|

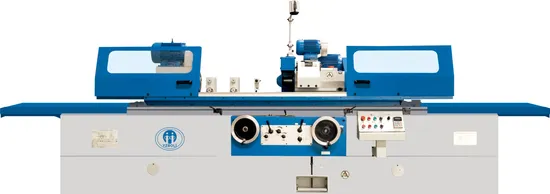

US$6,000.00-10,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Automatic Grade

Semiautomatic

Cylindrical Grinder Type

Surface Grinder

Certification

GS, CE, RoHS, ISO 9001

Product Name

Grinding Machine

Control

Manual/Semi-Auto/Auto

Table Type

Normal-Table/Magic-Table

Transport Package

Iron Pallent with Plastic Cover

Product Description

| table size W*L | mm | 150*450 |

| max grinding size W*L | mm | 160*470 |

| max distance from table to spindle center | mm | 450 |

| magnetic chuck size (optional equipment) | mm | 150*400 |

| stroke of table left and right motion | mm | 500 |

| stroke of table cross motion | mm | 185 |

| feed of elevating handwheel | mm | |

| div | mm | 0.005 |

| rev | mm | 1 |

| grind wheel size | mm | 200*13*31.75 |

| spindle roating speed | r/min | 2850(50HZ) |

| power of spindle motor | kw | 1.1 |

| machine weight | kg | 750 |

| package size(worktable dismantled) | cm | 1350*1110*1950 |

The grinding machine is a versatile and efficient tool used for various applications in the manufacturing industry. It is designed to remove excess material or shape workpieces with precision and accuracy. The machine utilizes an abrasive wheel or belt to achieve the desired result. One of the key advantages of the grinding machine is its ability to produce a smooth and polished finish on different materials, including metals, plastics, and ceramics. This makes it ideal for tasks such as surface finishing, deburring, and sharpening tools. The machine's operation involves rotating the abrasive wheel or belt at high speeds, which creates friction against the workpiece. As a result, the excess material is gradually removed, and the desired shape or finish is achieved. The grinding machine can be operated manually or automatically, depending on the complexity of the task. In addition to its versatility, the grinding machine offers excellent precision and accuracy. It is capable of achieving tight tolerances and fine surface finishes, making it an essential tool for industries such as aerospace, automotive, and medical. Furthermore, the grinding machine is designed for durability and reliability. It is built with high-quality components and features a robust construction to withstand the demands of heavy-duty applications. Overall, the grinding machine is an indispensable tool in the manufacturing industry. Its ability to remove excess material, shape workpieces, and produce smooth finishes makes it a valuable asset for any production facility.

>>

Spring Summer 2024 New Soft Soled Flat Sandals Women Fashion Elastic Light Sandals

>>

Full automatic paper hard board production line

>>

High quality 8 person electric golf cart sightseeing bus commuter shuttle bus

>>

Hengpeng Shipyard Bucket Wheel Dredger with High Efficiency and Reliability

>>

Multi-Purpose Pliers Knife for Outdoor Portable Toothe 16 in One Multifunctional Tool Outdoor Pliers

>>

Wholesale Peanut Combine Harvester Groundnut Harvesting Machine Peanut Picker Fresh Peanut Picking Machine

>>

Plywood Assembly Line for Making Furniture Board

>>

Electric Concrete Batching Plant 50m3/H to 240m3/H Small Portable Concrete Batching and Mixing Plant

>>

Industrial 380VAC Power 15KVA 30KVA 60KVA Servo 3 Phase Automatic Voltage Stabilizers

>>

Automatic round square bottle self adhesive sticker double-sided labeling machine for packaging water filling line

>>

EVA Pouring Mould for Double Color Sole

>>

Windbreak Car Parking Outdoor Dark Green Anti UV Sunscreen Plastic/PE Garden Fence Sun Shade Mesh Net Price

>>

Ce Certificate Automatic Plastic Crushers Knife Blade Grinding Machine

>>

2023 Popular Selling Agricultural Tracked Transport Vehicle

>>

New Arrival Front Rear Car Bumper For Mercedes CLS 19-21 W257 C257 Upgrade AMG-GT63S Body Kits Rear Diffuser With Exhaust Pipe

>>

Bathroom Hanging Shower Organizer Over Head Shower Caddy Basket with Hooks for Razor and Sponge

>>

ne8.5s black gloves yarn to Russian market

>>

Fashion High Quality Design Embroidery Lace Fabrics for Party Dresses

>>

Bright Dimmable LED Strip for Home Decoration

>>

Amazon Hot Sale Magnetic Fridge Spice Rack Organizer Refrigerator Metal Wall Side Hanging Storage Rack