|

US$227,538.00

|

1 Piece

(MOQ)

|

Basic Info.

Model NO.

QH-1600/1800/2200

Certification

ISO 9001:2000, CE

Suitable for

Recycled Material, Wood, Paper

Paper Thickness

Normal Specification Paper

Product Name

Qh-2200 5 Ply Corrugated Board Line

Corrugated Shape

a,C,B,E,F Flute

Number of Cardboard Layers

2,3,5 Ply

Land Occupation Length

80m

Production Capacity

50 Sets/Year

Product Description

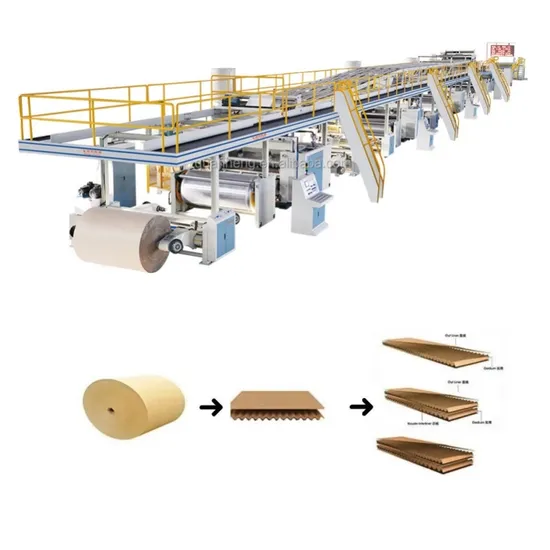

5 Ply Corrugated Paper Board Production Line

Product Description

| 1 | Effective width | 2200mm | 2 | Design produce speed | 150m/min |

| 3 | Three layer work speed | 100-140m/min | 4 | Five layer work speed | 120m/min |

| 5 | Seven layer work speed | ------------------- | 6 | The highest change single speed | --- |

| 7 | Longitudinal separation accuracy | ±1mm | 8 | Cross-cutting precision | ±1mm |

note | Speed the above targets required to achieve:effective width1800mm,Comply with the following standards and ensure the paper's equipment condition 175 ºC heating surface temperature. |

| Top paper index | 100g/m2--180g/m2 Ring crush index(N.m/g)≥8 (Water containing8-10%) |

| Core paper index | 80g/m2--160g/m2 Ring crush index(N.m/g)≥5.5 (Water containing8-10%) |

| In paper index | 90g/m2--160g/m2 Ring crush index(N.m/g)≥6 (Water containing8-10%) |

| 9 | Flute combination | |

| 10 | Steam requirement | The maximum pressure 16kg/cm2 | Common pressure10-12kg/cm2 | use4000kg/Hr |

| 11 | Electricity demand | AC380V 50Hz 3PH | Total power≈250KW | Running Power≈150KW |

| 12 | Compressed air | The maximum pressure 9kg/cm2 | Common pressure4-8kg/cm2 | use1m3/min |

| 13 | space | ≈Lmin75m*Wmin12m*Hmin5m(The actual drawing to provider to provide audited prevail) |

Detailed PhotosSpindle ¢ 240mm, hyperbolic heavy rocker, expand chuck,multi-point brake,hydraulic drive lifting, panning left and right on the middle.Guide rail length 6000mm,use of plate welding.

Rail length6000mm,trolley used 10mm plate welding.

Corrugated main roller ¢320mm,material with 48CrMo alloy steel,Tile roll modular group lifting transfer.Airbag ballasting structure,import main bearing,PLC automatic control glue,HMI touch screen,Breaks automatic parking relief,steam heating way.

Corrugated rollerφ320mm,48CrMo high quality alloy steel, tungsten carbide treatment

Fast change the roller in 15 minus by electrical trailer

Airbag ballast structure

Independent glue unit with PLC control,circulating supply glue

Man-machine interface display

Automatic stopping machine and relief pressure without paper

roller ¢900mm,including pressure container certificate.Electric adjustment wrap angle.Wrap angle can adjust the paper preheat area in the range of 360°.

Rack 360 mm GB channel,Chrome hot plate 600 mm *16 pieces,4 M cooling section,The whole structure of the hot plate design.PLC automatic control press plate. Temperature display, frequency motor.

--Blade adopt tungsten alloy steel

--Adjusting(blade and scorer) and grinding by computers

--Electric correct

--6 blade 10 line

--Automatic tracking of line speeds

--Changing order in8-15 seconds

--Fully servo motor and servo control

--Storage 200 sets orders

--Three different pressure line can be switched automatic

--Zero pressure line

Full AC servo control, energy storage brake, helical blade structure, oil-immersed gears,10.4-inch touch screen display.

Company Profile

Packaging & Shipping

FAQ Q:Are you manufacture or trading company?A:we are manufacture , our factory set up on 1999, and before we exported our products are mainly supply to the trading company ,so we are the source factory, welcome to be our agency.Q:Do you inspect the finished products?A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .Q:Does the packing strong?A:Yes, of course! All of our export packing with strong wooden tray, all to meet the export packaging standards.Q:How about after-sales service process?A:When your machine has problem, contact our sales and we will solve your problem as soon as possible.We have after-sale office in China, Vietnam, India, Bangladesh, Italy. Q.Where is your factory?A:Our factory located in Development Zone, East Of DongGuang County, CangZhou City, Hebei Province,China,welcome to visit our factory!Q. Do you have Import & export right?A:Yes , we have , so we can export the carton machines to you directly , without any trading company agency

>>

Haorui New Style Full Automatic Plastic Recycling Machine

>>

New Design Fashion Cuffed Unisex Winter Cap Knitted Beanie Hats

>>

Jasu Plastic Pet Snacks Food Jars Cans Automatic Plastic Injection Stretch Blow Moulding Machine

>>

Best Selling Clothing Luxury Carry Shoulder Womens Tote Custom Shopping Canvas Bags

>>

Tapestry Upholstery Cotton Fabrics 100% Waterproof Sofa Cover Fabric Material Polyester Spandex

>>

Animal Husbandry Equipment Sow Limit Crate Single Crate

>>

Auto Timing Chain Kit for NISSAN Engine Parts Timing Tensioner and Guide TK9080-2

>>

Rod mill bearing cement industry electric power equipments spare parts

>>

for Liquid, Solid Test High Quality 80GHz Radar Level Meter Level Sensor

>>

Vertical Turret Lathe Normal Conventional Manual

>>

Factory Price Window Flyscreen Window Screen Mesh

>>

Taijia Nitrogen Digital Rotameter co2 rotameter liquid chlorine rotameter

>>

Zoyer Zy987t-4 4-Thread Cylinder Bed Overlock Sewing Machine

>>

stainless steel sesame seeds skin peeling machine/sesame seeds hulling machine

>>

IP65 waterproof 100W SOLAR LED STREET LIGHT

>>

Mold Production Yokohama Type Marine Ship Factory Directly Supply Pneumatic Rubber Fenders

>>

CS Home Modern Home Furniture Restaurant Hotel Marble Top Wooden Frame Room Dining Table

>>

Top Sell Fitness Yoga Pants Women European and American High Waist Sportswear Leggings Breathable Wicking Hip Pants

>>

Quality guaranteed multifunction 2-tier drawer holder mesh wire spice rack bathroom kitchen bathroom storage organizer

>>

Electric trackless transfer cart used in beverage factories