|

US$300,000.00-1,000,000.00

|

1 set

(MOQ)

|

Basic Info.

Product Type

Particle Board Making Machine

Automatic Grade

Semiautomatic

Screw Design

Double-Screw

Machine Included

The Full Complete Production Line

End Product

Particle Board

Particle Board Size

4*8feet or Customized

Particle Board Plant

100-300m3 /Per Day

Machine Color

Be Customized

Production Capacity

10 Sets /Year

Product Description

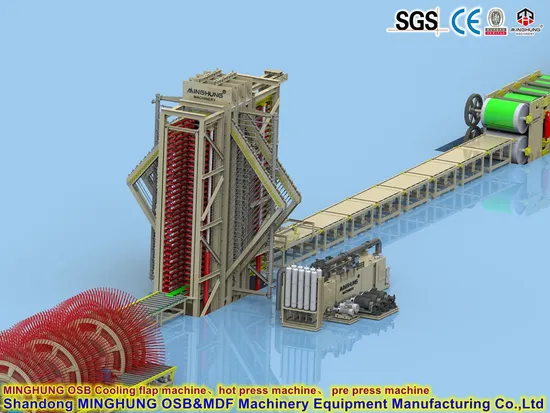

Factory Direct Supply Woodworking Machinery OSB Particleboard Production Line Equipment

01:PRODUCT DESCRIPTION

OSB board

OSB board is belongs to particleboard. During the molding of the particleboard, the upper and lower surfaces of the oriented particleboard arrange the mixed rubber particleboard in the direction of its fiber, while the core layer particleboard is arranged horizontally to form a three-layer structural board embryo, and then the oriented particleboard is made by hot pressing.

The shape of this particleboard requires a relatively large length and width, and the thickness is slightly thicker than that of ordinary particleboard. Directional paving methods include mechanical orientation and electrostatic orientation. The former is suitable for large shavings oriented paving, while the latter is suitable for small shavings oriented paving. The directional paving of particleboard makes it have the characteristics of high strength in a certain direction, and it is often used instead of plywood as structural materials.

02:FULL PRODUCT PARAMETERS

<1> Drum Chipper

|

| Inlet size | 240*750mm(H*W) |

| Blade quantity | 2pcs |

| Knife roll diameter | 800mm |

| Power | 132kw |

<2> Ring Chipper

|

| Wood strands thickness | 0.4-1.0mm |

| Capacity | 5000-8000kg/h |

| Knife length | 449mm |

| Power | 250kw |

<3> Triple Pass Drying Machine

|

| Cpacity | 10000kg/h |

| Original moisture | ≤80% |

| End moisture | 2% |

| Power | 440kw |

<4> Vibrating screen

|

| Screening cloth | 2 |

| Screening area | 12 m2 |

| Screening capacity | 70m3/h |

| Power | 11kw |

<5> Gluing

|

| Capacity | 500m3 /per day |

<6> Forming machine

|

| Surface forming machine | 2 sets |

| Capacity | 2 *45m3/h |

| Core forming machine | 1 sets |

| Capacity | 65m3/h |

| Forming width | 1300mm |

| Forming thickness | 30-120mm |

<7> Continuous press

|

| Convey speed | 10-30m/min |

| Working height | 1250mm |

| Belt width | 1500mm |

| Power | 75kw |

<7> Hot press

|

| Pressure | 1200 ton |

| Hot plate size | 2650*1680*120mm |

| Layers | 22 |

| Heating medium | Oil |

| Heating temperature | ≤180ºC |

| Closing time | 10s |

<8> Sanding machine

| |

| Max sanding width | 1300mm |

| Sanding thickness | 3-50mm |

| Sanding belt size | 1350*2800mm |

For this production line, it can produce 100000m3 one year.

And we can produced as your capacity requires

03:PRODUCT DETAILS

Rotary drum dryer, for drying the wet wood strands/shavings, because their original moisture is high, it is not suitable for making particleboard, therefore, after be dryed by drum dryer, their end moisture will be about 2%, it is suitable and good for making particle board.

Glue blender, For spreading glue on wood strands, seperately spreading glue on surface strands and core strands

Mat forming machine, for spreading glue on wood strands, seperately spreading glue on surface strands and core strands

Continuous pre press machine, for pre pressing the particle board and make it be forming, also discharge inside air.

Multi opening hot press machine, for pressing the particleboard be in required thickness and be solid and strong.

04:PACKAGING&SHIPPING

05:WHY CHOOSE US

1. With many years production experience, we can ensure each osb board machine be suitable, good and strong

2. With advanced production equipment and technology, ensure the whole osb making machine production process fluently, good and correct.

3. With experienced workers, engineers, technicians, to design, improve our machine

4. Insist use good material, parts and accessories, ensure our machine good quality and long life span

5. With good after sales service, make sure you will get quickly response anytime when you meet questions

05: AFTER SALES SERVICE

<1> Machine Installation:

We can send engineers go to install machine, degue, and teach your workers

<2> Warranty:

1 year

<3> Factory layout:

After machine production start, we can make factory layout for you

<4> If meet problem when operation machine

Contact us at the first time, our engineers will help check and solve quickly

Welcome contact us for more information if you are interested

>>

5SHX0660F0002 3BHE022333R0101/GVC713A101

>>

Braves Jerseys 13 Ronald Acuna Jr Baseball Jerseys MLB

>>

Horizontal and Vertical Drilling Milling Machine (ZX6350ZA)

>>

9000L Per Hour Craft Beer Yeast Deparator Disc Stack Centrifuge with Flow Meter

>>

Potato Sweet Potato Four-Wheel 2wheel Walking Farm Tractor Household Carrot Digging Sweet Potato Harvester

>>

T3 Series Residential Water Meter Ultrasonic Water Metering Ultrasonic Water Flow Sensor

>>

Kipardo New Design 18" 6X139.7 4X4 off Road Alloy Wheel Car Rims

>>

Commercial Layer Chicken Cage Animal Cage for Poultry Farms

>>

Mini Tractor 12 - 18HP Compact Tractor Small Tractor Farm Agricultural Use

>>

Good Walking All Day Running Inner Soles Comfortable Inserts Latex Foot Sport Insole for Comfort

>>

Good Performance 30~45kw Automatic Single Ridge Double Rows Crop Potato Planter

>>

Multi functional sculpting beauty equipment/slimming device/shaping device explosive fat slimming machine/fat dissolving slimming machine

>>

Winter Heatinq Vest USB Standing Collar Intelligent Electric Heating Clothing for Adult

>>

HC-M129 Aluminium Adjustable Shower Stool Bench Bath Chair For Elderly and Disabled

>>

HM60 5V Electronic handwheel pulse generator CNC wheel encoder rotary pulse generator

>>

High Quality Wicker Rattan Storage Basket for Kitchen 4 compartments Cosmetic Storage Tray Wholesale Supplier

>>

Lab Equipment Manufacturers Steaming Shrinkage Tester

>>

Revolutionize Grain & Oil Processing with Our High-Performance Embryo Rolling Machinef6080

>>

clay pug mill vacuum ceramik for clay

>>

Factory Supply Halal & Kosher Brazilian Berry Powder