|

US$1.00-80,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Process Usage

CNC Metal Turning-Milling Processing

Movement Method

Linear Control

Control Method

Semi-Closed Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE, RoHS, ISO 9001

Max Machining Diameter

32mm

Control System

Fanuc, Simens, Mitsubishi, Syntec, Hcn Optional

Spindle 2

Mechanical Spindle

Transport Package

Wooden Package

Specification

TC32 SERIES

Production Capacity

1000PCS/Year

Product Description

Product Description

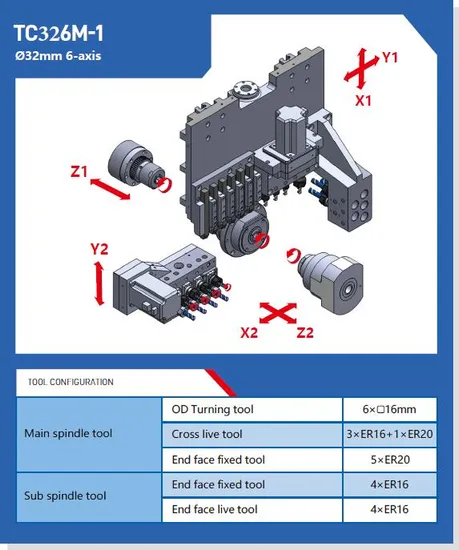

Model: TC326M

System available: FANUC, SIEMENS, MITSUBISHI, SYNTEC, HCN etc.

Double spindle

6-axis function

Max machining diameter: 32mm

Mechanical spindle

Features

*Each axis equipped with imported high-precision linear guide,ball screws and precise bearings. * Using synchronous guide bush structure,realize high-speed and high-precision machining. * With guide bush or without guide bush switching flexiblely to meet different needs of processing. * Key components with gas sealing structure, oil and slag prevention, improving service life and stability. * Select high torque motor, high rigidity and high strength slipway for each axis and tool holder to meet the requirements of large cutting volume and high efficiency. * High scalability, tool quantities matched with different requirements of processing, reaching great cost-effective.

* Available with ER20 tools to increase the machining range. Layout

Case study

Product Parameters

| Model | | TC326M-1 | TC326M-2 | TC326M-3 | TC326M-4 |

| | | 6-axis,dual spindle | 6-axis,dual spindle | 6-axis,dual spindle | 6-axis,dual spindle |

| NC system | | SYNTEC 220TB | SYNTEC 220TB | SYNTEC 220TB | SYNTEC 220TB |

| Lathe rated power | kw | 16 | 16 | 16 | 16 |

| Machining range |

| Maximum machining diameter | mm | φ32 | φ32 | φ32 | φ32 |

| Maximum machining length (one-time clamping)With guide bush | mm | 310 | 310 | 310 | 310 |

| Maximum machining length (one-timeclamping)Non guide bush | mm | 2D | 2D | 2D | 2D |

| Main spindle power | kw | 4.4 | 4.4 | 4.4 | 4.4 |

| Sub spindle power | kw | 3 | 3 | 3 | 3 |

| Main spindle max through hole dia | mm | φ33 | φ33 | φ33 | φ33 |

| Main/sub spindle rev speed | rpm | 6000/6000 | 6000/6000 | 6000/6000 | 6000/6000 |

| Sub spindle max clamping dia | mm | φ32 | φ32 | φ32 | φ32 |

| Sub spindle max through hole dia | mm | φ33 | φ33 | φ33 | φ33 |

| Max tool installed qty | | 23 | 24 | 25 | 26 |

| OD Turning tool |

| Qty x Model | mm | 6*φ16 | 6*φ16 | 6*φ16 | 6*φ16 |

| Cross live tool |

| Cross live tool | mm | 3*ER16+1*ER20 | 3*ER16+1*ER20 | 3*ER16+1*ER20 | 3*ER16+1*ER20 |

| Drilling dia | mm | φ13 | φ13 | φ13 | φ13 |

| Tapping/Threading die dia | mm | M8 | M8 | M8 | M8 |

| Live tool rev speed | rpm | 5500 | 5500 | 5500 | 5500 |

| Live tool power | kw | 1 | 1 | 1 | 1 |

| End -face tool (Main spindle) |

| Fixed | Qty x Model | mm | 5*ER20 | 5*ER20 | 4*ER20 | 4*ER20 |

| Drilling dia | mm | φ13 | φ13 | φ13 | φ13 |

| Tapping/Threading die dia | mm | M10 | M10 | M10 | M10 |

| Live | Qty x Model | mm | -- | -- | 3*ER16 | 3*ER16 |

| Drilling dia | mm | -- | -- | φ10 | φ10 |

| Tapping/Threading die dia | | -- | -- | M6 | M6 |

| Live tool rev speed | mm | -- | -- | 5500 | 5500 |

| Live tool power | kw | -- | -- | 0.75 | 0.75 |

| Back end-face tool (Sub spindle) |

| Fixed | Qty x Model | mm | 4*ER16 | 4*ER16 | 4*ER16 | 4*ER16 |

| Drilling dia | mm | φ10 | φ10 | φ10 | φ10 |

| Tapping/Threading die dia | mm | M8 | M8 | M8 | M8 |

| nd face live tool | mm | 4*ER16 | 3*ER16 | 4*ER16 | 3*ER16 |

| Side- Live tool | mm | -- | 2*ER16 | -- | 2*ER16 |

| Drilling dia | mm | φ10 | φ10 | φ10 | φ10 |

| Tapping/Threading die dia | mm | M6 | M6 | M6 | M6 |

| Live tool rev speed | mm | 5500 | 5500 | 5500 | 5500 |

| Live tool power | kw | 0.75 | 0.75 | 0.75 | 0.75 |

| Rapid feed speed | m/min | 18(X1/Y2)

24(X2/Y1/Z1/Z2) | 18(X1/Y2)

24(X2/Y1/Z1/Z2) | 18(X1/Y2)

24(X2/Y1/Z1/Z2) | 18(X1/Y2)

24(X2/Y1/Z1/Z2) |

| Feed motor power | kw | 1 | 1 | 1 | 1 |

| The power capacity | kva | 16 | 16 | 16 | 16 |

| Air pressure device | mpa | 0.6 | 0.6 | 0.6 | 0.6 |

| Weight | kg | 3700 | 3700 | 3700 | 3700 |

| Dimensions | mm | 2550*1500*1900 | 2550*1500*1900 | 2550*1500*1900 | 2550*1500*1900 |

Customer visiting

Our Advantages

1.High quality/Reliable/Robust machines

2.Service and support are top priorities

3.Quickly response 7/24

4.Customized Machine According to Customer's Requirements

5.Integrated solution provider

6.More details please contact us, or send your drawings for professional recommendations

Service

Service and support are a top priority. Our engineers and after sales team are trained to provide uncompromising customer service and support.

Training policy

Pre-training is available at our factory freely for our clients, video or remote training can also be provided. We charge for local training on the basis of travel expense + man day.

Warranty policy

Warranty period: 12-month. It is free of charge if it is damaged under normal use during warranty period. If the equipment is damaged due to improper operation, we charge material fees within one year. After one year, it will charge material fees and Labor costs

Company Profile

FAQ

1.What's the main products of your company?A: We specialized in Swiss-type CNC lathes for small, complex, precision metal parts processing.2.What CNC system do you use?

A:FANUC, SIEMENS, MITSUBISHI, SYNTEC, HCN .It depends on your choice.

3.How can I choose the most suitable machines?A:Send us the products drawings and applications ,we will choose the most suitable machines for you.

4.What is your leading time?A:Generally speaking, 1-3 month based on different quantity.

5.What's the Payment Terms?A: Our practice is T/T ,30% deposite ,70% balance before shipment.

6.What's the shipment Terms?A: By sea, by train, by truck, by air(metal parts samples).

7.What's the offering Terms?A:EXW/Shenzhen, FOB/Shenzhen, CIF/Shenzhen, CFR/shenzhen.

8.Where is your factory located? How can I visit there?A :Our company is located at Building A#, Xinhui industrial park, Tangtou, Shiyan, Baoan, Shenzhen, Guangdong, CN. We are warmly welcomed to visit us.

>>

Foundry Carbon Cup Copper/Steel Melting Pot Clay/Silicon Carbide Sic Graphite Crucible

>>

Factory Price Upgraded Multi-Function Wireless Horn Light Type-C Bicycle Light

>>

Czz Power Window Regulator Lifter W/ Motor for Honda CRV Re2/Re4 2011-07 Rr 72710-Swa A01, 748-163, 72710-Swa-A01 Supplier Auto Parts Manufacturer

>>

Automatic Horizontal Injection Molding Machine

>>

Yogurt Milk Bottle Blow Molding Machine Automatic Extrusion HDPE PP

>>

Whole body bio scan health analyz for help screening early disease equipment

>>

Low Price Concrete Jbt30 Jbt40 Concrete Drum Mixer Concrete Cement Pump

>>

Water soluble heat shrink film Shrinkable wrapping film shrink film

>>

ESD Turnstile ESD Flap barrier for ESD sensitive area

>>

Hot Selling Edible Food Grade Vegetable Carbon Black Carbon Powder

>>

Sodium Pyrosulfite Supplier with Best Prices for Mining Chemicals

>>

HC-I040C-1 Cheap price PIPE INSPECTION CAMERA Full HD 1080p

>>

Animal Feed Pellet Making Machine Poultry Feed Pellet Making Machine

>>

Knitted Beanie Warm Hat Winter Hat outdoor Cap Warm Cap

>>

Tc540 Top Quality 3/4/5 Axis CNC Milling Machine CNC Lathe and CNC Cutting Machine Center

>>

LLDPE Towable 45qt Cooler with Pull Rod and Wheel for Outdoor Camping Fishing

>>

CY1-12-5 CY2-12-5 Life boat battery chargers Input voltage AC 42V Max output voltage DC 14.5*2

>>

Split King Folding Electric Adjustable Bed with Memory Foam Mattress

>>

ASTM D256/ISO179/ISO180 Automatic Plastic Sample Notcher

>>

Mylar Film Wrapping Machine for Sandwich Busbar with Easy Operation