|

US$28,500.00-182,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Automatic Grade

Automatic

Certification

GS, CE, ISO 9001

Control System

Fanuc, Siemens, Mitsubishi

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

3500*2110*2100

Production Capacity

1000/Year

Product Description

Product Description

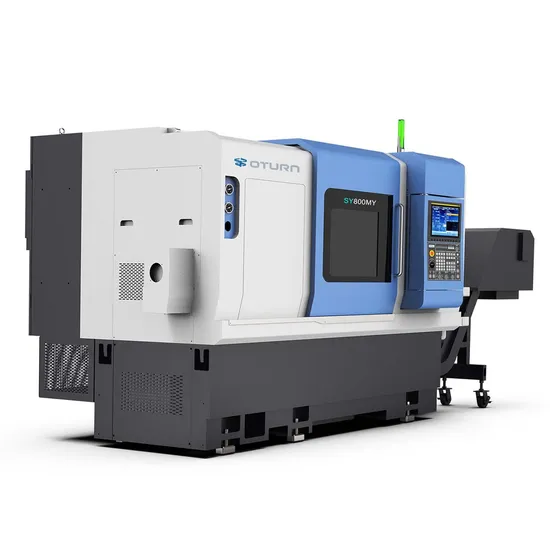

The two-axis lathe offers simultaneous processing of both workpiece ends in one clamping, significantly streamlining manual operations, increasing output, and reducing processes. The secondary spindle ensures complete turning and seamless workpiece transfer during machining, thereby minimizing cycle times. Featuring a 30-degree inclined design, this machine excels in precision, robustness, and cutting stability. Constructed with high-strength HT300 cast iron using finite element analysis, the lathe bed's one-piece design ensures superior mechanical rigidity and long-term accuracy. This enhances processing stability and tool life, with stress relief treatment further boosting accuracy stability. The machine boasts a high-strength roller linear rail design and a screw pre-tension transmission system, amplifying rigidity performance. Its sleek and sophisticated appearance aligns with contemporary trends.

Main features of this machine tool:

1. Employs a direct drive synchronous electric spindle device featuring a magnetic ring incremental encoder (sine and cosine) with a positioning accuracy of 20 arc seconds and a C-axis indexing accuracy of 40 arc seconds. This setup effectively eliminates spindle vibration with a nose deflection accuracy within 0.002MM, enhancing workpiece surface finish. The rear-mounted rotor allows for quicker installation and maintenance, while the spindle motor's cooling system suppresses thermal displacement, ensuring a constant spindle temperature. Undergoing rigorous dynamic balance testing, the spindle system retains excellent accuracy, rigidity, and efficiency. It is adept at both finishing and rough machining, and heavy cutting, ideal for mass production of complex, high-smoothness products.

2. Features a high-rigidity integrated design servo power turret, supporting rapid and precise tool changing. Coupled with high-speed power axis milling, it provides outstanding turning and milling processing capabilities. Equipped with a high-rigidity BMT interface for the tool holder and driven by a servo spindle motor, the power transmission shaft ensures optimal performance.

3. Equipped with roller linear guides and precision-ground ball screws, this machine guarantees superior accuracy and durability. Each axis employs a direct transfer structure and a double-anchor pre-relay method, minimizing thermal displacement and greatly improving processing accuracy. High-rigidity, large-sized, heavy-duty linear slide rails maintain accuracy under impact, ensuring smooth, low-noise displacement and extending service life.

4. Offers a comprehensive hydraulic and lubrication system, featuring high-quality hydraulic pumps, valves, and other components, significantly reducing failure rates. The design of these systems prioritizes simplicity and reliability.

5. Integrates a Taiwan rotary chuck cylinder and an optional automatic chip removal device, significantly reducing operator labor intensity and facilitating safe, efficient production. These functional components are programmable and controllable, with various functions designed and installed according to user-specific requirements, including special fixtures.

Product Parameters

| Name | Unit | SY800MY/E |

| Max. swing diameter over bed | mm | Φ800 |

| Max. processing diameter | mm | Φ450 |

| Max. processing diameter on the tool holder | mm | Φ450 |

| Max. processing length | mm | 690 |

| Spindle nose | type | A2-6 |

| Max. spindle speed | rpm | 4300 |

| Oil cylinde/chuck | lnch | 8″ |

| Spindle bore diameter | mm | Φ66 |

| Bar diameter | mm | Φ52 |

| Spindle motor power | kw | 18/22kw |

| Spindle torque | N.m | 103-227 |

| X/Z/Y travel | mm | 280/780/100(±50) |

| X/Z/Y axis linear guide specification | spes | 45/45/35 roller |

| X/Z axis screw specification | mm | 4012 |

| X/Z/Y motor power | Kw | 2.9/2.9/1.8 |

| X/Z positioning accuracy | mm | ±0.005 |

| X/Z repeatability | mm | ±0.003 |

| X/Z axis moving fast | m/min | 24/24 |

| Power turret type | mm/pcs | BMT55-12T |

| Power turret power | Kw | 5.0/47.7 |

| Max. speed of power tool holder | rpm | 5000 |

| Outer diameter tool holder specification | mm | 25X25 |

| Inner diameter tool holder specification | mm | Φ40 |

| Adjacent tool change time | sec | 0.2 |

| Programmable hydraulic tailstock | / | Programmable |

| Max. stroke of tailstock | Mm | 530 |

| Sleeve diameter | mm | Φ100 |

| Sleeve travel | mm | 100 |

| Tailstock sleeve taper hole | type | Mohs 5# |

| Machine size | mm | 3500*2110*2100 |

| Machine weight | kg | 6800 |

| Cutting fluid tank volume | L | 250 |

| Cooling water pump power | w | 750 |

| Hydraulic unit box volume | L | 40 |

| Hydraulic pump motor power | kw | 1.5 |

| Lubricant tank volume | L | 2 |

| Automatic lubrication pump motor power | W | 50 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

>>

5m/5s Universal Vertical Rocker Turret Milling Machine

>>

K30 Dynamic Testing Plate Load Tester

>>

Multifunctional wheat/corn/soybean/Roo/Millet thresher and sheller machine

>>

High Speed Woodworking PVC Sealing Edge Bander Machine

>>

Custom Logo Embossed Whiskey Glass Set Personalized Engraved Color Bamboo Wooden Hip Flask

>>

High Quality Cookware External/Internal Grinding Machine

>>

Children Car Baby Swing Car Ks-34

>>

Mixer Smoothie Professional Electric Power Blender Table Heavy Duty Commercial Blender

>>

2 Cavities Automatic Pet Plastic Bottle Making Blowing Machine

>>

Universal RAM Knee-type DRO Milling Machine X6436

>>

grating drain plastic frp step grating grating plates grp

>>

ISO Approved Wood Chipper Manufacturer

>>

Kiddie indoor soft play area with trampoline park Indoor kids playground for shopping center

>>

Wall Panel Machine Lightweight Wall Panel Machine.

>>

Cat Veterinary Hospitalization Cage Stainless Steel Animal Clinic Cage

>>

Automatic PLA Pet Bottle Plastic Making Preform Injection Molding Moulding Machine

>>

Wholesale M8 32/64/128GB Wireless Video Game Console 3800 Games Gamepad for Android

>>

1100 H14 Aluminum Coil 1050 H14 Aluminium Coils

>>

KINGHOOD Beard Brush And Safety Razor Holder

>>

Lower Price Car Front Shock Absorber For Toyota Prius 2004 - 2009