|

US$12,417.00-16,183.00

|

1 Piece

(MOQ)

|

Basic Info.

Processing Accessory

Centre CNC Lathe

Automatic Grade

Automatic

Axis Number

Each Knife Have Two Axis

Mini Processing Diameter

3 mm

Transport Package

Wood Box

Specification

1550*1060*1650mm

Production Capacity

60sets/Month

Packaging & Delivery

Package Size

1650.00cm * 1150.00cm * 1800.00cm

Package Gross Weight

1800.000kg

Product Description

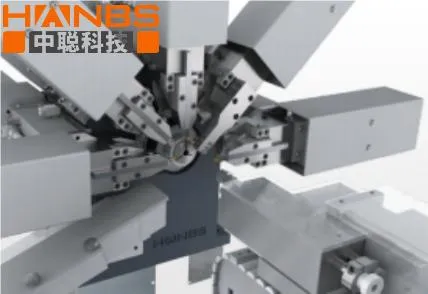

Hanbs New Machine in Higher Rigidity Double Spindle and Different optional functions Swiss CNC Lathe with Higher Performance HS-W20

The Zhongcong W20 adopts a five channel CNC system, with an 10 axis absolute value servo motor and spindle servo motor. It can process products with five cutting tools simultaneously. Not only is the processing efficiency several times higher than traditional equipment, but the operation is simple and easy to learn, and programming is fast and convenient.

Technical parameter:

control system

| HANBS self-innovate (yn 1.0 versions)

|

Servo axis number

| Standard 12 axis

|

Programming method

| 5-channels G code programming, each axis can be programmed separately

|

The number of knives

| Group 5

|

Maximum machining diameter

| Φ15mm Φ20mm

|

Maximum machining length(50mm in guide mode)

| The walking knife mode is 50mm

|

Maximum axial bore diameter

(When the back shaft is 12mm and the handle is 10mm)

| Φ6mm

|

Drilling arm handle diameter

| ∅5(Three)∅6(Two)

|

Attack capability (spindle reversal mode)

| M6 Copper

|

Dental tapping ability (doraxial delivery)

| M5 Copper

|

Car thread function

| Yes

|

Multi-knife synchronous processing function

| Yes

|

Radial max bore diameter

| Φ7mm

|

Radial max bore tapping size

| M5

|

Maximum clamping diameter of the back side spindle

| ∅12mm

|

Maximum bore diameter of the back-side spindle

| ∅6mm

|

Maximum tapping diameter of the back-side spindle

| M6

|

Spindle power

| 2KW(With the function of score)

|

Backside platform axle power

| 1.0KW

|

Maximum spindle speed(For short use only)6000rpm

| 6000rpm

|

Back maximum speed (for short use only)

| 6000rpm

|

Maximum removal length of piece

| 50mm

|

Side power tool unit (optional)

| 2

|

End face power tool unit (optional)

| 1

|

Row knife ( 8 * 120 * 3))

| 3

|

Standard maximum number of tool installed

(5 knives + 5 drill / boring)

| 10

|

High maximum number of tool installed

(5 + 5 drilling / boring + 1 back strong drill)

| 11

|

Knife size

| 8*8

|

Z1.2.3.4.5 axial stroke

| 50mm

|

X1.2.3.4.5 axial stroke

| 30mm

|

Backshaft itinerary

| 150mm

|

X1.2.3.4.5 axial power

| 400W

|

Z1.2.3.4.5 axial power

| 400W

|

Z1, Z2, Z3, Z4, Z5, and Z2 axis fast-forward speed

| 30m/min

|

X1, X2, X3, X4, X5 axis fast forward speed

| 30m/min

|

Center height of spindle

| 1010mm

|

High version input power

| 7.6KW

|

weight

| 1800Kg

|

Fuel tank storage

| 50L

|

size

| 1550*1060*1650mm

|

Some pictures about HANBS

Some pictures about delivery

Installing parts

Foreign customers visit the company

Exhibition photos:

Cast iron display

Some photos about optical machine display:

Samples display

F&Q

Q1.Are you manufacturer or trading company?

A. We are professional machine tool manufacturer, we set export sales center & showroom in Dongguan city.Welcome to visit.

Q2. How can I place order and get more details about the machine ?

A: You can contact us by email or on line and tell me which details you want to know I will send you the processing vedio and photos.

Q3. About the price can you give the favourable or best price?

A. We have different series machine,and we will recomand you the suitable machine according to your products.Our aims is to become long-term cooperation and friends so we will give you the favourable price for you.

Q4.Can you provide some certificate?

A. According to different country,we can provide different certificate which you need.

Q5.What kind of products your machine can processing?

A.Maxi processing diameter is 46 mm.Mini processing daimeter is 3mm.And you can send me the drawings about your products our engineer will do the assessment.

Q6.How will the machine be transported?

A.We transport machine by sea and the port is Shenzhen.

Q7.What is the features about the machine?

A.High precision and rigidity,improve customers' production and help customer to solve the problems.

Q8.How will the machines be packed?

A.We will fix the machine axial and pack it in wooden cases,make sure that the machine not be damaged.

>>

Sliding windows certified by AS2047,AS2208 with double glazed

>>

Supply Organic Chemical Food Grade CAS No. 77-92-9 30-100 Mesh Ca/Citric Acid Anhydrous

>>

Laminator Machine for A3 OL387 Thermal plastic laminator Machine for Home Office School Use

>>

High Quality Agricultural Machine 1ly Series 18-160HP Tractor Trailed 3 Point Hitch 2-6 PCS Disc Plow Plough From China Manufacturer Factory

>>

High Quality TPU Transparent Silicone Strap For Apple Watch Case Band Mate for Apple Watch Band Clear Rubber for iwatch 38/44mm

>>

BTG-UK2 Thermostat Guard for Air conditioner Thermostat Temperature Control Plastic Box Cover Case With Lock Key Good Quality

>>

High Quality 1080P 8 channel mdvr truck car mobile dvr mdvr 4ch 8ch 4g / gps / wifi 4 cams for vehicle

>>

Lenado 9700 Long Life Customize New Product High Precision Popular Flannelette Loom

>>

Alonmax Sample Free Heavy-Duty Three Phase Energy-Saving Ie5 AC Electric Motors

>>

CNC Vertical Machining Center Vmc967vs High Speed Universal Vertical Machine Center

>>

9mm 11mm malaysia electrical cable puller 4mm fish tape wire fiberglass duct rodder

>>

Factory Price Trailer Concrete Mixer with Diesel Engine for Sale

>>

Rubber Crusher Roller for Rubber Without Steel Wire with a Higher Intensity

>>

45tons LCD Display Rotary Table Vertical Plastic Injection Moulding Machine

>>

Precision Aluminium Die Casting Company

>>

Common Rail Fuel Injector Nozzle RE533608 for John Deere RE522250 RE533608 BEBE4C12001

>>

Custom Die Cut Printed Magnetic Refrigerator Rubber Fridge Magnets Sticker

>>

Wholesale Kinds of Flower/Succulent/Cactus Handmade DIY Plant Pot

>>

Premade Bag Packing Doypack Bottle Water Honey Oil Tomato Paste Ketchup Juice Pouch Fruit Liquid Packaging Machine

>>

3-Axis Vertical Machining Center High-Quality Metal Processing CNC Milling Machine