|

US$290,000.00-310,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Certification

GS, ISO 9001

Transport Package

Plywood Case

Specification

5800X5800X3600mm

Production Capacity

50 Sets/Year

Product Description

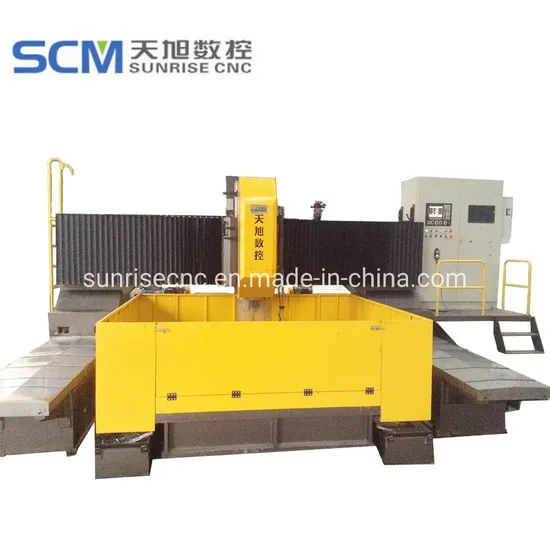

Applicable Industry: Mainly used for drilling tube plate, clapboard, flange and large plate in petrochemical, boiler, wind power, flange industries and also for connection plates in building, bridge, iron tower industries.

Product feature:

1. The lathe consists of lathe bed, work table, gantry, slide carriage, power head, CNC system, cooling chips discharge system etc.

2. The lathe works in mode of lathe bed and gantry being fixed and work table moving.

3. The lathe bed and gantry are weld assembly, work table is iron casting, which was high temperature annealed before processing, was annealed again after half finished machining to remove stress, then finished machining so that ensure stable precision.

4. The lathe has 3 numeric control axes; a heavy linear guide is equipped on the lathe bed. The work table can make longitudinal movement along the guide(X axis), the gantry cross beam has a linear guide too; the slide carriage can make lateral movement along the guide (Y axis). Sliders are equipped on the slide carriage, a guide on power head which can make vertical movement on the slide carriage.

5. The power head spindle is precision spindle of Taiwan KENTURN / Taiwan Xutai, which is driven by special frequency conversion motor and can make stepless speed regulation according to needs. The spindle is BT50 taper hole. The drilling head, reamer or milling cutter can be installed by splice bar. The spindle box has a loose cutter cylinder (air and hydraulic pressure) for easily changing cutters. It also can equip with cutter inter-cooled splice bar to realize high speed cutting.

6. The chip cleaner equipped at the back of work table can discharge chips automatically. The lathe use water cooling with the system of cooling liquid providing, recycling, circulating and filtrating.

7. Numerical control uses FAGOR8055 system, with RS232 connector and color LED panel, Chinese interface. It can make spot / external PC workpiece input and be easily operated.

8. Protective covers are equipped for X/Y axis guides and lead screw of the lathe. Iron sheet cover is for X axis, and organ-protective cover for Y axis.

9. For ensuring the reliability of the lathe, the key components use high quality imported products. See the main spare parts list for details.

Specifications:

| Parameter Name | Item | Specifications |

| Max. size | L X W | 5000X5000mm |

| Max thickness | | 250mm |

| Work table | Width of T slot | 28/500mm |

| Vertical slide type drill head | Quantity | 1 |

| Main spindle taper hole | BT50 |

| Max drill diameter(common carbon steel) | φ40mm(carbide drill) |

| φ50mm(HSS twist drill) |

| Main spindle speed | 30-2400r/min |

| Motor power of spindle | 22/33kW |

| Distance between spindle tip to work table | 300-800mm |

(X axis)

Gantry longitudinal move

| Max. stroke | 2000mm |

| Moving speed of X axis | 0-8m/min |

| Servo motor power of X axis/torque | 3kW/28.4Nm |

(Y axis)

Power head transversal move

| Max stroke | 2000mm |

| Moving speed of Y axis | 0-8m/min |

| Servo motor power of Y axis/torque | 3kW/28.4Nm |

(Z axis)

Vertical slider feeding | Stroke of Z axis | 500mm |

| Feeding speed of Z axis | 0-5m/min |

| Servo motor power of Z axis/torque | 3kW/28.4Nm |

| Positioning accuracy | X/Y axis | ≤0.1mm/ Full length |

| Repositioning accuracy | X/Y axis | ≤0.05mm |

| Hydraulic system | Hydraulic pump pressure/flow rate | 6.5MPa /25L/min |

| Hydraulic pump motor power | 3kW |

| Pneumatic system | Compressed air pressure | ≥0.4MPa |

| Chip cleaning and cooling | Chip cleaner type | Plate chain type |

| Chip cleaner no. | 2 |

| Chip cleaning speed | 1m/min |

| Chip cleaner motor power | 0.75kW |

| Motor power of inner cooling water pump | 3kW |

| Motor power of Outer cooling water pump | 0.75kW |

| Automatic lubricating system | Lubrication pressure | 2MPa |

| Lubrication point oil injecting amount | 0.1mL |

| Lubrication period | 6-10min |

| Electric system | CNC system | FAGOR8055 |

| CNC axis NO. | 4 |

| Whole power of motors | | Approx. 48kW |

| Overall size | LxWxH | Approx. 5800X5800X3600mm |

| Weight | Approx. 28t |

>>

Polyester Hi vis Work Wear Long Sleeves Shirt Custom High Visibility American Workwear Shirts

>>

Powder Metallurgy Sintered Bearings for Electric Fan Motors

>>

fish feed oil sprayer, oil sprayer for fish feed

>>

New Tech PSE-Pm Series 10m Polarized Reflection Laser Photoelectric Optical Proximity Sensor NPN PNP No Nc 12V 24V with CE UL

>>

CNC Machining Aluminium Belt Pulley and Flat Belt Pulley and Timing Pulley

>>

New Design Smart Counting Hula Ring Gym Home Fitness BT Music S Hula Ring Circle with Outing Flannel White Grey/pink blue

>>

China Manual brick machine Onnoh QTJ4-40 semi-automatic brick making machine

>>

mozzarella cheese processing machine cheese cooking vat

>>

Punch Tools, Punching Tools, Punching Tooling, Thick Turret Ultra B Station Complete Set Used in Punching Machines

>>

Elegoo Saturn 4 Ultra 16K

>>

Anti Wrinkle Facial Dermal Fillers for Removing Eyes Circle Tear Grooves

>>

Gear-Driven Petrol 170f Cultivator/ Mini Tiller/Power Tillers

>>

High Efficiency Wood Chips Hammer Mill Biomass Sawdust Hammer Mill

>>

High Frequency Large Capacity Pebble Limestone Vibrating Screen Construction Ore Washing Separator

>>

Ergonomic Modern Swivel Metal Gaming Computer Executive Leather Staff Office Chair

>>

New Type Hydraulic Release System Cone Crusher

>>

600PCS/H Best Selling Automatic Chapati Roti Baking Cooling Stacking Pressing Laminating Food Machine Supplier Factory Price Customized Production Line

>>

Tetra Sodium Pyrophpsphate (TSPP) Industrial Grade Drum

>>

German Type High Quality Combination Pliers, Nickel Iron Plated

>>

Pulse Magnetic Therapy Device For Erythrocyte Aggregation Rehabilitation And Full Body Blood Circulation