|

US$900,000.00-4,500,000.00

|

1 Set

(MOQ)

|

Basic Info.

Model NO.

lightweight cement block production line

Capacity

50, 000-300, 000cbm/Year

Transport Package

Stand Seaworthy Packing

Specification

CE, ISO, SGS

Production Capacity

50, 000-300, 000cbm/Year

Product Description

Product Description

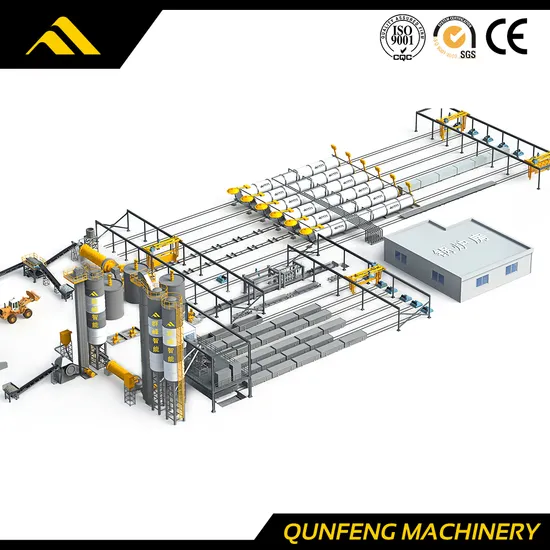

Features

(01)Belt Conveyor (02)Batching Machine (03)Roller Screen (04)Grinding Head Silo (05)Wet Ball Mill (06)Jaw Crusher

(07)Dust Catcher (08)Bucker Elevator (09)Silo For Coarse Lime (10)Dry Ball Mill (11)Silo For Fine lime (12)Cement Silo

(13)Screw Conveyor (14)Slurry Storage Tank (15)Weighing Hopper For Slurry (16)Weighing Hopper For Lime And Cement

(17)Ferry Cart (18)Turning Crane (19)Vertical Cutting Machine (20)Horizontal Cutting Machine (21)Turning&Grouping Crane (22)Curing Cart (23)Autoclave (24)Finished Product Crane (25)Block Clamping Machine (26)Winch For Side Plate Return Technological process: 1. First, dose and match measured raw materials; 2. After distributing, feed raw material into pouring mixer to make slurry. 3. Through thoroughly mixing, the slurry is poured to mould; , 4. After pre-curing under a certain temperature and time, the block would reach a certain hardness and prepare for cutting; 5. Tilting hoister would turn over 90 degrees of mould; 6. Then open the mould and separate it from block. And take the block with side plate to the cutting cart; 7. Firstly, the cutting machine vertical cuts blocks from both sides. 8. Secondly the horizontal cutting; 9. Finally the vertical cutting; 10. After cutting, the block is hanged to trolley with side plate by semi-finished product hoister; 11. Organizing the cut blocks and put them into autoclaves; 12. Hardening the blocks under certain temperature and pressure; 13. Carry the finished product out of autoclave 14. The finished product hoister take the finished product to stock shield; 15. Packed for loading; 16. The side plate return back through side plate roller; 17. Side plate would be organized with open mould; . 18. Clean the mould and prepare for next pouring; 19. Steel bars processing line for slab production.

Customer Case

About us

Sales Team

Main Products

Application Case

CERTIFICATE

Packaging & Transportation

>>

Hot Sale 1 Ton Mini Excavator Hydraulic Crawler Micro Digger

>>

Custom Wholesale Outdoor Pickleball Net for Outdoor and Indoor 22 Feet Net with Steel Portable

>>

Flower Canvas Wall Art with Hand-Painted Texture Oil Painting

>>

Aluminum Profile Smart Switch Roof Windows Large Scale Electric Motorized Opening Sliding Skylight

>>

N a n, adaptador Coaxial, conector de doble enchufe.

>>

High Quality Mini Wheel Bucket Sand Washer Washing Machine Sand Washer

>>

Unlocked Used Mobile Phone 5g Smartphone Phone14 PRO Max 128GB Cell Phone 2025 Wholesale Smart Mobile Telecon

>>

American style Upvc profile upvc window horizontal Single sliding windows glass glazed sash

>>

Bathroom accessories Set Toilet Brush Holder Soap Dispenser Tumbler Soap Dish linear Shape Concrete with Color Coating

>>

50pcs/Box Kid Face Mask 3 Ply Ear Loop Non woven Disposable FaceMask Protective Face Mask For Children

>>

China Factory Dob IC 100-265V 3W 5W 7W 9W 10W 12W LED Bulb Light

>>

Wholesale Bench High Precision Lathe M Series Turret Milling Machine

>>

OGM series Flow Meter Electronic Fuel Oil Flow Meter Suppliers High Viscosity Flow Meter

>>

PVC Plastic Pellet Making Machine

>>

Wholesale 16-Inch Gaming Laptop with Intel Core I7/I9 Processor, 16GB RAM+512GB Storage, and Nvidia Geforce Rtx 4060 Graphics Card

>>

Automatic Herbal Leaves Grains Pulverizing Spice Pepper Pulverizer Moringa Powder Grinder Machine for Food

>>

Long Cotton Interlock Liner PVC Coated Work Gloves

>>

Promotional Top Quality New Design Large Capacity Laminated PP Woven Shopping Bag

>>

Custom Laser Cut Gates Perforated Garden Gates Decorative Aluminum Fence Rusty Corten Steel Metal Gates Garden Trellis

>>

± 1º C Temperature Accuracy FRP GRP Pultrusion Equipment China Suppliers Plastic Machine FRP/GRP Products Pultrusion Equipment