Basic Info.

Model NO.

Liquid Distributor

Separation Mode

Mass Transfer and Separation Media

Operating Type

Continuous Type

Distillation Equipment Type

Steam Distillation Equipment

Transport Package

Plywood Boxes

Specification

Tailor made according to customer requirement

Production Capacity

100 Tons Per Month

Product Description

Product Description

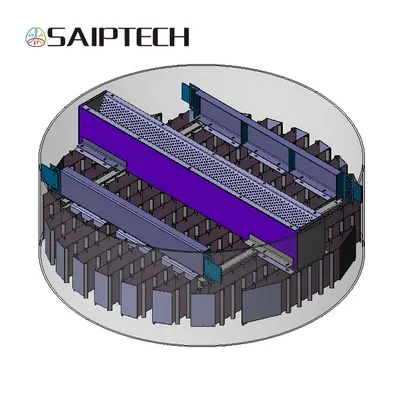

LIQUID DISTRIBUTOR

Other then packing, liquid distributors are probably the most important item in tower internals. Proper liquid distribution usually determines the successful operation of the tower and the performance failure of many packed towers stems from liquid distribution problems. In addition to providing a uniform liquid distribution pattern to the top of the packed bed, the distributor also must provide sufficient gas passage area to avoid a high pressure drop or liquid entrainment. The liquid distributor should have a flow range suitable for the service, and provide resistance to plugging, fouling, and foaming.

The selection of type of liquid distributor depends on:

• Liquid rate

• Fouling tendency

• Turndown ratio

• Nature of feed

A liquid distributor may be categorized as the following types:

| Type | Applications & Advantages | Examples |

Pressurized | • Pipe orifice distributor is suitable when

vapor velocity is high and 60-70% open area is required to avoid localized flooding.

• Spray nozzle distributor preferable for heat transfer applications.

• Low cost; simple construction; easy to support; and generally consumes less vertical space than most other distributors. | 1. Pipe Orifice Distributor

2. Spray (Nozzle) Distributor |

| Gravity | • The weir type distributor is better suited for the fouling applications and has excellent turndown, but it can usually provide only a limited number of drip points.

• The orifice type distributor can be designed with a large number of drip points to provide superior liquid distribution. | 1. Gravity Fed Pipe Orifice Distributor

Weir-Type Distributor:

2. V-Notched Trough Distributor

Orifice Distributors:

3. Riser Type Distributor

4. High Performance Trough Distributor

|

Company Profile

For many years, Saiptech has been a leader in engineering for mass transfer, phase separation, and reactor internals. Our innovative technology and patented high-performance products cater to a diverse clientele in industries such as petroleum, petrochemical, chemical, and environmental protection. We specialize in processes like distillation, rectification, absorption, desorption, and multiple phase separation.

Our commitment to continuous research and development, coupled with extensive engineering experience, enables us to provide comprehensive solutions to our clients. Our services encompass process simulation and optimization, de-bottlenecking, hydraulic calculation and analysis, field troubleshooting, CFD modeling, and on-site services. In our modern fabrication shop, we manufacture various equipment and components, including distillation trays, column packing, internals, and reactor internals.

We take pride in our professional and experienced staff, known for their expertise in technology, process design, equipment design, manufacturing, system integration, plant design, modifications, project management, and process consultancy. The Saiptech team, composed of seasoned chemical and mechanical engineers, consistently delivers design packages that surpass client expectations.

As a privately owned and operated company, Saiptech adheres to the core belief that clients come first. This principle has shaped our business model, emphasizing professionalism, trust, and a commitment to excellence. Our mantra of "Clients first" guides us in all our endeavors, ensuring a dedicated approach to serving the needs and achieving the goals of our valued clients.

>>

Most Popular Compact Excavator Free Shipping Mini Excavator Chinese Crawler Digger Earth Moving Machine Mini Excavator Small Digger

>>

China Manufacturer Supply Building Material Anti-Static Access Floor HPL Panel for Computer Room, Data Center

>>

Non-Slip Glazed Ceramic Indoorrustic Tile Bathroom Ideas for Wall Decoration

>>

Truck Loading Motorized Expanded Flexible Roller Conveyor Manufacturer Joinsun China UL CE

>>

Chengming Crafts Factory Wholesale Industrial Bookcases Bookshelf Home Office Furniture Corner Wooden Book Shelf Rack for Living Room

>>

Gaide Top Supplier Breshless Cordless Chainsaw with Two Battery

>>

High Quality Carbon Steel Chain Pipe Wrench

>>

Automatic Pick and Place Machine Carton Packing Machine Bottle Packer

>>

Transparent Glass Double Glow Wake-Up Led Light Digital Alarm Clock Radio Sunrise Wake Up Light Lamp

>>

Factory Price Two Person New Arrival Fishing Inflatable Kayak Drop Stitch Canoe

>>

Woodworking Wooden Door Lock Hole Milling Machine

>>

wholesale cheap exercise training muscle kneeling pad custom abdominal wheel ab fitness rollers

>>

Wholesale Private Label 9 Pearl Colors Duochrome Pigment Glitter Highlighter Makeup Eye Shadow Powder

>>

Automatic Multilayer PVC Tile Production Line, Lvt Floor Making Machine

>>

Sew on glass rhinestones in flat back stones triagnle shape

>>

Machine-Room-Less Panoramic Passenger Elevator /Observation Elevator

>>

Customized Stainless Steel Spiral Torsion Spring for Mouse Trap

>>

Hot Selling 2t 3m Electric Reach Stacker Stand-on Control Pallet Forklifts Truck

>>

Garlic Onion Sorting Machine Garlic Bulb Grading Machine Tomato Onion Grader

>>

New Design Zero Gravity Custom Made in China Factory Sale SL Track Body Massage Chair