|

US$4,000.00-5,000.00

|

1 Set

(MOQ)

|

Basic Info.

Surface Finish Process

Polishing

Mould Cavity

Singer or Multi Cavity

Process Combination Type

Single-Process Mode

Application

Household Appliances, Furniture, Commodity, Electronic, Home Use

Runner

Hot or Cold Runner

After-sales Service

1 Year

Product Name

Plastic Mould

Product

Paint Barrel Mold

Style

Circles, Ellipses, Squares, Rectangles

Injection Molding System

Hot Runner

Transport Package

Wooden Case

Production Capacity

150 Pieces One Year

Packaging & Delivery

Package Size

550.00cm * 530.00cm * 500.00cm

Package Gross Weight

780.000kg

Product Description

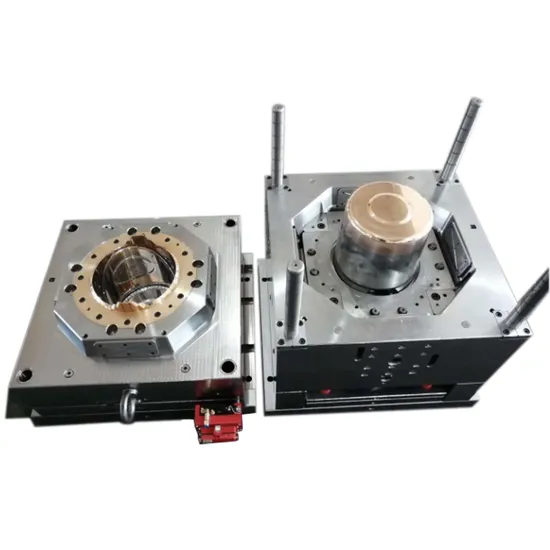

Custom High-Precision Polished Plastic Injection Mold Paint Bucket Mould with Lid and Handle Product Description

Bucket Mould Manufacturer

We are professional in plastic paint bucket mould, water bucket mould, baby bucket mould, food bucket mould, mop bucket as well as other types of plastic buckets.

For the bucket sizes, our current bucket sizes range is from 1 liter and up to 30 Liters. We are also very capable to do customized bucket moulds for other capacity.

Our factory offers a large variety of bucket shape options, the available shape includes, square, rectangular, oblong, oval and round plastic buckets.

Process of Bucket Mould Manufacturing

1. Plastic Bucket Design

2. 3D sample confirmation

3. Bucket Mold Design

4. Bucket Injection Mold Making

5. Mold Trial

6. Injection molded bucket manufacturing(if needed)

How to Ensure the Quality of Bucket Mould?

With over 10 years of experience in designing and manufacturing bucket molds, we know every details of bucket mold well and always keep "quality is 1st important" in mind during the mould manufacturing period.

Our team will study the bucket design to make sure a prefect mould struture.

As per customers' requirement, we will suggest the suitable steel material.

Before mold delivery, we will arrange at least 3 times of mold testing to ensure smooth mold running process and to get high quality bucket samples.

Feature

Project audit of plastic paint barrel (investment return audit and suggestions, product molding feasibility analysis, injection molding machine model suggestions...)

Design more competitive plastic paint barrel for customers, including analysis and design (need to provide drawings)

Weekly mold progress report (let you know the latest design and processing process, convenient for customers to arrange related work in time)

Quick response (for example remanufacturing damaged mold components)

Training support (provide training on mold operation, maintenance and mold adjusting technology for customer staff...)

Maintain and support customized special services during warranty period

Provide assistance for quality inspection of different plastic paint barrels (weight tolerance, concentricity test, stacking, drop test, seal test, etc.)

Product Parameters

| Material Science | Can use new raw materials or recycled polypropylene (PP), polyethylene (PE) |

| Style | Circles, ellipses, squares, rectangles |

| Volume | 1 L to 3 L, 1 gallon to 5 gallon etc... |

| Decoration method | Mold labeling (IML), heat transfer printing, digital printing... |

| Mold Name | Paint barrel mold |

| Product size | 20L |

| Cavity | 1 cavity |

| Mold size | 700x700x750mm |

| Suitable machine | SE-460T |

| Mold main material | 718H + copper beryllium |

| Injection molding system | Hot runner |

| Mold ejection system | Ejector plate |

| Mold cycle time | 28S |

| Mold features | in order to speed up the injection molding cycle, copper beryllium is inserted into the core and cavity of the mold. |

Properties Strength - it needs to be strong and durable, and can be used to hold organic chemical polymer materials such as paint.

Static and dynamic loading capacity requirements.

Sealing performance - ensure the quality of paint and no leakage during transportation.

Stacking - saves storage space and is easy to transport.

Antistatic agents - prevent dust and dirt.

UV protection - as a basic requirement for storage and transportation.

Filling paint temperature requirements.

Reaction to chemicals - test the reaction of paint barrels to various chemicals, hopper shall be solvent resistant and can be safely applied to all paint loading.

Detailed Photos

Final Product

Company Profile

>>

Aluminium double glass casement window glass price aluminum profile window casement window

>>

Automatic Fast Speed Feather Jacket Weighing and Filling Machine with Twelve Weighing Units (R2-12)

>>

75 Degree High Cop High Temperature R290 Air to Water Heat Pump Suitable for Cold Areas

>>

Ye100-Bf, Capsule Pressure Gauge, 4", Micro Pressure, All Stainless Steel, Lower Mount

>>

China Suppliers Mix Color Natural Marble Mosaic for Floor

>>

Ca*T Mini Excavator Original Crawler Excavator for Sale

>>

GAPV High Quality Hot selling Auto Parts Engine Cover For Crown GRS182 OEM 51410-0N010 2005- Year

>>

Florida approved hurricane villa home manual aluminum awning window for house

>>

Metal Sorting Machine/ Eddy Current Separator for Aluminum and Copper Non Ferrous Metal Separator

>>

Selective Laser Melting Additive Manufacturing Equipment for Metalwork Metal Printer

>>

11cm/9cm/7cm Fabric Cutter T-Shirt Woven Fiber PVC Fabric Cutting Machine

>>

XIAOMI HOTO 10 Pieces Cordless Screwdriver 3.6V Li-Ion Battery Electric Drill DIY Woodworking Drill Bit Set S2

>>

Extruder Compounding Machine/PTFE Granulating Extruder Machine/Plastic Extruder Granulator

>>

Plastic Upvc Frame Glass Accordion Doors Folding Door Design Bi Fold Doors Exterior

>>

PPE Beauty Salon, Tattoo, General Purpose Disposable Vinyl Nitrile Gloves

>>

Solid Carbide 1 Flute Upcut Spiral End Mill CNC Router Bit Milling Tools Cutter CNC Router Bits for Wood

>>

Popular New Design Adjustable Type Tractor Suspension Tractor Leveling Satellite Agri GPS Grader Mounted Satellite Land Leveller

>>

Laminate Flooring Eco IXPE Foam Acoustic Underlay

>>

Heat Shrinkable Tube Casing Pipe Printing Wire Cable C280t Tube ID Printer

>>

Wood Waste Shredder Wood Chipping Machine