|

US$28,500.00-182,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Automatic Grade

Automatic

Certification

GS, CE, ISO 9001

Control System

Fanuc, Siemens, Mitsubishi

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

2400*2000*1900

Production Capacity

1000/Year

Packaging & Delivery

Package Size

240.00cm * 200.00cm * 190.00cm

Package Gross Weight

3800.000kg

Product Description

Product Description

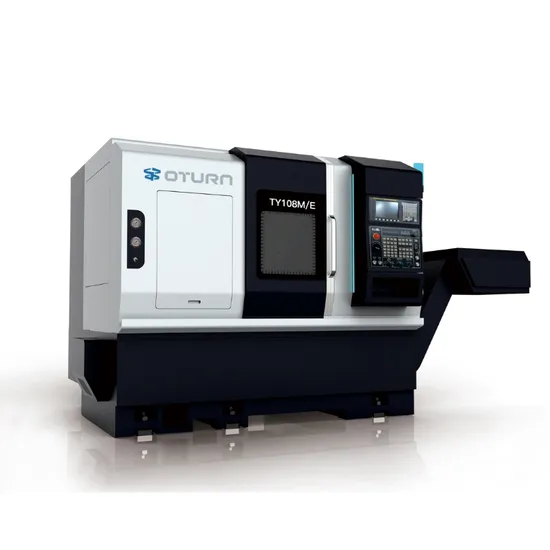

The machine adopts optimized 30 degree tilting structure design, which also provides high precision, super rigidity and excellent machinability. High-strength HT300 cast iron one-piece solid structure lathe, using finite element analysis, so that the machine tool as a whole has excellent rigidity and stability, which can maintain reliable accuracy for a long time, improve machining stability and tool life, and eliminate stress.

While improving precision and stability, high strength roller linear guide design structure, transmission system adopts screw preloading design to improve the rigidity performance, and the appearance is simple and generous, in line with the trend.

Main features of this machine tool:

1. Adopting a 30° inclined layout and an integrated structure of the bed base, which greatly improves the bending and torsional rigidity of the machine tool during operation. The high rigidity and high stability of the integrated bed base provide high precision for the entire machine. A strong guarantee.

2. Adopt direct drive synchronous spindle device: magnetic ring incremental encoder (sine and cosine) positioning accuracy: 20 arc seconds, C-axis indexing accuracy: 40 arc seconds. Effectively eliminate spindle vibration, and the nose deflection accuracy is within 0.002MM. Improve the surface finish of the workpiece, adopt a rear-mounted rotor, which makes installation and maintenance faster, the spindle motor is equipped with a cooling system to suppress the influence of thermal displacement and ensure a constant operating temperature of the spindle. The spindle system has undergone strict dynamic balance testing. The good accuracy retention, high rigidity and high efficiency enable the whole machine to not only complete finishing, but also perform rough machining and heavy cutting for users. It is especially suitable for mass production of complex shapes and high smoothness. product.

3. High rigidity overall design servo turret. Equipped with a high-precision clutch to ensure its positioning accuracy and repeatable positioning accuracy. It is equipped with a servo motor to drive the cutterhead to rotate for bi-directional or arbitrary tool selection. The hydraulic principle is used to loosen and clamp the clutch, and the proximity switch feedbacks the clutch action signal to quickly and accurately achieve the tool change action.

4. The machine tool is equipped with roller linear guides and ball screws. The heat-treated and precision-ground ball screws can ensure the best accuracy and durability. Each axis adopts a direct transfer axis structure and a double-anchor pre-relay method to ensure thermal stability. The amount of displacement is minimized, greatly improving processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain intact accuracy when the machine is subjected to impact, and the displacement is smooth and low-noise, which can extend the service life.

5. Programmable hydraulic tailstock and high rigidity integral tailstock can eliminate vibration and have good stability. Programmable or manual button control, convenient, fast and reliable.

6. This machine provides users with a complete hydraulic and lubrication system, using high-quality hydraulic pumps, hydraulic valves and other components to greatly reduce the failure rate. The hydraulic and lubrication systems are designed to be simple and reliable. The machine tool adopts centralized quantitative automatic lubrication.

7. It adopts Taiwan rotary chuck cylinder and optional automatic chip removal device, which can greatly reduce the labor intensity of the operator and achieve safe and efficient production. The above functional components can be programmed and controlled, and various functions can be designed and installed according to the special requirements of the user special fixture.

Product Parameters

| Item | Unit | TY108M/E |

| Max. swing diameter over bed | mm | Φ600 |

| Max. processing diameter | mm | Φ310 |

| Max. processing diameter over tool holder | mm | Φ200 |

| Max. processing length | mm | 320 |

| Distance between centers | mm | 450 |

| Spindle type | type | A2-6 |

| Max. spindle speed | rpm | 4300 |

| Hydraulic Cylinder/ Chuck | lnch | 8″ |

| Spindle bore diameter | mm | Φ66 |

| Max. bar diameter | mm | Φ52 |

| Direct drive spindle motor power | kw | 18/22 |

| Direct drive spindle motor torque | Nm | 91-227 |

| X/Z axis travel | mm | 200/400 |

| X/Z axis rail specifications | spes | Roller35 |

| X/Z axis motor power | kw | 1.8/1.8 |

| X/Z axis rapid speed | m/min | 24 |

| X/Z axis positioning accuracy | mm | ±0.005 |

| X/Z axis repeatability | mm | ±0.003 |

| Power turret type | pcs | BMT45-12T |

| Power turret motor | KW/Nm | 5.5/35 |

| Max. power tool holder speed | rpm | 6000 |

| External diameter tool holder specification | mm | 25X25 |

| Internal diameter tool holder specification | mm | Φ40 |

| Adjacent tool change time | sec | 0.15 |

| Positioning accuracy | / | ±2" |

| Repeatability | / | ±1" |

| Hydraulic tailstock | / | Programmable hydraulics |

| Max. Tailstock travel | mm | 360 |

| Tailstock sleeve tapered hole | type | Mohs4# |

| Sleeve diameter | mm | 80 |

| Sleeve travel | mm | 100 |

| Machine size | mm | 2400*2000*1900 |

| Machine weight | kg | 3800 |

| Cutting fluid tank volume | L | 150 |

| Hydraulic unit box volume | L | 40L |

| Hydraulic pump motor power | kw | 1.5 |

| Lubricat tank volume | L | 2 |

| Automatic lubrication pump motor power | W | 50 |

| Coolant water pump power | W | 750 |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1:How can l choose the most suitable machines?

A: Please tell me your specifications, and we will help you select the best model, or you can choose the exact model yourself. Alternatively, you can send us the product drawings, and we will recommend the most suitable machines for your needs.

Q2: What are the main products of your company?

A: We specialize in all kinds of machines, such as CNC Lathe Machine , CNC Milling Machine, CNC Turning Machine, Vertical Machining Center, Horizontal Machining Center, Lathe Machines, Turning and milling composite processing so on.

Q3: Where is our factory located? How can l visit there?

A: We have 5 factories located in Guangzhou, Quzhou, Ningbo, and Guangdong. You are warmly welcome to visit us.

Q4. How do you transport it?

A: Provide Transportation Solution DDP/CIF/FOB/FCA

Q5: What are the Payment Terms?

A: T/T, 30% initial payment when ordering, 70% balance payment before shipment

Q6:What's the OMQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

We want to know:

1. We strongly suggest you tell us the size, and material of your workpiece for our evaluation, if possible, better to send us a workpiece drawing so that we can recommend you the most suitable model.

2. If need a CIF Price, please kindly tell us the port of destination.

>>

Custom Logo Printed Promotional Cheap Outdoor Waterproof Sport Running Waist Bag

>>

PE PP Pet Waste Plastic Granule Production Pelletizing Machine

>>

Fermentation Tank Organic Fertilizer Fermentation Tank Fermentation Tank

>>

Innovative CNC Molding Tool Grinder with CE Compliance and OEM/ODM Features

>>

Electric Small Grain Wheat Spice Flour Corn Mill Grinder Machine for Sale

>>

Stainless Steel Milk Machine Dairy Machine Farm Machinery Milker

>>

Construction Material Galvanized Facade Cladding Expanded Metal Mesh

>>

Hot Selling PE Multipurpose Polyethylene Transparent Wrap Film Bags Wholesale

>>

Small Rolls of PTFE Adhesive Tape

>>

62400g4AA0 Car Body Kits Subframe for KIA Ceed CD 2019

>>

2022 New Arrival Er Yag Laser 2940nm Nd Yag 1064nm Laser Fotona 4D Skin Tightening Machine

>>

bamboo sticks for incense

>>

Outside Of Bend Tube Shield

>>

Hot Sale Glass Drilling Laser Machine with User-Friendly Operation Interface

>>

Automatic Bridge Edge Polishing Machine for Granite Marble

>>

SIASUN Duco Cooperation us Robotics Arm Automation Autofocus Computer Vision IPRAS ( Intellegient Passive Random Focus System ) 35mm 1.2" 25Mpixel C mount Autofocus with motorized & algorithm Support for vision inspection

>>

200L Integrated High Pressure Solar Hot Water Heater with Heat Pipe for Residential House

>>

Quilt Polyester Wadding Production Line Cotton Carding Machine Polyester Wadding Machine

>>

Full Automatic Durable River Cleaning Boat Aquatic Weed Harvester

>>

Tianhe Low Temperature 2mm Thick Transparent PVC Strip Door Curtain Roll