|

US$0.10-10.00

|

1,000 Pieces

(MOQ)

|

Basic Info.

Model NO.

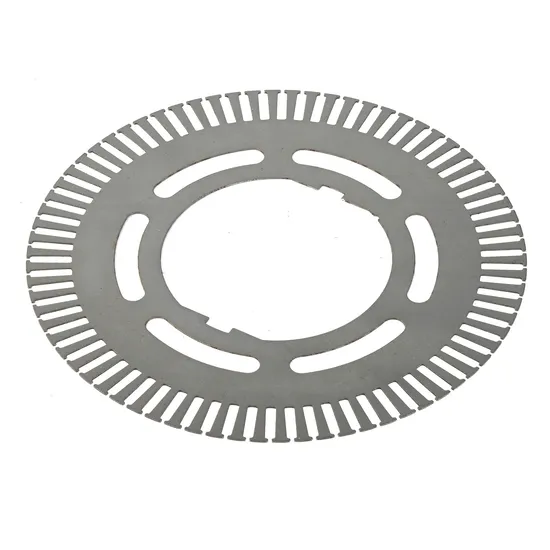

Customizable motor laminations

Processing Type

Stamping Part

Mould

Multistep Progressive Dies

Surface Processing

Coating

Industry

Metal Stamping Parts

Processing Form 1

Interlocking

Processing Form 2

Backlock

Production Capacity

1000000pieces/Year

Product Description

Hot-sale Customizable motor stator iron Core laminations

| Metal process | stamping, laser cutting, glue-bonding, punching, welding, riveting, turning, rotating, die casting, coil winding, injection molding,

copper welding, slitting, core assembly |

| Material | stainless steel, silicon steel, aluminum, alloy |

| Surface finish | coating ,electrophoresis (20μm) |

| Service | excellent after-sales service |

| Tolerance | +/-0.02 to +/-0.05. |

| Inspection | IQC, IPQC, FQC, QA. |

| Quality control | IATF 16949 |

Our Advantages: 1. 40 years of Professional Sheet metal service. 2. Facing overseas markets, most of our products are exported

3. We are competitive by High Quality, Low Cost, and quick Delivery.

4. We have a skilled & powerful technical department.

5. We have advanced equipment that can meet any requirements for all kinds of motor iron core processing

6. OEM/ODM, Customized service.

See below for a detailed company profile...

Company profile:

Established in 1986, Yuyao Yuanzhong Motor Punching Co., Ltd. is a professional manufacturer and exporter who is concerned with the design, development, and production of motor iron cores, currently manufacturing stator and motor laminations of around 100,000 pieces per month.

We are located in Ningbo, Zhejiang, with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world. Our customized products are widely used in high-efficiency and ultra-high-efficiency motors, servo motors, elevator traction motors, shield motors, and new energy motors, etc.

Covering an area of 20,000 square meters, our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction.

We have 110 employees and are equipped with 11 high-speed stamping presses including Japan AIDA200T, AIDA125T, and Taiwan INGYU80T, and 6 aluminum die-casting machines ranging from 45 to 280 tones. We are also able to provide additional services with equipment such as slitting lines, precision surface grinders, and a welding robot. 40 ordinary stamping presses with a capacity ranging from 5 to 10 tons would fulfill your simple needs.

We have passed IATF 16949:2016 Quality Management System since 2022.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

FAQ:Q1: Are you a trading company or manufacturer?A: We are the manufacturer.Q2: Do you supply customized services? A: Yes, we supply customized services. Q3: Are the pictures the same as the real products? A: Yes, but the picture only shows some of our samples, if you have more sizes or special size design requirements, please contact us for details.Q4: Do you provide samples? A: Yes, we can offer samples.Q5: How about the price range?A: We provide quotations of our products based on the real-time market price of raw materials, exchange rate, and the need for precision. Please send us your inquiries including the drawings, your desired material No., your monthly demand, and molding type (i.e., progressive die or simple die).

We reply as soon as possible, at the latest within 24 hours.Q6: What shipping method can I choose? A: Samples can be delivered by DHL or air transportation.Q7: What is the delivery time? A: It depends on the order quantity, normally mold time for progressive die takes around 70 days.Q8: What's the payment way? A: Payment <= 1000 USD, 100% in advance.

Payment >= 1000 USD, 50% in advance, balance before shipment.If you have any questions, please do not hesitate to contact us!

>>

Greetmed High quality hospital adjustable electric bed

>>

Water Proof Disposable Plastic Pp Cpe Medical Boot Shoe Covers Disposable Non Slip

>>

Windproof Sunshade Slats Aluminum Shutter Window

>>

Vacuum Sealer Machine Food Meat Fruit Vegetable Vacuum Packing Paper Packaging Material

>>

High Voltage Power Line Lightning Protection Suspension Type 10kv Polymer Insulator

>>

For AUDI Auto Engine Timing Chain Tensioner Car Engine 06E109217A 06E109217H TN1505-2

>>

2021 Shangtao The New Yarn Guide Textile Ceramic

>>

Colorful children indoor plastic slide and swing playground toys equipment for sale

>>

Interior Decoration Aluminum Expanded Metal Mesh for Ceiling Tiles

>>

Diamond Saw Blade Granite Marble Cutting Disc Porcelain Tile Ceramic Blades

>>

Eco Friendly Household Product Air Freshener Spray 250ml Aerosol Car Air Freshener

>>

Portable Extendable Platform Self-Propelled Electric Hydraulic Scissor Lift for Construction

>>

Wholesale Souvenir Gift Magnetic Logo Sticker Custom Fridge Magnet

>>

163-6002 Retaining Pin for Brunswick Bowling Machine

>>

Cheapest 5.72 Inch Android 12 Octa-Core 4+64GB Handheld Computer NFC Fingerprint Rugged Hand Terminal Mobile 2D Barcode Scanner

>>

Whole body testing instrument Non-invasive and radiationless health analyzer machine

>>

OEM Disposable Mob Caps Clip Cap Bouffant Cap Hair Net Head Cover

>>

Lab Size Electrical Heating Vacuum Kneader (sigma mixer) for Ink, Silicone Rubber, CMC

>>

New Massager Trainer Smart Music Boxing Machine Wall Target with Low Price

>>

Hotsales License Frame Document Certificates Degree Graduation Diploma Frame License Plate Frame