|

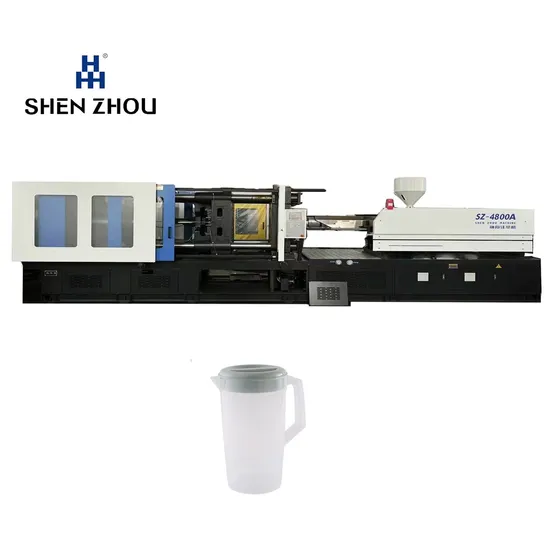

US$21,500.00-23,000.00

|

1 Set

(MOQ)

|

Basic Info.

Plastic Type

Thermoplastic

Plasticizing Way

Screw Type

Clamping Way

Hydraulic & Mechanical

Computerized

Computerized

Certification

CE, ISO9001:2008

Function

Multifunctional Plastic Products Making

Motor

Servo Energy Saving

Advantages

Energy Efficient,Long Service Life

Operation Language

Multilingual, You Can Choose

Experience

20 Years of Rich Experience

Quality

Professional Quality Control Team

After Sale

Product Lifetime Maintenance

Brand

Shenzhou,China Certified Brand

Service

One-Stop Complete Solution

Export Experience

More Than 15 Years

Transport Package

Standard Export Wooden Box

Specification

8.4× 2.2× 2.6m

Origin

Suzhou, Jiangsu, China

Production Capacity

50sets Per Month

Product Description

Product Description

Product Paramenters

| ITEM | UNIT | SZ-3000A |

| INJECTION UNIT | | |

| SCREW DIAMETER | mm | 60 | 65 | 70 |

| SCREW LID RATIO | L/D | 22.7 | 21 | 19.5 |

| THEORETICAL SHOT VOLUME | CM3 | 848 | 995 | 1154 |

| SHOT WEIGHT(PS) | g | 772 | 905 | 1050 |

| INJECTION PRESSURE | Mpa | 207 | 176 | 152 |

| THEORETICAL INJECTION RATE(PS) | g/s | 241 | 283 | 328 |

| PLASTICISING CAPACITY | g/s | 35.2 | 43.3 | 51.8 |

| SCREW TORQUE | N.m | 2530 |

| MAX.SCREW ROTATE SPEED | r/min | 150 |

| INJECTION STROKE | mm | 300 |

| CLAMPING UNIT | |

| MAX.CLAMPING FORCE K | KN | 3000 |

| MAX.OPENING STROKE | mm | 590 |

| SPACE BETWEEN TIE BARS | mm | 610×610 |

| MOULD HEIGHT | mm | 220-630 |

| MAX.DAYLIGHT | mm | 1220 |

| EJECTOR FORCE | KN | 70.6 |

| EJECTOR STROKE | mm | 150 |

| EJECTOR QUANTITY | | 9 |

| OTHER | |

| PUMP MOTOR POWER | KW | 30 |

| PUMP PRESSURE | Mpa | 16 |

| HEATING POWER | KW | 22 |

| HEATING ZONE | | 5 |

| SIZE | m | 6.7×1.75×2.25 |

| NET WEIGHT | t | 11 |

| OIL TANK CAPACITY | L | 560 |

| INTERNATIONAL DESIGNATION | | 3000-1750 |

New type 5-point toggle device of stable movement curve,gentle shock. Superior mould platen to ensure no out of shape if high-pressure clamping.

Hard chrome plated high tensile strength tie bars made of superior alloy.

Wear-resistant guide for moving platen.

Transducer control clamping stroke.

Many step control for speed and pressure of clamping and opening.

Eiection device offer dwell,single,more, vibration function.

Low pressure mould protection function.

Hydraulic mould height adjustment with roungh and fine operation.

Mechanical and electrical dual safety interlock.

Automatic centralized lubrication system with far pressure detector.

Proportional pressure and flow control with fine adjustment and precision. Know-how manifold design,compact,reasonable and fast respond.

Imported world famous hydraulic valves.

Imported world famous hydraulic sealing rings.

Imported technology hydraulic hose and fittings.

Low noise hydraulic system.

Precision oil filter and oil cooler.

Nitrided screw and barrel with long service life. Smelted screw with big L/D ratio with good plasticizing and color-fixing.

Double injection cylinder of compact construction and good equilibrant.

Transducer control injection stroke.

The speed of low speed and large torque hydraulic motor can be adjusted.

Screw back pressure control and nozzle anti-leakage control movable hopper for easy remove material.

Injection-catriage can be used for slacking,re-feedingor fixed-feeding.

Speed and pressure of injecting and holding controlled by time or position.

Equipped with reverse device to be easily removed and cleaned.

Why Choose Us

1. 20 years of professional injection molding machine and mold manufacturer, excellent quality, honest management

2. Continuous technological innovation, optimized product structure, longer service life

3. Lifetime maintenance of the product, 24 hours after-sales service

4. The main components are all world-renowned brands

5. Dedicated quality control department

6.Ex-factory price

Company Profile

SHENZHOU-Your trusted plastic processing partner Our company - injection molding machine, blow molding machine, main blower, mold, computer embroidery machine professional manufacturer - located in the national new port city of Zhangjiagang City, Xizhang Town, close to the Yanjiang Expressway and 204 National Road, close to Shanghai, Nanjing, Suzhou, Wuxi Large and medium-sized cities such as Nantong have convenient transportation.

The company has accumulated rich experience in manufacturing injection molding machines for many years, high standard design and precision processing, using imported famous brand hydraulic, electrical and sealing components, and fully creating SZ series automatic computer injection molding machine and peripheral supporting equipment, with its excellent quality and stability. The performance, superior price performance ratio, to the greatest extent to meet the interests and needs of customers.

Packing & Delivery

We will apply lubricating oil and spray anti-rust agent to the products before shipment, prepare enough spare parts, and confirm that they are fully fixed before shipment. We pay attention to details and hope to bring you a better experience.

FAQ

1.Q:Are you a factory or trading company?

A: Industry and Trade Integration, we supply the factory price with good quality, welcome to visit !

2.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end and we have a dedicated quality control department.

3.Q:What are your normal lead times?

A:Our company typical lead times range from 25-35days after receipt of order.We also have independent venues and engineers to deal with more urgent orders, which can be shipped within 2 weeks.

4.Q:About the price?

A:We will estimate the cost and provide you with the best price. We can guarantee you the best product quality and after-sales service at the same price. Old customers will enjoy more price concessions.

5.Q:How is your machine different from other businesses?

A:We have optimized the overall layout of each part of the machine to make the machine run smoothly and have a longer service life. The fine parts have exclusive marks, which makes it more convenient for customers to replace parts and use.

6.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Shenzhou Machinery, No. 22 Zhenbei Road, Fenghuang Town, Zhangjiagang City China. All our clients,from home or abroad, are warmly welcome to visit us!

You are welcome to send us samples, we will customize high-quality machines for you! Best wishes for you

>>

2023 original brand new apple watch series 7 original brand new

>>

Shouxiang 600D Aluminum Tube 4 Bow Bimini Top Boat Cover Boat Canopy Bimini Tops for Boats

>>

Automatic Transfer Switch for Generator ATS Panel Changeover 63A/100A/125A/160A 3p 4p ABB Socomec Available China Genset Controller Supplier

>>

852753MIC10 UTERS Replace MAHLE Hydraulic Filter element

>>

Quiet Operation Electric Drive Resort Transfer Golf Instruction Electric Go Cart Electric Golf Cart

>>

New Type Fuel Diesel Oil Water Solid Three Phase Industrial Disc Centrifuge Separator

>>

63 Ton 1600 2500mm Length Kcn Electro Hydraulic Synchronous CNC Mini Press Brake Machine Sheet Plate Small Bending Machine

>>

EVA White Foam Tape

>>

Titanium Alloy Exhaust Downpipe Modified for Ferrari 458 488 F430 SC Auto Replacement Modification Electronic Valve whatsapp008613189999301

>>

HAWKER 48V 11PZB825 MOTIVE POWER BATTERY

>>

Flash and Fire Point Test on Bitumen/civil engineer Supplier

>>

Anodized factory supply aluminum perforated metal sheet

>>

GSM outdoor antenna parabolic wifi antennas with SMA connector 2G+3G+4G 9dBi 3G

>>

Johnson Type Filter Screen Nozzle

>>

Factory Price Good Quality Complete Cold Passenger Cars Tyre Retreading Machines Tire Retreading Machines OTR Tyre Retreading Machine

>>

Other exterior accessories various golden dragon bus models 5-0041 led bus headlight for sale

>>

3 ply non medical civil face mask mascarilla 3 piegues certificadas with shield face

>>

Byloo Retractable Sea Fishing Rod 2.1m 2.7m 4.5m Carbon Fiber Casting Fly Fishing Rods Canne A Peche Connecting Strong Saltwater

>>

New Type 102HP World Rice Wheat Combine Harvester for Best Price

>>

Aluminum Alloy Rings Automatic CNC Radial and Axial Ring Rolling Forging Machine