Basic Info.

Species

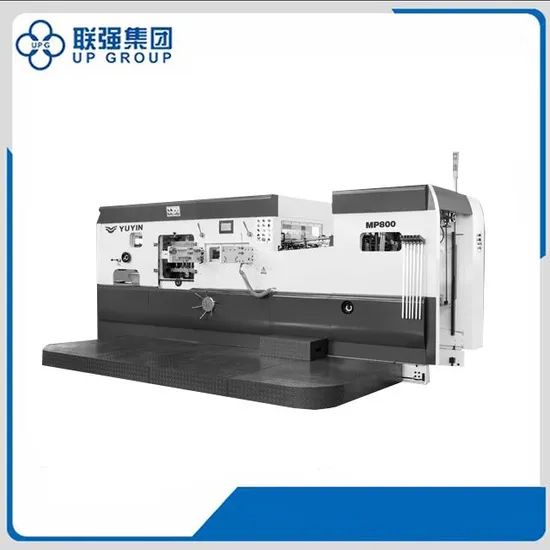

Die Cutting and Creasing Machine

Computerized

Computerized

Automatic Grade

Automatic

Application

Paper Packaging Materials

Max Die-cutting Size

790X610mm

Max Cutting Speed

8000s/h

Transport Package

Package

Specification

10 x 4 x 2m

Product Description

Product Description Compare with MY800, MY800E has the following advantage:

Pneumatic Plate Locking Device: easy to lock the plate Electric Pressure Adjusting System: easy to adjust the pressure, no need to turn the hand wheel, can adjust the pressure in the Interface. MY800E automatic die-cutting and creasing machine is mainly used for the die-cutting, creasing, cold and hot embossing of cigarette box, drug box, wine box and label in the packing and decorating industries.

This kind of machine is incorporated with fully automatic feeding, die-cutting, delivering counting, obstacle indicating, checking and measuring. It has the features of easy operating, reliability, high speed and precision.

It has the features of high pressure, fast speed and high precision.

Adopt pneumatic clutch, which ensures stable braking.

Adopt programmable controller, and it is incorporated with fully automatic feeding, die-cutting, delivery, obstacle indicating, checking and measuring.

Adopt coder in controlling program, which makes the running of the machine coordinately.

The sheet-conveying unit adopts adjustable construction, ensuring speed and precision, especially fits to the conveying of thin sheet.

Pneumatic sampling system makes the sample-checking more convenient.

All the electrical are the products that have got CE certificate, every safeguard coincides with CE standard, safe and reliable.

Detail characteristics

Safety system

The machine with four degree safety class has got CE certificate of high-speed and stable performance.

Electrical unit

Imported electronic elements and panels with humanization control layout to ensure easy operation. Equipped constant temperature devices to ensure reliable working and prolong service life.

Feeding unit

The design of double column type pre-stack unit ensures convenient and efficient operation. Feeder with collision-prevention device. Adopt high-speed feeder with adjustable strong type suckers to guarantee stable and smooth paper feeding.

Movable Platform

Unique cast structure and specific working process ensure evenness and flatness and pressure-regulating time. Oil cooling system ensures constant pressure.

Die-cutting unit

Worm shaft, worm wheel and crankshaft with unique working process greatly improve the service life of core components. Single gripper bar can be fine adjusted to achieve processing requirement.

Pneumatic clutch

Imported components to lower noise and pneumatic impact for stable and safe running.

Front Lay

The front lay can be individually adjusted by four site for different paper processing requirement. Unique electrically pressure-regulating device realizes plate regulating

in delivery unit, ensuring convenient and efficient front lay regulating. Values visually displayed on man-machine interface.

Delivering unit

Detail characteristics

Safety system

The machine with four degree safety class has got CE certificate of high-speed and stable performance.

Electrical unit

Imported electronic elements and panels with humanization control layout to ensure easy operation. Equipped constant temperature devices to ensure reliable working and prolong service life.

Feeding unit

The design of double column type pre-stack unit ensures convenient and efficient operation. Feeder with collision-prevention device. Adopt high-speed feeder with adjustable strong type suckers to guarantee stable and smooth paper feeding.

Movable Platform

Unique cast structure and specific working process ensure evenness and flatness and pressure-regulating time. Oil cooling system ensures constant pressure.

Die-cutting unit

Worm shaft, worm wheel and crankshaft with unique working process greatly improve the service life of core components. Single gripper bar can be fine adjusted to achieve processing requirement.

Pneumatic clutch

Imported components to lower noise and pneumatic impact for stable and safe running.

Front Lay

The front lay can be individually adjusted by four site for different paper processing requirement. Unique electrically pressure-regulating device realizes plate regulating

in delivery unit, ensuring convenient and efficient front lay regulating. Values visually displayed on man-machine interface.

Delivering unit

Add foot-pressing preventer for further safety. Unique deceleration hairbrush ensures paper stopping stably. Tension device for drive chain of gripper bar prolongs the gripper bar's service life. Pneumatic sampling device for convenient sampling at any time with the machine running.

Feeding unit

Drive chain adopted in feeding unit to ensure stable run and reliable paper feeding. Gas spring for easy and convenient operation. Adjustable reduction unit for paper to front lay, helps to thinner paper positioning at high speed. Side lay with dual purpose for side positioning can be easily switched.

Gripper bar chain

The gripper of special structure and material to guarantee low moment of inertia and impact. Special gripper structure to ensure stronger gripper force and working accuracy at high speed. Adopt optimized motion trail and improved motion curve to ensure stable and accurate running of gripper bar. Imported chain to prolong service life.

Product Parameters

| Max. Paper Size (mm) | 800X620 |

| Min. Paper Size (mm) | 360 X 290 |

| Max. Die-Cutting Size () | 790X 610 |

| Max. Die-Cutting Speed (s/h) | 8000 |

| Max. Stripping Speed (s/h) | 6500 |

| Max. Working Pressure (T) | 200 |

| Die-cutting Precision (mm) | ≤±0.1 |

| Sheet Thickness (mm) | Cardboard: 0.1 -1.5

Corrugated Board: ≤4 |

| Net Weight (T) | 11 |

| Total Power (kw) | 17.55 |

Overall Dimensions (mm)

(Not include the foot plate) | 4850x1785x2000 |

Company Profile

Superiority

Our Customers

Exhibitions

Our Services Pre-sales Service

We provide all information and materials of our products to the valuable customers and partners so as to support their business and development. We also will give a preferential price for the first few machines, the samples for the printing, packaging and consumables are available, but the freight should be borne by the customers and partners.

In-sales Service

The delivery time of the ordinary equipment is generally 30-45 days after receipt of deposit. The delivery time of the special or large scale equipment is generally 60-90 days after receipt of the payment.

After-sales Service

The quality guarantee period of the product is 13 months after leaving the Chinese port. We can provide customers with free installation and training, but the customer is responsible for round-trip tickets, local meals, accommodation and engineer allowance.

If the product is damaged due to customer's incorrect handing, the customer should bear all the costs including the costs of spare parts and freight charges etc. During the warranty period, if it is damaged caused by our manufacturing failure, we will provide all repair or replacement free of charge.

Other Service

We can design special products according to customer's requirements on various aspects, including style, structure, performance, color etc. In addition, OEM cooperation is also welcome.

>>

Haide Apm Wheat Rice Threshing Machine China Factory Apm500 Multifunction Commercial Large Rice Sheller Machines/Multi Crop Thresher

>>

Factory product double tempered glass aluminum profile shutter/louver window crank devices hardware

>>

Waterproof Canvas Tool Bag

>>

Versatile Automated 1.5/ 2 Tons Self-Driving Electric Agv Forklift for Factory and Warehouse

>>

Animal Pet Dog Cat Cattle Cow Horse Floating Sinking Fish Feed Food Processing Making Extruder Machine

>>

CBB65 Wire Type Capacitor

>>

05149097AA Oil Pressure Switch for Jeep Kk Cherokee Wk Commande 1 Pin For Chrysler Dodge Dakota Valvula Presion Aceite for Jeep

>>

HSS M42 Bimetal Band Saw Blade

>>

Food Grade Best Algae High Protein Spirulina Powder with Free Sample

>>

Manual Measuring Tool Tape Measure Retractable Steel Tape Measure with Roll

>>

High Speed with Cheap Price Single Head 4/6/9/12/15 Needles Computerized Embroidery Machine Price in China Similar Astajima and Brother Embroidery Machine

>>

SM3019 ECE R65/SAE LED VISOR LIGHT

>>

Solas Standard Totally Enclosed Freefall Lifeboat with ABS Certificate

>>

Portable 24 Coat Rack With Shelf 2 Tier Garment Target

>>

CD6140X2000 Electronic Lathe Suitable for Turning Threads Disc-Shaped and Shaft-Type Parts with High Precision and Good Quality

>>

ceasing perforating machine 500mm manual electric creasing machine

>>

Metal Pure N4 N6 Ni200 Ni201 Precision Chrome Nickel Alloy Strip for Battery

>>

741-812, 15231244, 25715115, 25750518 Passenger Side, Rear, Right Power Window Regulator with Motor for Buick

>>

High Quality Engineering Construction Crusher Rotating Type Hydraulic Pulverizer for Excavator

>>

897493M1, 897493M94 Tractor Engine Piston Ring for Massey Ferguson