|

US$150,000.00-200,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Placing Form of Template

Horizontal

Die Cutting Tool

Wooden Mold

Computerized

Computerized

Automatic Grade

Automatic

Application

Paper Packaging Materials

Transport Package

Waterproof Wooden Package

Specification

950*540mm; 1100*650m; 1200*650mm

Production Capacity

15set/Month

Product Description

The product video in YOUTUBE: https://youtu.be/fLfhfrTy0xo

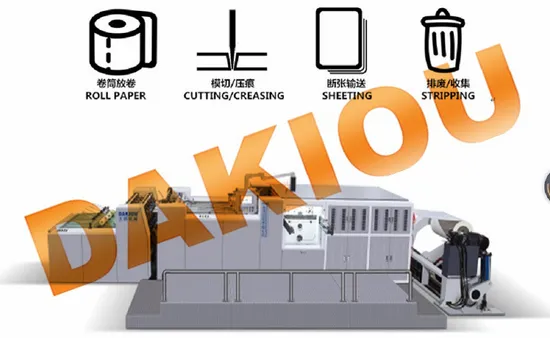

High Speed Automatic Die Cutting and Embossing Machine with Full Stripping unit

The machine is used for die cutting, creasing, embossing and full stripping coherently. It is an ideal machine for producing paper cup fan, paper box, envelop, medical box, post-pressing packaging, etc.

Easy and Safety Operation, High Efficiency!

Technical S[ecification

| Type | PY-950S | PY-1100S | PY-1200S |

| Precision: | ± 0.10mm | ± 0.10mm | ± 0.10mm |

| Capacity | 90-140/times/min | 90-120/times/min | 90-12/times/min |

| Max cutting size: | 950 x540mm

Or 950 x640mm

| 1100 x650mm

| 1200 x650mm

|

| Max feeding Width: | 950mm | 1100mm | 1200mm |

| Suitable Material: | 100-600g/m2

Pe coated paper, cardboard paper, Kraft paper etc | 100-600g/m2

Pe coated paper, cardboard paper, Kraft paper etc | 100-600g/m2

Pe coated paper, cardboard paper, Kraft paper etc |

| Maximum Pressure: | 250T | 250T | 250T |

| Total Power: | 25KW | 25KW | 28KW |

| Weight: | 13T | 15T | 15T |

| Overall Dimension: | 10000 x 4000 x 2000 mm | 10200 x 4150 x 2000 mm | 10200 x 4150 x 2000 mm |

| Working Air Source: | Air pressure 0.5-0.7Mpa | Air pressure 0.5-0.7Mpa | Air pressure 0.5-0.7Mpa |

Main Features:

1. The normal working speed is 90-120times/min. Paper rolling, cutting, sheeting, and stripping all in one

2. It is driven by imported servo motor, and the imported color sensor recognizition is used. With pinheads to strip the scrap, the maichine collects stack auomatically.

3. With the shaftless unwinding unit in the front part, as well as the pneumatic brake and multilevel tension controller, in order to control the process of roll paper unwinding.

4. To ensure the machine steady and strong work, we develop the worm and gear system, lubricated oil recyling system, alarming system,lubrication blocking alarming and feeding blocking arlarming system, and limit alarming and stripping failed alrming system.

5. Use PLC as control center, in coordination with the original LG electrical elements from KOREA, original Panasonic sensor from JAPAN, original SHARO and MINGMAN pneumatic parts, to ensure that machines are high-quality.

If you have any question, please contact with me.

>>

YY Australia standard AS2047 Aluminium sliding door

>>

Outdoor Multifunction Walking Stick Trekking Poles Telescopic Fold Crutches Hiking Stick Crutch Elderly Metal Stick Walking Cane

>>

High Precision Check Weigher Machine with Rejector

>>

Wholesale Outdoor Home Furniture Event Natural Timber Wedding Party Banquet Garden Fabric Dining Chair for Restaurant Hotel

>>

High quality 1005 Flower Shape BPA Free Silicone Mousse Cake Mold

>>

Haijia New Model Double Nozzle Water Jet Loom with Good Service

>>

6 Burners Lotus Flame European Style Free Standing Gas Hob Kitchen Stove

>>

High Temperature Resistance Adhesive PVC Tape

>>

50MM Mechanical Throttle body For ATV(all terrain vehicle) 500CC Engine with map Sensor, TPS Sensor 35999 & idle motor IAC 26179

>>

High Quality Thermal Break Aluminum Triple Glazed Glass Big 3 by 4 Slide Windows in Jamaica Sliding Windows

>>

Clubmax Laser Light Show Projectors 15W 20W 30W 40W IP65 Waterproof Outdoor Animation Laser Light

>>

China-Russia High-Tech Products Warehouse Service

>>

NEMA AC Premium Efficiency C Flange Motor with UL and CSA

>>

Custom Made Good Quality PVC Plastic Product Plastic Part Cattle Foot Ring

>>

Table tennis racket set

>>

Vmc850 Metal Milling Machine 3 Axis 5 Axis Vertical Machining Center

>>

Top sale 2021 hifu laser /cartridgeless hifu /hifu 22500

>>

Yinaier standard online composite bubble envelope bag making machine MCXDLLDJ-1000

>>

JINNFA CNC High Precision Metal CNC Lathe Machine

>>

Yuchai Ycr405e Rotary Drilling Rig