Basic Info.

Type

Tool Milling Machine

Milling Cutter Type

Angle Milling Cutter

Milling Cutter Structure

Indexable Type

Controlling Mode

Artificial

Automatic Grade

Automatic

Certification

CE, ISO 9001

Transport Package

Wooden Frame or Wooden Box

Specification

2000*1800*2500mm

Production Capacity

100PCS/Month

Product Description

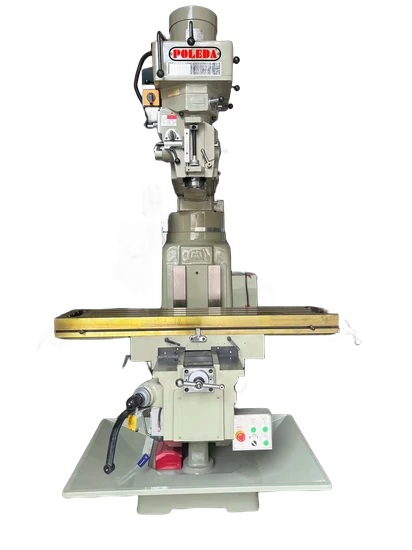

Discover the unparalleled precision of our 5M Vertical Metal Turret Milling Machine. As the leading name in China for universal milling solutions, we pride ourselves on continuous improvement and unmatched professionalism. There is no best, only better. Introducing the cutting-edge 5M Vertical Metal Turret Milling Machine, designed for exceptional performance and reliability.

As the most professional manufacturer in China, our universal milling machines set the industry standard for excellence.

Our philosophy: There is no best, only better. We constantly strive to enhance our products to meet your evolving needs.

Product Description

Product Parameters

Product introduction

The turret milling machine, also known as a rocker arm milling machine, rocker arm milling, or universal milling machine, boasts a compact structure and small size, making it highly flexible. The milling head is capable of rotating 90 degrees, both front and back rotations at 45 degrees, while the rocker arm is extendable and can rotate 360 degrees on the horizontal plane, significantly enhancing the machine's effective working range.

Build Quality

Crafted from high-grade cast iron, the body of the universal radial milling machine promises high precision and longevity following artificial aging treatment. The lifting platform features rectangular guide rails with multiple contact surfaces and rigid feet. Undergoing high-frequency treatment and fine grinding, the slide is plastinated to ensure superior motion accuracy and durability. The spindle, made of chrome-molybdenum alloy, is equipped with precision angular contact bearings, and has been tempered and finely ground to provide powerful cutting force and exceptional accuracy.

Usage

A turret milling machine is a versatile, lightweight metal-cutting machine offering both vertical and horizontal milling capabilities. It is ideal for milling the flat, inclined, groove, and spline surfaces of medium and small parts. This machine finds extensive application in industries such as machining, mold making, instrumentation, and more.

Mechanical Characteristics of the Turret Milling Machine

The machine's casting is made of high-quality Mihanna cast iron, which provides excellent rigidity, stability, and resistance to deformation.

The main shaft is constructed from chrome-molybdenum alloy and undergoes tempering, heat treatment, and precise grinding, coupled with precision bearings, ensuring powerful cutting force and superior accuracy.

The milling head gearbox is made from cast iron, providing robust rigidity, minimal deformation, and increased weight for precise cutting and enhanced durability.

The screw cap on the three-axis screw is crafted from advanced phosphorus bronze, offering exceptional wear resistance and an extended service life.

After high-wave heat treatment, the XY-axis slide demonstrates outstanding wear resistance, enhancing its service life. The XY-axis interface features an imported wear-resistant plate, which ensures easy operation, minimal wear, and long-term durability.

Equipped with a state-of-the-art lubrication system to uniformly distribute oil points, ensuring smooth slide operation.

This machine is 100 kg heavier than similar products, offering additional stability and robustness.

Featuring a powerful 5hp motor and a high-rigidity, precision NT40 spindle, this machine is perfectly suited for large parts and heavy-duty cutting tasks.

| Product Name | Milling machine |

| Product model | 5M/5S/5HG |

| Product technical parameters | |

| dimension | Table size | 1370*305MM |

journey | Left and right stroke(X) | 800MM |

| Front and rear stroke(Y) | 380MM |

| Up and down stroke(Z) | 380MM |

| Arm reach | 600MM |

| Distance from spindle end face to table surface | 100-480MM

|

| Table bearing | 350KG |

Principal axis coefficient | Spindle taper | NT40 |

| Spindle speed | 80-5440RPM(16-speed) |

| Spindle travel | 127MM |

| Spindle horse power | 5HP |

| Milling head | Milling head tilt Angle | 45° front and back |

| Lead screw | X/Y/Z-axis screw diameter | Tr32/Tr32/Tr35MM |

| Three-axis lead screw pitch | 5MM |

| Machine size (L * W * H)(MM) | 1750*1700*2200MM |

| Approximate machine weight | 1580kgs |

| disposition | Accessories name | quantity |

Standard parts for machine tools | 1,Hand oil pump | 1 |

| 2,Work light | 1 |

| 3,Organ board + protective glue | 1 |

| 4,Lever | 1 |

| 5,Tools and toolboxes | 1 |

| 6,Operating instruction | 1 |

Detailed Photos

Our Advantages

Certifications

FAQ

FAQ

1.What is the MOQ for your production?

A.The MOQ depends on your requirements for color, logo and so on.For some normal items, we have in stock, the MOQ is 1 set.

2.How to control the quality of the products?

A.We have always placed great emphasis on the quality level is maintained.Moreover,the principle we always maintain is "to providecustomers better quality, better price,and better service".

3.What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Machine, Lathe Machine , Milling Machine,Grinding Machine ,Vertical Machining Center ,DrillingMachine ,Radial Drilling Machine ,Sawing Machine and so on .

4. What is your trade terms?

A :Ex-works FOB, CFR and CIF all acceptable.

5.What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

6.What CNC system do you use?

A:FANUC, SIEMENS, MITSUBISHI, SYNTEC, HCN .It depends on your choice.

7.How can I choose the most suitable machines?

A:Send us the products drawings and applications ,we will choose the most suitable machines for you.

8.what kind of package do you offer?

A.Normally in plywood case, to make sure all goods in good condition. Customized package can be acceptable.

9.Can your plant do OEM?

A:Yes it is no problem. We can do OEM and ODM for any customers 10.How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for mac

>>

Condensation Cure Silicone Middle Hardness RTV 2 Liquid Silicone

>>

Jh2702 Transformer Single/Three Phase Manufacturing Portable Turns Ratio Meter TTR Tester

>>

3 Watts 5 Watts Face Mask UV Mini Laser Machine Marker

>>

Flotation Wheel Rim Harvester Wheel Spreader Wheel Steel Rim

>>

Removing Iron Magnetic Articles Self-unloading Separator MC12 Series

>>

high efficiency waste fibers cotton fiber wool opening machine

>>

200ton High-Precision Double-Pump Full-Automatic Front-Style 3rt Hydraulic Molding Machine for Making Silicon Rubber Products

>>

110kVA 50Hz 400V Hot Sell Open Frame Diesel Generator Set

>>

23-24 Manchester United United Second Away Football Shirt No. 7 Mount Fans' Short Sleeve T-shirt Football Shirt Male

>>

PVC Duct Cable Management Trunking, , Resistance Trampling Cable Concealer Trunks

>>

Integrated Steel Scanner Touch Screen Integrated Steel Bar Detector Concrete Rebar Scanner Locator

>>

Hot sales damascus hunting camping knife with antler handle black ox horn handle

>>

99.999% Purity Argon Gas for Industrial Use

>>

PVC TPO Membrane/Roofing Welding Machine Hot Air Stationary Welder

>>

Alloy Structural Steel 35CrMoA Round Steel 4135 Bar

>>

Outomatic Lubrication Control Vertical Shaft Impact Crusher with Lubrication Circulation Cooling System for Mining and Construction Industry

>>

OEM/ODM Factory Affordable Customized Vacuum Fridge Freezer Forming Mould for Efficient Production

>>

Double-Ended Type-C Data Cable Suitable for Apple iPhone15iPad to PRO Dual Pd Fast Charging Tpyec Mobile Phone Car Laptop Dedicated Charger Cable

>>

Portablehousehold Home HEPA Filter Scent Diffuser Air Purifier

>>

1500mesh Ultrafine Micro Crystalline Silica Fillers Silica Quartz Powder