Basic Info.

Spinning Method

Ring Spinning

Processing Material

Cotton

Certification

CE, ISO9001: 2000

Customized

Non-Customized

Automatic Unwinding, Lap Changing

with

Pressure(PA)

0.6*1000000-0.8*1000000

Compressed Air Demanded(Nm3/H)

2.8

Lap Transport

Lap Trolley, Lap Transport Suction

Noil Extraction

Central Suction+Return Integral Suction

Product Description

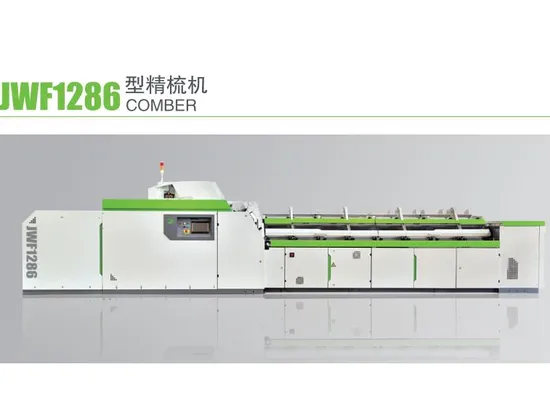

JINGWEI Brand model JWF1286 Combing Machine using for high quality ring spinning textile machine line

24h Online Customer Service

Product Description

JWF1286 Combing machine are suitable for combing process to produce combed slivers with straight, parallel andevenness fibers. The laps from the lap former will be combed by the machine to remove short fibers ,neps and impurities. Thecombed slivers can be used for spinning high quality ,medium and fine yarn, This machine is advanced and reliable, withimproved performance indexes, a better nep removing performance, automatic unwinding, lap changing and piecing-upfunctions, can run up to an maximum speed of 500 n/m, It is the first-class combing machine in China at present.

Details Showing

1- Max speed can reach 500 nips/min and production up to 80kg /h.

2- Use computer for dynamic analysis, optimize detaching rollers and cylinder transmission design.

3- Ensure combing and lapping quality of the web during high-speed combing. Optimize movement coordination, timing, positioning design of nippers, detaching rollers, cylinders, etc.

4- Optimize the drafting system, using three-up and three-own curve drafting attached with a pressure gauge drafting deviceand main drafting and pre-drafting distances adjustable.

5- Use the integrated air duct design. Eliminate the impact ofhigh-speed and large cotton suction air stream on detaching andlapping of webs at high speed.

6- Set the process parameters on the touch screen digitally: provide touch screen troubleshooting feature and failure remotediagnostic capability.

7- With 90° ,110°,130° three types cylinder combing technology

8- Reduce the number of changes of silver cans, increase work efficiency substantially

9- 600mm or 1000mm diameter sliver cans are optional according to customer requirement.

10- Automatic unwinding,lap changing and piecing-up functions.

JWF1286 WITH 1000mm CAN FOUNDATION PLAN

Product Parameters

| Speed(nips/min) | 500 |

| Production(kg/h) | 80 |

| Installed Power(kW) | 7.25 |

| Combing Surface Angle | 90, 110, 130 |

| Automaticunwinding,lap changing andpiecing-up function | With |

| Lap weight(g/m) | 60-80 |

| Lap Max Diameter (mm) | 550 |

| Width(mm) | 300 |

| Sliver Counts(ktex) | 3-6 |

| Pressure(Pa) | 0.6*106-0.8*106 |

| Compressed air demanded (Nm'/h) | 2.8 |

| Can Diameter(mm) | 600/1000 |

| Can Height(mm) | 1200 |

| Lap Transport | Lap Transport Suction, Lap Trolley |

| Noil Extraction | Central Suction+Return Integral Suction |

Company Profile

Qingdao Hongda Textile Machinery Co., Ltd (here after referred to as QDHD)is the subsidiary company ofJingwei Textile Machinery Co. Ltd. It is a large-scale backbone enterprise of textile machinery manufacture,as well as an important manufacturing base for carding machinery and auto-winder.

The Technology Center of QDHD is certified as the National Technology Center. Blowing-Cardingmachinery wins the First-Class Scientific and Technological Progress Award issued by China Textile IndustryAssociation and is the promotion program in The Ninth Five-Year Plan of the State Science and TechnologyCommission. The three leading products of QDHD-Carding Machine, Blowing-Carding Machine and Auto-winder, have all passed the ISO9001 quality system authentication, winning QDHD the honor of "PioneerEnterprise of National Quality Control".

Facing the new situation, Qingdao Hongda Textile Machinery Co. Ltd will be committed to continuouscontribution to the development of Chinese textile machinery, the technological progress of the Chinesetextile industry and the improvement of its international competitiveness by executing new initiatives andadvancing with times.

>>

Roasted Peanut Flour New Premium Products Peanut Protein

>>

General tools MAN32/40 MAN3240 MAN L32/40 MAN L3240 MAN V32/40 MAN V3240

>>

Multi-Functional Gym Black Yoga Pilates Stick Bar Adjustable Pilates Resistance Band Bar

>>

Latest Multi Functional Customized Home Goods Small Rectangular Iron Metal Wire Basket

>>

High Shear Homogenizing Vacuum Emulsifying Mixer Cosmetic Homogenizer Mixer

>>

Bread Style LED Outdoor Wall Lights (12W)

>>

20mm-110mm Glassfiber PPR Pipe Making Machine/PPR Pipe Production Line/PPR Tube Machine

>>

Micro Universal Filter Tips Pipette Biorad Davinchi Human GmbH Elisys Fully Auto Enzyme Immunoassay Analyzer 300UL 1100UL Sterile Plastic Pipette Tips

>>

High Capacity Impact Crusher (PF-1214)

>>

Full Automatic Diaposable Sanitary Napkin Pad Making Machine

>>

Heavy-duty Auto baler Eco-Friendly

>>

Massage Adjustable Bed Frame with Head Tilt and Lumbar Support

>>

Maximum Working Speed 50mm/S Opening Height 430mm Fully Servo Electrical Press Brake

>>

CPVC PVC Plastic ASTM D2846 Water Supply Pipe/Tube Joint Fitting

>>

2.8" Vine Smart Wi-Fi Thermostat

>>

High Quality European Technology Plywood Production Line for Sales to Inida

>>

Vmc855 3 Axis / 4 Axis Vertical Machining Center

>>

100/130 Micron 4 Inch H Type Disc Filter for Agricultural Drip Irrigation System

>>

wholesale waterproof safety rain cpe pvc pp blue disposable pe plastic shoe cover protective foot cover

>>

Squeeze Rubber Green Color for Screen Printing