|

US$5,000.00-15,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Type

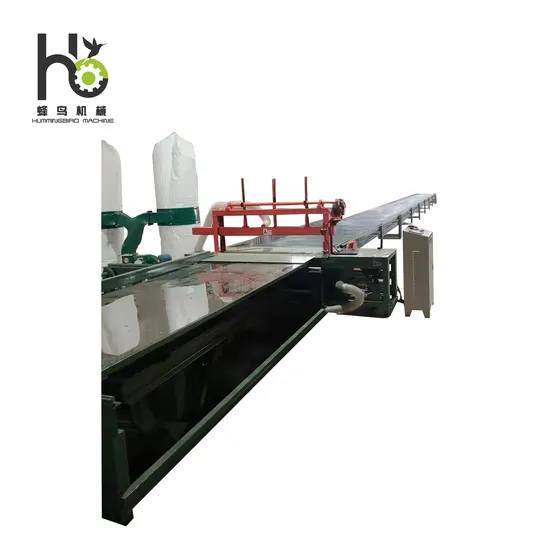

Plywood Assembly Line

Working Board Size

1220*2440mm

Transport Package

Container

Specification

Customized size

Product Description

The plywood assembly line is an important equipment in the plywood production process. It is mainly used to lay the glued veneer into a slab in a certain order and manner to prepare for subsequent hot pressing and other processes.

Improve production efficiency: The laying line can realize automated production, greatly improve production efficiency and reduce labor intensity.

Ensure product quality: Through precise control and automated operation, the laying quality of plywood can be guaranteed, and the consistency and stability of products can be improved.

Reduce production costs: Automated production reduces labor costs, while improving production efficiency and reducing production costs.

Adapt to diversified production: The plywood assembly line can be adjusted and changed according to different production requirements and product specifications to adapt to diversified production needs.

Company Profile

Shandong hummingbird Machinery Co., LTD, located in Linyi city, Shandong province, has more than 20 years of experience in machinery production and improvement.The company established Hummingbird International Trading Company in order to expand the international market. After several years of efforts, the company's main products and equipment have been exported to Southeast Asia, the Middle East, South America, Africa and other markets.Looking forward to working with you to create, share the future!

Product Parameters

| Model | HB-PZ0012 |

| Working board size | 1220*2440mm |

| Lay-up head size | 3000*1580*1150mm |

| Working table | 25m |

| Conveyor speed | 5-10m/min |

| The cutting way | SaW |

| Loading style | vertical down |

| Control type | PLC control |

| Total power | 13.5kw |

| Weight | About 5 Ton |

Features

Single board conveying: convey the glue-coated single board to the designated location according to production requirements through belt conveyors, chain conveyors and other devices.

Laying and forming: on the paving table, lay the single board layer by layer in a certain paving method to ensure the quality of the single board.

Slab conveying: convey the paved and formed slab to the next process, such as the hot press for further processing.

Full Service Process

About service

Pre-sale service1.Provide the free consultation of equipment

2.Provide the standard device and the flow chart

3.According to the clients' special requirement ,offering the resonable plan and free design to help to select the equipment .

4.Welcome to visit our factory

Service during the sales1. Inspect the machine before leaving the factory

2.Oversea install and debug the equipment

3. Train the first-line operator

After sales service1. 24 hours online service

2. Provide the VIDEO with install and debug the equipment

3. Provide technical exchanging

Why chose us

1.lasering your logo on products and designing logo is free2.Delivery time within 30days3.No else charge4.MOQ≥15.Provide products quotation6.Provide Packaging customization service7.SupportWechat/Email/whatsapp/8.We specializein this field for 25 years9.Excellent after-sale system10.Supporting visits to factory

FAQ

1.Q: Factory or distributor? A: We are A manufacturer of wood-based panel machinery. Our products are manufactured by our own manufacturers and technical experts.2. Q: Quality control? A: Each machine is tested three times before delivery. 3.Q: Lead time? A: 30-40 days after receiving the deposit.4. Q: Factory layout design? A: We have A team of engineers making floor plans for customers for free.5. Q: After-sales service? A: We have technicians to help customers with the installation.6. Q: Warranty? It's a one-year warranty, and we always provide parts and service.7. Q: Terms of payment? T/T or L/C will do.8. Q: behind MOQ? A: The moQ is 1 set.

>>

Customized DOT Approved Modular Flip up Motorcycle Helmet with Sun Shield

>>

Fanuc ac servo motor A06B-0205-B300 for cnc milling machine Fanucworld

>>

Wisdom Portable Automatic Diamond Wire Saw Machine for Landscape Rock Wall Monument Limestone Stone Block Cutting Machine

>>

High Wear Resistance Corrosion Resistance Customized Precision Die Cast Mould

>>

Suitable For Tesla Model 3 Front Bumper Engine Lower Guard Plate Auto Parts 1084174

>>

Farm Agriculture Machinery Cultural Tiller Disc Harrow Plough Plow Discs Disker Blade Disc Plow

>>

3507205 Presser foot for Yamato sewing machine VG2735P-32 sewing spare parts

>>

American Standard Hurricane Proof Heat preservation Impact Rated aluminum bi folding windows

>>

6CT8.3 Piston Four matching piston assembly 3631246 3907156 3907163 3917707 3919564 3919565 3923537

>>

Customized Anti-Oil 2mm PVC Curtain Roll Transparency Anti-Fire Heat Resistant Welding Plastic Curtains

>>

Multi-Layer Coated N25/N35/N42/N52/Rare Earth/Block/Round//Round/Block/Ring/Arc NdFeB Permanent Disc Magnet for Marine/Automotive High-Temperature Disc Magnet

>>

Measurement Active Electronic Inline Measures Pulp Transmitters Pneumatic Blade Consistency Transmitter

>>

Hmc Servo Motor Horizontal Machine for Case Part/ Automotive/ Medical Instruments

>>

High quality black painting aluminum perforated metal

>>

Plastic Extrusion 20L/25L/30L Chemical packaging Jerrycan Accumulator Die Head Blow Molding Machine/Made in China

>>

Myk1224 High Precision CNC Hydraulic Surface Grinding Machine

>>

Center Console Panel For 2021 Tesla Model 3/Y Protective Cover Water Cup Holder Center Armrest Covers

>>

High Capacity and Adjustable Fineness Ultrafine Grinder

>>

PCD CNC Nesting Router Bits Polycrystalline Diamond Cutters Z=3+3 Diamond PCD Compression Spiral Router Bit

>>

Customized Logo 3D PVC kids funny fashion photo frame,pvc frame picture rubber 3d baby 12 month photo frame