|

US$30,000.00-33,000.00

|

1 Set

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Molding Method

Extrusion Molding

Standard

European Standard

Application Scenarion

Brick Factory

Dimensions

Based on on-Site Inspection

Factory Span

Based on on-Site Inspection

Payment Term

Tt or as Negotiation

Technical Support

Supported

Design Drawings

Supported

Transport Package

Support Land and Sea Transport

Specification

50/50 60/60 70/75 90 120

Production Capacity

200000 Pieces Per Day

Product Description

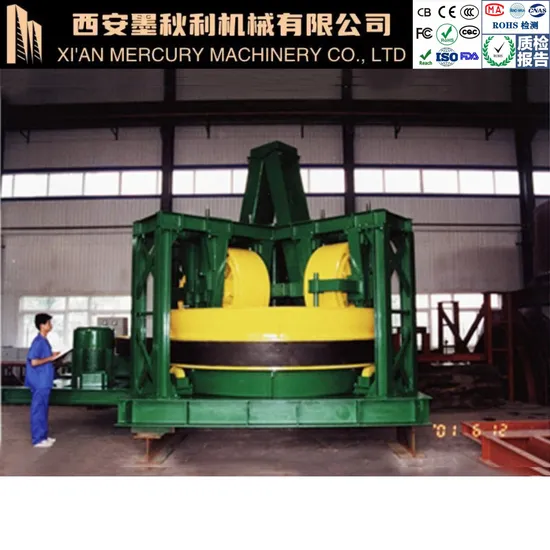

china High-Quality brick making machine Tunnel Kiln for brick production machine price Xian Mercury High-capacity foam concrete block machine for brick factory with lightweight block production.

Product Description

Tunnel kiln is computer-controlled, continuously operating kilns. Pushers move the train of cars non-stop at the predetermined rate. This method is ideal for all ceramics industries which require high volume production or the continuous production process. Computer technology allows kiln car move through the kiln to be controlled for changes in firing curves and firing temperatures. This increases the product recovery and minimizes production disruptions. Automation controls can be programmed to make firing changes for different product. Product Parameters

Technical Parameters

| Model | 3.6 Meter (inner width) |

| Output (standard pcs/day) | 70000-100000 |

| Brick size | 254*115*70mm |

| Firing Cycle (h) | 35-45 |

| Firing pass(%) | 95 |

| Suitable for the products | Suitable for good quality solid bricks & hollow bricks or any kinds of Facing Bricks (high hollow ratio) |

| Coal feeding method | Both automatic and manual is ok |

| Height for dried brick stacking (layer) | 14 layers |

| Automatic Level | High automation level, equipped with fully automatic loading & unloading system |

PRODUCT FEATURE

1. Computer control:

Tunnel Kiln is completely controlled by computer, include the car moving speed, firing temperature, etc. Through the control of all details, we can make sure the firing quality. Also it can reduce the labor cost.

2. Big capacity and land-saving.

The brick setting on Kiln car can be 14 layers high which increase the loading capacity. Compared with Hoffman kiln, is also occupy less land.

3. Well-distribution of temperature, low energy consumption of product, environment friendly.

Tunnel kiln is very burning efficient, which not only save fuel cost, but also product less pollution. So, tunnel kiln is also environment friendly solution.

4. Uniformed color, good appearance, high strength. Wide adoption of decoration bricks and insulation blocks.

The well-control of temperature makes sure of the high and suitable firing temperature, which can produce good looking as well as high strength bricks.

Company Profile

Company Information

Xi'an Mercury Machinery Co. , Ltd. is specialized in the brick industry for the whole project design, kiln design, project construction and management etc.. it is one of Xi'an High Tech Enterprises.It starts to explore international market from 2007, and build many brick production lines in Bangladesh, India, Pakistan, Brazil, South Africa, Mozambique, Mexico, Russia, Venezuela,Kazakhstan, Vietnam and other countries. It has been gained many high reputations from customer and partners and constructer. We devotes ourselves to business philosophy of the Pursuit of the Excellent Chinese manufacturing Brand, establish brand awareness and serve awareness among our staff, and provide an one-stop service to customer. We not only produce brick&tile making machine,but also major in and turn-key project forproviding solutions to brick & tile making industry .

After Sales Service

Our Services

brick production line.

Our service:

1.We majors in the abroad & home fired-brick designing, kiln designing, factory building designing and turn-key project.

2.We have many professional specialists, among which 6 are professor-level engineer and 10 are of high title.

3.We have accomplished over 50 brick projects of engineering, trading, technical support in Asia, Africa and South American countries.

4.We have also successfully constructed over 20 production lines in China.

Before-sale services:

(1) Tell customer how to build a brick plant, the complete plant including three parts, brick shaping machinery, drying and firing.(Confirm clay,power electricity,water,land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) site inspection

(4) We are responsible for the offer, flow chart, and detail specification of each machinery.

In-Sale services:

(1)Quality control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

After-sale services:

(1) We will send the technicians to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for machinery, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier. Warranty shall cover manufacturing defect in material and workmanship but exclude:

1. Daily wear and tear

2.mishandling or improper operation

3. Incoming power supply fluctuation

4. Consumable and spare parts.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication.

FAQ

1. what's the raw material for producing bricks?

Answer: clay,mud,gangue,shale etc.

2. how much land area for building a new brick plant?

Answer: it need above 20,000 square meters,the land area relate with capacity

3. when you need our proposal and quotation,what you have to mention in your inquiry.

Answer:please provide daily capacity,the brick size and you want to build a new brick plant or brick making machingery only. so we can give the proposal and offer accordingly.

4. what's the Trade terms?

Answer: it can be EXW,FOB,CIF,CNF,FCA,CPT, CIP

>>

Original Evolis Primacy 2 Duplex Dual Sided Plastic PVC ID Card Printer

>>

Chinese factory supplied hollow round carbon fiber tubes with 3K twill weave

>>

Portable Pump Flexible Screw Conveyor Rice Wheat Grain Powder Suction Machine

>>

MGF-2025 2hp electric portable air compressor mini air compressor made in china

>>

K&B creative minimalist ceramic woman body vase women body shape art flower vase

>>

Agricultural High Precision Machine Land Level Laser Shovel GPS Land Leveler

>>

Cement bulk machine Ash silo bottom fixed bulk machine Mineral powder stone powder bulk machine

>>

6NF9 Ricemill Combined Rice Mill Machinery 10 HP

>>

Galvanized Workshop Building Steel Structure Warehouse Storage Prefabricated House

>>

Factory Supply Automatic Tree Debarking Machine / Wood Peeling Machine

>>

Welldone Hot Sale T Shape Full Servo Automatic Baby Diaper Machine

>>

Carbon Steel Longitudinal Seam Metal Pipe Production Line

>>

Yonthin Cheap Price Smart Computer Double 2 Head Cap T Shirt Logo Embroidery Machine Computerized for Home Use

>>

Efficient and High Efficiency Four Edge Plywood Trimming Cutting Saw Machine for Plywood

>>

Apartment Decorate Arches Villa Entrance Iron Glass Main Door Grill Design

>>

Chinese shine skin / snow white GWS pumpkin seeds kernels Grade top

>>

Convenient Feeding Bb Fertilizer Blender Compost Mixer Turner Machine Automatic Mixer Stirrer

>>

Fashion hand plastic bath shower storage Portable bathroom PP bath storage basket with handle

>>

Black Powder 100% Water Soluble Best Potassium Humate Organic Fertilizer/ High Humic Acid 55-70%

>>

diamond hole expanded metal lath wall plaster mesh product