|

US$23,500.00-28,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Type

Tool Milling Machine

Milling Cutter Type

Vertical Milling Cutter

Automatic Grade

Automatic

Distance From Spindle End Fave to Table

120-820 mm

Worktable Size

600*1200 mm

Spindle Speed

8000rpm(Standard)/10K/12K/15K(Optional)

Air Supply Pressure Bar

6~8 Kg/Cm2

Transport Package

Wooden Case

Specification

2720*3350mm

Production Capacity

300set/Year

Product Description

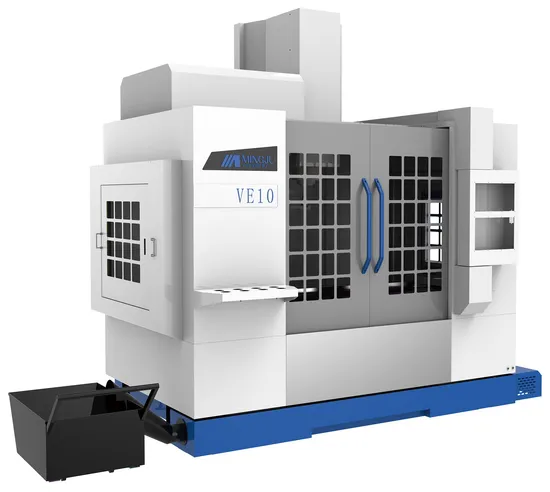

MINGJU VE10 Universal Vertical Machining Center

Product Parameters

| Item | Specification | Unit | VE10XP |

| Processing Range | X/Y/Z Axis | mm | 1100/600/700 |

| Distance from Spindle End Fave to Table | mm | 120-820 |

| Distance from Spindle Center to Column Guide Surface | mm | 650 |

| Table | Table Size | mm | 600x1200 |

| Max. Worktable Load | kg | 800 |

| T-Slot | mm/mm/mm | 5-18-110 |

| Spindle | Drive Type | - | Synchronous Belt Drive/Direct Drive |

| Spindle Speed | rpm | 8K/10K |

| Spindle Motor Power | kw | 15-18.5 |

| Spindle Taper | type | BT50 |

| Servo Axis | Rapid movement for X, Y, and Z axis | m/min | 36/36/30 |

| The cutting feed rate | mm/min | 1-10000 |

| Tool Magazine | Tool Magazine Type | - | Arm-Type Tool Magazine |

| Tool Holder Specification | type | BT-50 |

| Tool Capacity | tools | 24 |

| Maximum Tool Diameter | mm | φ105 |

| Maximum Tool Diameter (No Adjacent Tool) | mm | φ200 |

| Maximum Tool Length | mm | 350 |

| Maximum Tool Weight | Kg | 15 |

| Tool Change Time (Tool-to-Tool) | Sec | 7 |

| Main Accuracy | Positioning Accuracy | mm | ±0.005 |

| Repeat Accuracy | mm | ±0.003 |

| Others | Machine Weight (Including Water Tank) | ton | 7 |

| Length/Width/Height (Including Water Tank) | mm | 3000x2500x2900 |

| Air Supply Pressure | kg/cm2 | 6~8 |

Product Description

Bed, Column And Saddle

The bed, column, and saddle are composed of Meehanite HT300 grade cast iron, which includes very high dampening characteristics. The one piece bed casting and column are stress relieved to ensure machine geometry is maintained throughout the life. Wide spacing of the linear guideways ensures optimal support for the table and saddle in full travel of each axis. Heavily ribbed castings provide superior dampening for high speed machining and aggressive milling. The mating surfaces of all critical contact points including the column, linear bearing blocks, linear guideways, and table surfaces are fully ground to optimize fit and accuracy.

Guide ways

The X, Y, & Z-axis are standard with heavy-duty 45mm linear guideways. All the guideways are placed against ground shoulders to maximize rigidity and geometry.

Spindle

The permanently greased spindle bearings require no maintenance. The 8,000 rpm spindle is driven by a (7.5/11kW) AC servo motor. 15,000 rpm spindle is an option,upgrade toVE10IL. The four 70mm ceramic spindle bearings help with the concern of thermal growth on the 15,000 rpm spindle.

Ball Screws And Axis Drives

Each axis is driven using a high precision, fully ground ball screw. All the ball screws are supported on using angular contact thrust bearings and are perfectly centered between the linear guideways. The 40mm ball screws are driven directly using direct-coupled AC servo type drive motors eliminating vibration, noise, and backlash.

Fully Enclosed Machine Enclosure

The machine enclosure is made of heavy duty sheet metal to contain the chips and coolant. The entire machine is fully enclosed. The removable side doors allow direct access to the inside of the machine. The front door opening (40") allows for easily loading and unloading of work pieces.

Flood Coolant System

A dedicated flood pump provides high volume coolant to the machine tool. The coolant enters the head casting and exits through the bottom of the spindle to help control thermal growth. The mounted nozzles are fully adjustable to accommodate various tool lengths. The 200 L coolant tank provides adequate capacity for any application.

Lubrication

Automatic lubrication is provided to the linear guideways and ball screws via way oil. Oil is delivered by metered valves, which precisely control the volume. A low-level alarm on the CNC warns the user preventing possible damage to the guideways and ball screws.

Company Profile

>>

Hygiene Equipment Elder Nursing Care Pad Underpad Manufacturing Machine

>>

GB/T32.1 Coarse Thread Hex Head Bolts With Wire Holes Locking

>>

Kitchen Cabinet Modern Luxury Solid Wood

>>

Hot-Melt Coating Composite Machine for OPP Tape/Masking Tape/Kraft Paper/Double Sided Tape

>>

0.90mm 0.95mm 1.0mm Wollen Ball Badminton Multifilament Strimgs 11mtr for Indian Market

>>

9HP/13.5HP/15HP Gasoline Engine Mini Excavator Loader Tractor Mounted Pto ATV Small Towable Digger Backhoe with Best Price

>>

Ultrasonic electronic deratization

>>

Magnesium Ingots 1gr-10kg 99.9% Metal Element 12 Pure Ingots

>>

Hot sale electric RC toy car 1:18 remote control climbing toy motorcycle car green color RC climb motorcycle toy car for kids car gift 666-281B

>>

Top Quality Paraffin Wax Bulk In Order Supply Customized Packaging Fully Refined Paraffin Wax For Sale

>>

NHE ODA-1780-2K Built-in type automatic telephone

>>

Flexible PCB Board FPCB Assembly Manufacturer Printed Circuit Board for Drones Applications

>>

Air fryer Fully automatic large capacity electric fryer for household use

>>

Accept custom logo philippine 25kg 50kg plastic waterproof transparent pp woven rice fertilizer sack of rice price 50 kg

>>

Universal Radial Drilling Machine Z3040X14 Hydraulic Metal Drill Machine Price

>>

Radiator Hose OE 2045012582 FOR MERCEDES BENZ

>>

Brass Gold 3W 5W 7W 8W 3000K 4000K 6000K Ra 80 Indoor COB LED Ceiling Track Fixture Lamp for Corridor Aisle Porch

>>

Ultimate Hydration Hyaluronate Acid Facial Mask for Glowing Skin

>>

Elegant Silk Jacquard Bow Tie for Business Men

>>

160HP 4WD Farm Tractor