speed iron powder metallurgy brake pad production line and the synthetic brake shoe production line of railway freight carriages have been developed and manufactured in China.

>>

Facttory Paper straw production line processing plant spiral paper core tube maker making machine

>>

Flat and Durable TPE Layer Eco-Friendly High Quality Yoga Mat for Fitness

>>

SMT Camera strobe lamp used in Fuji chip mounter XPF XP141 XP142 XP143 XP241 XP242 XP243 DEEM5391 DEEM5392 DEEM5464 DEEM5463 SMT pare parts

>>

New Arrival Men′s Stylish Padded Jacket with Snap Closure and High Collar, Cropped Puffer Jacket Full Zip Quilted Jackets for Men

>>

Cup Powder Coating Unit

>>

180*200cm 72*80 Inch XPE Foam Baby Crawl Play Mat Non-Toxic BPA Free Reversible Cartoon Design Kids Infant Playmat with Wholesale to Amazon

>>

Billiard table home club commercial marble countertop Chinese black eight American automatic ball collection standard type

>>

Advanced Fiber Laser Machines for Superior Marking and Engraving Quality

>>

New Arrival Skmei 1642 Men Digital Watch Custom Logo OEM Brand Stainless Steel Strap Waterproof 3ATM

>>

Factory Design 4-30m Length Hoist Lifting Machine Ladder Lift Mini Electric Hoist Lift

>>

Galvanized Sheet Metal Roofing Gi Corrugated Steel Sheet Zinc Roofing Sheet Iron Roofing Sheet

>>

SMD-500 Model Crushing Capacity 700-1200kg/Hr Low Noise Plastic Crusher

>>

Rear Right Control Arm For BMW G30 G38 G31 525i 530i 540i 31106861178 LEMFORDER 3981701/39817 01 OE 3110 6861 178

>>

Eco-Friendly Hot Sale Popular A4 10 Tab Bright Colour Pressboard Index

>>

5 Gallon PC Bottle Making Machine

>>

Squeezer Machine for Open Fabric and Tubular Fabric After Dyeing Machine

>>

ABS FR VRLA Solar Batteries Housings 2V GFM-200Cah

>>

2022 EID New Creation Crystal Gift Package Set Luxury Jewelry Box Baby Shower Giveaways

>>

Laser Cutting Machine Fully Automatic CNC Stainless Steel Aluminum Carbon Steel Fiber Single Platform Industrial Use

>>

High Quality Fitness Weight Lifting Grip Gym Gloves For Workout Men Protection Palm Cross Training Gloves