|

US$28,500.00-182,000.00

|

1 Set

(MOQ)

|

Basic Info.

Processing Accessory

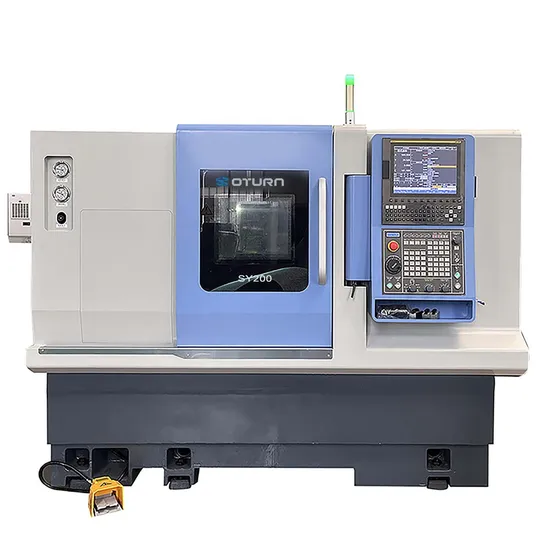

Chuck CNC Lathe

Guide Rail

Inclined Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Automatic Grade

Automatic

Certification

GS, CE, ISO 9001

Control System

Fanuc, Siemens, Mitsubishi

Motor Power

11,15,18.5,22kw

Transport Package

Plywood Case

Specification

2460x1800x1800

Production Capacity

1000/Year

Product Description

Product Description

The machine adopts an optimized 30-degree inclined structure design, which also has high precision, super rigidity and excellent cutting stability. High-strength HT300 cast iron one-piece solid structure lathe, using finite element analysis, the overall machine

It has excellent rigidity and stability, and can maintain long-term reliable accuracy, improve processing stability and tool life, and eliminate stress.

In addition to improving precision and stability, the high-strength roller linear rail design structure and the transmission system adopts screw pre-tension design to improve

Reflecting rigid performance, the simple and elegant appearance is in line with the trend.

1. Main features of this machine tool

1. Adopting a 30° inclined layout and an integrated structure of the bed base, which greatly improves the bending and torsional rigidity of the machine tool during operation. The high rigidity and high stability of the integrated bed base provide high precision for the entire machine. A strong guarantee.

2. The spindle unit is an independent sleeve type. The spindle system has undergone strict dynamic balance testing and has high precision, good accuracy retention, small thermal deformation, and good thermal stability. The maximum speed can reach 4500rpm, and the nose deflection accuracy is within 0.003MM. The front end of the shaft uses a large-diameter, high-precision double-row roller bearing with a combined angular contact ball bearing structure. The optimal span two-point balance support design can withstand radial and axial loads, and can also provide users with high-speed precision work. It can also perform low-speed and heavy cutting, and is especially suitable for mass production of products with complex shapes, high precision requirements, and high smoothness.

3. World-class high-rigidity overall design servo turret. Equipped with a high-precision clutch to ensure its positioning accuracy and repeatable positioning accuracy. It is equipped with a servo motor to drive the cutterhead to rotate for bi-directional or arbitrary tool selection. The hydraulic principle is used to loosen and clamp the clutch, and the proximity switch feedbacks the clutch action signal to quickly and accurately achieve the tool change action.

4. The machine tool is equipped with roller linear guides and ball screws. The heat-treated and precision-ground ball screws can ensure the best accuracy and durability. Each axis adopts a direct transfer axis structure and a double-anchor pre-relay method to ensure thermal stability. The amount of displacement is minimized,

greatly improving processing accuracy. The high-rigidity, large-sized, heavy-duty linear slide rails maintain intact accuracy when the machine is subjected to impact, and the displacement is smooth and low-noise, which can extend the service life. Product Parameters

| | Name | Unit | SY200 |

| Travel | Max. bed rotation diameter | mm | Ф600 |

| | Max. processing diameter | mm | Ф500 |

| | Max. machining rotation radius on the tool holder | mm | Ф260 |

| | Max. processing length | mm | 500 |

| | Distance between two tops | mm | 580 |

Spindle

Hydraulic Cylinder

chuck | Spindle nose | / | A2-6 |

| | Spindle through hole diameter | mm | Ф65 |

| | Max. rod hole diameter | mm | Ф52 |

| | Spindle maximum speed | rpm | 4500 |

| | Spindle direct drive motor power | kw | 22 kw |

| | Hydraulic cylinder/chuck | / | 8" |

| X/Z axis feed parameter | X/Z motor power | kw | 2.0KW |

| | X/Z axis travel | mm | 275/550 |

| | X/Z axis rapid movement | mm/min | 24 |

| | Positioning accuracy | mm | ±0.005 |

| | Repeat positioning accuracy | mm | ±0.003 |

| | Slide rail type | / | pin roller 35 |

Servo

Turret parameters | Tool head alignment/tool station | mm/pcs | 420/12T |

| | Outside diameter tool holder specifications | mm | 25x25 |

| | Inner diameter tool holder specifications | mm | Ф40 |

| | Adjacent tool change time | sec | 0.15 |

Tailstock

parameters | Programmable hydraulic tailstock | / | Protocol |

| | Max. travel of tailstock | mm | 360 |

| | Sleeve diameter | mm | Ф100 |

| | Sleeve stroke | mm | 100 |

| | Sleeve taper | / | MT#5 |

Outline

dimensions | Covered area approx. | m | 2.46x1.8x1.8 |

| | Mechanical weight approx. | kg | 4000 |

| | Cutting fluid tank volume | L | 103L |

| | Cutting water pump | kw | 0.75kw |

Products Configurations

Company Profile

Quality Control

Our Advantages

FAQ

Q1:How can l choose the most suitable machines ?

Please tell me your specications,we can choose the best model for you,or you can choose the exact model,you can also send us the products drawing,we will choose the most suitable machines for you .

Q2: What's your main products of your company?

We specialized in all kinds of machines,such as CNC Lathe Machine ,CNC Milling Machine,CNC Turning Maching,Vertical Machining Center ,Horizontal Machining Center,Lathe Machines,Turning and milling composite processing so on.

Q3: Where is our factory located? How can l visit there?

We have 5 factories located in Guangzhou, Quzhou, Ningbo, and Guangdong.You are warmly welcomed to visit us.

Q4. How do you transport it?

Provide Transportation Solution DDP/CIF/FOB/FCA

Q5: What's the Payment Terms ?

T/T ,30% initial payment when order,70% balance payment before shipment .

06: What's the MoQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

We want to know:

1.We strongly suggest you to tell us size, material of your workpiece for our evaluation if possible, better to send us workpiece drawing, so that we can recommend you most suitable model!

2.lf need ClF Price, please kindly tell us the port of destination.

>>

Recover Condensate for Boiler in Fishmeal Machine

>>

Double Row Sk150-33-047b Wheel Hub Bearing 35X65X35mm Gcr15 Chrome Steel

>>

Lanhao Intelligent Panel Bender for Stainless Steel

>>

LED Bulb 15W 4u Glass Cover LED Corn Lamp

>>

New Design Custom Plastic Beer Bottle Opener

>>

High Quality Chinese Modern Sliding Door Exterior Aluminum Folding Door

>>

China Top Selling Plastic Base Metal Frame Large Screen 8K Televisor 32 Pulgadas Smart TV

>>

Fuel Injection System suction control valve 294009-02302 for vauxhall astra

>>

Hygiene Equipment Elder Nursing Care Pad Underpad Manufacturing Machine

>>

GB/T32.1 Coarse Thread Hex Head Bolts With Wire Holes Locking

>>

Z94 series 5.5C 200mm length Fully automatic concrete iron nails making machine equipment

>>

OEM CNC Machined Collet Chuck Spring Collet for Hand Operated Tools

>>

Turbo 359-2121 Excavator Spare Parts Engine Parts Turbocharger for Hx30W 4bt3.9 Construction Machinery Parts

>>

Borehole Drilling Water Detector Surface Water Finder Mobile APP Underground Water Detector

>>

Two Blades, 6m Feeding Conveyor Drum Wood Log Tree Chipper for Biomass

>>

Wholesale Price Factory 3959612, P550774, Bf7817, 33697, Wk9306X, FF5580, FF5488 Fuel/Oil/Lube Filter for Fleetguard Cummins

>>

Aluminum/Aluminum 62FT Factory Made Pilot/Poiltvessel

>>

Wholesale 2 4 6 Bus Seat Power Battery Tourist New Mini Vintage Classic Club Trolley Hunting Sightseeing Buggies Utility Vehicle Offroad Electric Golf Cart EEC

>>

High Efficiency Huashil Sintered Stone Automatic CNC Cutting Machine with Optimized System Processing Machine

>>

Self-propelled Electric Scissor Lift Single and Double Work Platform