Basic Info.

Surface Finish Process

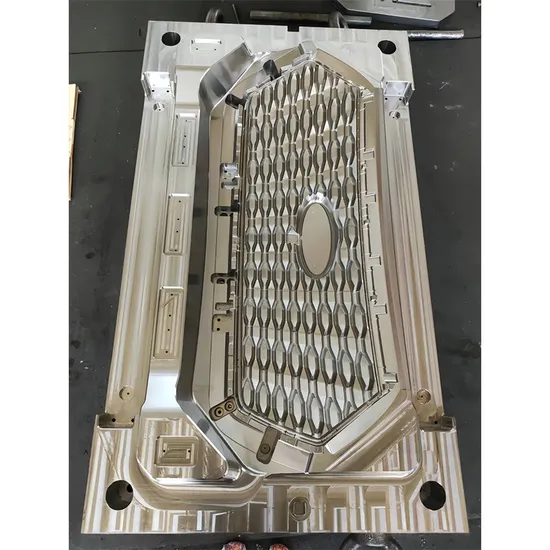

Polishing

Mould Cavity

Single Cavity

Process Combination Type

Compound Die

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Certification

TS16949, CE, ISO, FDA

After-sales Service

1years

Surface Finish

Polishing, Graining etc.

Mold Material

P20. 718, ,P20hh ,S136 etc.

Mold Life

300K~1000K Shots

Transport Package

Inner Packing

Product Description

As a premier custom plastic injection molding manufacturer, we specialize in bespoke plastic molding injection parts. Embrace eco-friendly practices with our recycled plastic injection molding solutions, tailored to meet your unique requirements.

etificates

| SGS, GB/T19001-2016/ISO9001:2015, Material Cert, etc.

|

Capabilities

| 3D printing, Mold Manufacturing, Injection Molding, etc.

|

Drawing, File Formats

| SolidWorks, Pro/Engineer, STP, IGS, STEP, AutoCAD(DWG, DXF), PDF, JPG, etc.

|

Machinable Tolerance

| ±0.005mm, 100% QC inspection before delivery, providing test report

|

Optional Material

| PA, PP, PC, PE, POM, PVC, PS, PMMA, PU, PEEK, ABS, ASA, TPR, etc.

|

Surface Treatment

| Powder Coating, Painting, Zinc/ Chrome/ Nickel Plating, PVD, Polishing, Brushing, Sand Blasting, Anodizing, Passivating, Rubber Coating, etc.

|

Logo, Color, Grain

| Customizable (Pantone Color Card, AI Vector Picture)

|

Quality Control

| CMM, Projector,Image Measurement Instrument, Tool Microscope, Marble Platform, Roughness Measurement, Hardness Tester, Salt Spray Tester, Micrometer, Automatic Height Gauge, Go-No Go Fixed Gauge, Micrometer, Vernier Caliper, etc.

|

Package

| Wooden Pallet/ Wooden Case/ Carton/ Foam Box With Bubble wrap/ Plastic Bag/ Plastic Film/ Pearl Cotton/ Paper Piece, depending On Specific Project

|

MOQ

| For injection molding service, small parts ≥1,000 pcs big parts ≥ 500 pcs

|

Lead Time

| 7-12 working days if mass production quantity ≤ 10,000 pcs

|

Trade Terms

| EXW, FOB, CFR, CIF, DDP, etc.

|

Transportation

| By Express/ Sea/ Air/ Land

|

Payment Terms

| T/T, PAYPAL, Western Union, VISA, Mastercard, E-Checking, APPLE_PAY, GOOGLE_PAY, etc.

|

Detailed Photos

Company Profile

Shenzhen SQ Technology Co. Ltd, strategically located in Shenzhen, excels in crafting prototypes through advanced 3D printing and CNC machining technologies. Our expertise extends to the development of plastic injection and die-casting tools, as well as OEM temperature controller manufacturing. In addition, we proudly sell innovative products developed in-house and collaborate with partner suppliers for secondary processing of parts. With nearly eight years of illustrious business relationships in overseas markets, we've garnered acclaim and recognition through prominent exhibitions such as KSHOW, NPE, ASIAMOULD, and CHINAPLAS. In April 2020, we embarked on new collaborations, aspiring for even greater opportunities ahead. Our state-of-the-art factory spans 1500 square meters, equipped with advanced machining technology including 10 high-speed CNC machines, 2 double-head EDM, Sodick EDW, Makino EDM, and Agie Charmilles EDM, alongside fitting machines. With ISO-certified standardized management and enhanced quality control, we deliver high-precision, exquisite prototypes, and tools with unparalleled efficiency and speed. Our dedicated team ensures prompt delivery and excellence in every project. With extensive expertise in Auto CAD, PRO-E, UG, and Moldflow software, our seasoned team guarantees comprehensive solutions tailored to your needs. As we evolve into a solutions provider, our capacity reaches 200 sets per year, successfully exporting to Europe, the USA, Japan, Southeast Asia, and beyond. Our company ethos champions customer loyalty, teamwork, and the pursuit of perfection, ensuring win-win outcomes for all. We warmly invite your RFQ and visit. Rest assured, our dedicated support is always ready to assist you to the fullest.

Our Advantages

1. Uncompromised Quality Assurance2. Punctual Delivery, Every Time3. Competitive and Fair Pricing4.Skilled and Experienced Personnel5. Dependable After-Sales Support6. Stellar Market Reputation7. Proficient Team for Part & Mould Design8. Precision in Dimensional Control9. Timely and Reliable Delivery10. Comprehensive One-Year Warranty

Packaging & Shipping

We meticulously prepare essential wear parts such as springs, ejector pins, cooling connectors, and eye bolts, packaging them securely with the mould.

1. Meticulous Mould Component Inspection

2. Thorough Cleaning of Mould Cavity/Core followed by Slushing Oil Application

3. Exterior Cleaning of Mould Surface with Slushing Oil Application

4. Securely Enclosed in a Robust Wooden Case

5. Efficient Transportation via Container

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q:How to go to your factory?

You can come to us by flight. 1 hours by bullet train from Guangzhou to our city.

Q: How long is your delivery time?

A: Generally it is 25-30 days for 1st sample. or it is 60-90 days for big moulds

Q: Do you provide samples ? is it free or extra ?

A: Yes, we will send the mould testing smaple to customer, and will part two time freight fee.

Q: What is your terms of payment ?

A: 50% T/T in advance ,balance before shippment.

Q: Where is your factory located?

A: Our factory is located in ShenZhen, GuangDong city, Zhejiang Province, China. One hour from ShenZhen airport by car.

Q. When can I get the price?

A: We usually quote within 48 hours after we get your inquiry. For the urgent inquiry please let us know, we will quote to you within 24 houus

Q. I have no 3D drawing, how should I start the new project?

A: We very welcome you give us the samples, we will help you finish the 3D drawing design.

Q. If i provide you 3d drawing of my product, can you quote the price & make the mould as per the 3d drawing?

A:Yes. DWG, DXF, STEP, IGS and X_T files can all be used to quote price, make mould as per your models

>>

Warm Knitted Beanie in 3 Tones NTD1630

>>

Custom Printed Disposable Bamboo Round Chopsticks with OPP Plastic Wrapper

>>

EX200 Series Elastic Expansion Joint

>>

Manufacturer OEM Customized R410a 1Ton Air Condition 12000Btu

>>

Corrosion Exhaust fan/ Fiberglass Exhaust fan/ Fiberglass ventilation fan

>>

Hot Sale BOPP Waste Film HDPE LDPE LLDPE Plastic Recycling Machine

>>

Maize Wheat Corn Flour Meal Grits Machine Factory Milling Mill

>>

4-Way Euro Warehouse Storage Equipment Welded Steel Metal Pallet

>>

Four Colors Ball Pen

>>

Hot Selling Room Humidifier Ultrasonic Aroma Diffuser Machine Ultrasonic Humidifier Essential Oil Diffuser Portable

>>

Home Dining-Room-Furniture Dining Table of Coffee Chair Set

>>

Online Wholesale and Retail Dubai Arabic Perfume Top Selling High Quality Fragrance for Men Women Long Lasting Classic Scent Body Spray 2025

>>

Good Price 325mm 425mm Cardboard Shredder Corrugated Paper Shredder Recycling Machine

>>

YY Home China supplier customized metal combination louvre

>>

Sell 1000mm Diaphragm wall flat stop end elements B1000mm Wide Trenches for diaphragm wall construction

>>

Children′s Sports Equipment Basketball Hoop Set

>>

Disposable Medical Isolation Protective Shoe Cover Long Type SS/SMS/PP+PE waterproof clinic hospital non-sterile normal/antiskid

>>

Home Storage Rack Specialty Store Display Cabinet

>>

Small Cement Concrete Vibrator High Frequency Electric Portable Concrete Vibrator Rod Concrete-Machinery for Construction

>>

Engine parts blower motor for W164 251 oem 1648350007