|

US$3,611.00-111,111.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Material

Animal Raw Materials, Forest Products, Special Agricultural Products, Garden Products, Agronomic Products, Natural Ingredients, Paratha Production Line

Application

Pet Food, Chocolate, Ice Cream, Vegetable, Fruit, Dairy, Beverage, Paratha Production Line

Certification

CE, MET, SA8000, ISO9001, Customized

Automatic Grade

Automatic

Advantage

Easy Operation,High Productivity

Basic Function

Paratha Production Line

Overall Dimension

24000X2600X2000 mm

Safety Standard

CE Certification

Emergency Stop Function

Yes

Sustainability Attribute

Recyclable

Transport Package

According to Customer′s Demand

Specification

24000x2600x2000 mm

Production Capacity

According to Customer′s Demand

Packaging & Delivery

Package Size

99999.00cm * 99999.00cm * 99999.00cm

Package Gross Weight

99999.000kg

Product Description

PRODUCTION OVERVIEW

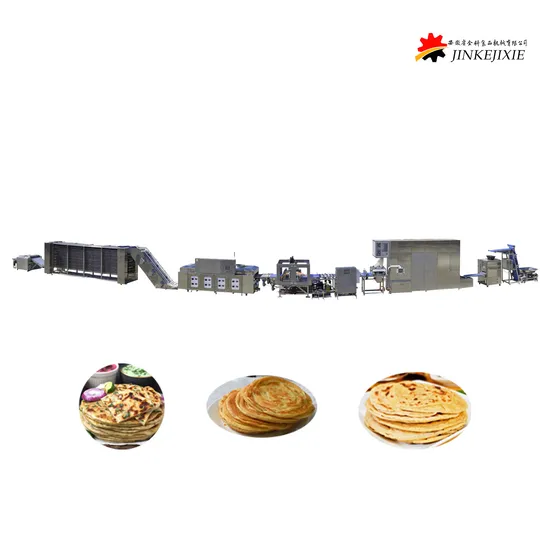

PARATHA PRODUCTION LINE

Paratha production line is an automated and efficient food processing equipment that can complete a series of production processes from dough making, cake pressing, molding, baking to packaging. This production line is widely used in cake food processing enterprises, which can significantly improve production efficiency, reduce labor costs, and ensure the stability and consistency of product quality. It is mainly composed of dough mixer, dough dividing machine, cake press, forming machine, baking equipment, packaging machine and other equipment. Paratha production line has a high degree of automation, high production efficiency, stable product quality and low maintenance cost. Using advanced automation and control systems, the Paratha production line is capable of producing thousands of pies per hour. At the same time, the Paratha production line also supports customization services, which can be personalized designed and configured according to the specific needs of customers.

| Paratha Production Line |

| Name | Paratha Production Line |

| Condition | New |

| Advantage | Easy Operation,High Productivity |

| Power | 12.3kw |

| Speed | Adjustable |

| Overall Dimension | 24000x2600x2000 mm |

| Equipment Weight | 2200kg |

| Material | Stainless Steel |

| Automatic Grade | Automatic |

| Appearance | Customized |

| Safety Standard | CE Certification |

| Protective Measure | YES |

| Emergency Stop Function | YES |

| Sustainability Attribute | Recyclable |

| Warranty Period | 1 Year |

| Voltage | 380V |

PRODUCTION DETAILS

One Line With Nine Ferment Dough

| Capacity | 3000 |

| Overal dimensions | 7279×1520×4000mm |

| Power | 2 kw |

| Time | 10-15 min |

Fully Automatic Dough Elevator

| Voltage | 380V 50HZ |

| Overal Dimensions | 1850×1150×2500 mm |

| Power | 1.1 KW |

| Weight | 150 KG |

Dough Lump Spacer

| Overal dimensions | 1447×1151×11 00 mm |

| Power | 0.95 kw |

| Pressure range | 100 kg |

One Out Four Laminating Machine

| Equipment size | 2500x1000x1400 mm |

| Power | 1.15 kw |

| Capacity | 4500-6000 pcs/h |

| Pessure | 0.8-1.0 MPa |

| Production diameter | 120-140 mm |

| Production weight | 60-150 g/pcs |

OX Tongue Pastry Laminating Machine

| Equipment size | 2500x960x1400 mm |

| Power | 1.15 kw |

| Capacity | 1500-2500 pcs/h |

| Pessure | 0.8-1.0 MPa |

| Production diameter | 80×220 mm |

| Production weight | 80-150 g/pcs |

Circular Film Laminating Machine

| Equipment size | 3400x1040x1730 mm |

| Power | 2.5 kw |

| Capacity | 2500-4000 pcs/h |

| Pessure | 0.8-1.0 MPa |

| Production diameter | 80-110 mm |

| Production weight | 80-150 g/pcs |

Main Features

1. Dough Mixer: used to mix flour, water, oil and other raw materials into a uniform dough. The equipment has precise mixing ratio and mixing speed control to ensure the quality of the dough is stable.

2. Dough Press: press the mixed dough into thin sheets for subsequent processing. The tablet press usually adopts a high-precision roll design to ensure uniform thickness and smooth surface.

3. Forming Machine: The pressed sheet is cut into round or square slices suitable for making burritos. The molding machine can be adjusted according to product specifications to meet the needs of different sizes.

4. Baking or Frying Equipment: bake or fry the molded sheet to make it crispy and delicious. These devices usually have temperature and time control functions to ensure the stability of product quality.

5. Filling Machine: Used to fill a variety of fillings (such as meat, vegetables, cheese, etc.) into the dough. The filling machine can be customized according to customer needs to adapt to the needs of different fillings and filling methods.

6. Burrito Forming Machine: Roll the filling pieces into the shape of burrito. The equipment has efficient rolling capability and precise dimensional control to ensure the appearance and taste of the product.

7. Packaging Machine: The production of good burrito packaging for storage and sales. Packaging machines can be customized according to product specifications and packaging materials to meet different market needs.

EXHIBITION

CERTIFICATIONS

PACKAGING & SHIPPING

BUSINESS PARTNER

COMPANY PROFILE

Anhui Jinke Foodstuff Machinery Co., Ltd.

Anhui Jinke Foodstuff Machinery Co., Ltd. is located in Hefei, the famous science and technology capital of China. Since its establishment in 2008, the company has been relying on the rich local high-tech talents and R&D resources to rise rapidly. We have grown into a professional bakery and food machinery solution provider serving Northeast Asia, Central Asia, Middle East, Eastern Europe and East Africa. We are committed to become the most professional bakery equipment and technical services company in the world. Anhui Jinke Foodstuff Machinery Co., Ltd. always focuses on the development of bakery industry with a global vision, and we constantly carry out strict control on the quality of products, and our products enter the European market, Central Asia, the Middle East, Africa, and Southeast Asia market countries and regions, and our customers are all over the world. The company relies on advanced equipment, accurate testing, senior development team, experienced senior technicians and passionate after-sales operation team. Guided by the enterprise spirit of "quality-oriented, service first", Anhui Jinke Foodstuff Machinery Co., Ltd. will, as always, focus on the research and innovation of the product technology and service of the production line of cake food machinary.

FAQ

Q1.How can I get a quotation?

A1.Send your requirements and attach your email ,your contract number,your company name & website,Our pre-sale engineer will confirm and reply you soon.

Q2.What's your payment term?

A2.Normally our payment term is 30% deposit and clear the balance before shipping .

Q3.What kind of payment method you is available?

A3.TT is available.

Q4.what's your lead time?

A4.Usually we will finish producing within 30 days after the deposit confirmed. But it is also depend on the feature of the order .If you need customization service,the producing time will be 60 days .

Q5.What kind of shipping method is available?

A5.By sea is better.

Q6.How do you control the quality?

A6.We are opening more than 16 years up to now,and we have a professional QA & QC team.

Q7.What's your machine guarantee?

A7.One year for the whole production line.

>>

Modern Bar Furniture Plastic ABS Bar Table (GT-09)

>>

International air transport of sensitive goods to the United States, freeze-dried powder, powder

>>

Automatic 3-10L big bottle water washing filling and screwing machine line

>>

Shear Metal Guillotine, Blade for Steel, Guillotine Shear Blade Bulkbuy

>>

JOHNCOO Lead Head Soft Fishing Lure 8.5cm 9.5g Artificial Soft Bait Long T Tail Lure Carp Crankbait with Treble Tackle Hooks

>>

inner Kraft paper moistureproof ad star welding valve laminated pp woven bag for packing cement

>>

2019 New 6-10 Person Inflatable River Boat/ Inflatable White Water Rafts/ Inflatable Drifting Boat

>>

Swj-16b High Speed Vertical Tapping Machine Metal Heavy Duty Cast Iron Steel Tapper Machine M16 M12

>>

Modern Hotel Bedroom Furniture Metal Bed Frame King Size Bed Frame

>>

Custom new fashion design track suit/ sweat pants

>>

Commercial frames solid wood engineered usa veneer hotel simple cheap prehung interior doors

>>

China Manufacturer Integrated Welding System Analog Ultrasound Transducer Generator Titanium Horn For Plastic Welders

>>

20kVA~3500kVA Yuchai Mtu Open Silent Soundproof Containerized Diesel Power Electric High Voltage Generator Set Genset Authorized OEM Factory

>>

Promotional Automatic CNC Swiss Type Automatic Turning Lathe CNC Turn-Mill Multitasking Machine

>>

Fruit Extract Apple Extract 5% 8% 10% Health Care Product Apple Cider Vinegar Powder

>>

Pet Preform Mold 24 48 72 Multi Cavity Preform Mold

>>

Warehouse Solar Powered Air Cooling Wall Exhaust Fan for Prefab House with No Electricity Cost

>>

RS232 dB9 9 Pin Female to 8 Pin Mini DIN Male Adapter PLC Programming Cable

>>

Colorful Pyrex Glass Oil Burner Skull Design Glass Tobacco Pipes

>>

Large One Door Catch Release Heavy Duty Cage Live Animal Trap for Gophers / Oppossums Groundhogs Beavers 32′′x10′′x12′′