|

US$40,000.00-90,000.00

|

1 Piece

(MOQ)

|

Basic Info.

Model NO.

QX500 QX1000 QX2000 QX3000 QX5000

Computerized

Computerized

Certification

ISO9001:2008, CE

Suitable Material

Post Consumer Film, Agricultural Film, Woven Bag

Output Capacity

150-1000kg/H

Motor Brand

Siemens, Weg, Sew

Controller

Siemens PLC or Button Control

Material

Stainless Steel SUS304

After-Sale Service

Engineers Available to Service Machinery Overseas

Process

Shredding, Crushing, Washing, Drying

Electric Components

ABB, Ls, Omron, or Customized

Transport Package

Plastic Film and Wooden Pallet

Origin

Zhangjiagang, China

Production Capacity

30 Sets/Per Year

Packaging & Delivery

Package Size

200.00cm * 200.00cm * 200.00cm

Package Gross Weight

4000.000kg

Product Description

Applicable Material:

PE/PP bottles, Drums, Lumps, Pipes, Basket, Crates, household bottles, plates etc.

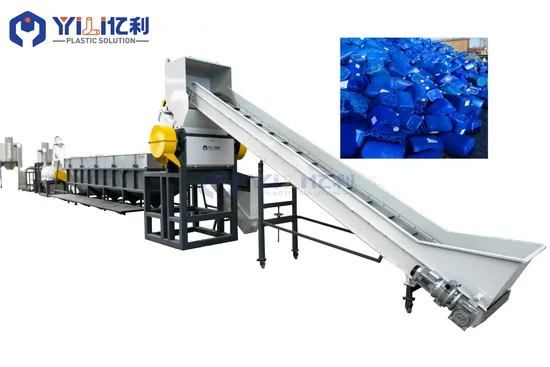

Introduction

The waste hard plastic recycling and washing line produced by YILI Machinery can treat various kind of hard plastic material, such as PE or PP bottles, IBC tanks, pipes, lumps, flakes, jugs, blocks, die head material, etc. The whole production line includes shredder, crusher, frication washer, floating tank, centrifugal dryer, etc, which have capacity from 300 to 5000 kg/hr. Our hard plastic washing line can assure a precise and efficient decontamination of waste plastics with both cold and hot washing system, adopting the most efficient recycling technologies. The final products after washing can reach very high quality, which can be used alone or blended with other materials into reprocess.

Technical Parameters

| Model | Capacity (kg/hr) | Power installed (Kw) | Water consumption (ton/hr) | Manpower |

| HQX500 | 500 | 160 | 0.5 | 3 |

| HQX1000 | 1000 | 220 | 1.2 | 3 |

| HQX2000 | 2000 | 350 | 3 | 4 |

| HQX3000 | 3000 | 410 | 4 | 4 |

| HQX5000 | 5000 | 500 | 5 | 6 |

Tech Features & Advantages

The whole production line is automatic controlling, compact process, high production efficiency, and nice cleanness; This line can separate muds, sands and other impurities from films and bags easily; With pre-treatment system such as Pre-washer, Label processing, it can highly improve quality of end product; Provide high capacity of dewatering machine with one machine capacity with 5000kg/hr Typical design of floating tank ensure not only cleanness of washed material, but also easy discharge of dirty dust by hand valve or pneumatic valves; Easy maintenance, low energy consumption, long lifetime.

Main Machines For the line

Belt conveyor

Both light and heavy duty type of belt conveyors can be chosen. Adopt gear box motor, with side walls to avoid material dropping. It has the option to install metal detector on the belt conveyor.

Shredder When the raw material is big, like plastic big drums, tanks, Lumps, die head material, we will choose shredder to make the preliminary grinding. After preliminary crushing, the material will go to second time crusher to make mine crushing. The final material sizes will be less than 12mm, which is better for pure cleaning. YILI supply series type of shredding with various capacity and functions to meet customers' choices.

Crusher

Crusher is to crush material into smaller sizes. It is with water to clean material and cool blades during crushing. Large materials are processed into small pieces in this module, which improves the washing result and makes the final product easy to packing.

Frication Washer The frication washer is designed to wash the plastic in high speed with water, which can help to remove the contaminations, dirties, greases on the material efficiently. After frication washer, the material can go to floating tank for more cleaning.

Floating tank

The sediment and metal in the material can be effectively separated through this module. All the washing wheels with different designs to meet the washing function, speed with inverter control. Bottom with magnetic valve to discharge the dirties timely according to set. Material: stainless steel.

Centrifugal Dryer Horizontal type of centrifugal dryer dry plastic flakes with high performance and low energy consumption. The grid mesh is with self-washing function by timer setting. It offers both washing and drying for material.

Hot air pipeline heating

Pipeline built in stainless steel, giving hot air inside to make further drying for material, decrease the moisture inside material.

>>

Low cost 1 ton 2 ton big bag jumbo bag

>>

5L (Single station & Three head) Blow Moulding / Molding Machine

>>

Hy5039 Chrome Polish Sanitary Ware ABS Plastic Overhead Shower Head

>>

China High Quality 60 Cbm/H Drum Mixing Plant Mobile Concrete Mixing Plant Yzg60

>>

DDP Delivery Air Freight Shipping Agent to Europe, USA, Canada, Australia

>>

Pet Preform Injection Plastic Mould Pet Test Tube Mould Injection Mold Making

>>

Pet food fiber desiccant sheet eco friendly for dog cat food nuts rice

>>

CE Tz-11 Series 4 Wheel Tractor Mini 4 in 1 Front End Loader Can with Dozer Blade Forklift Snowblower Backhoe

>>

Hot sale custom reusable hot cold pack

>>

10-20t/H Szlh508 Animal Feed Pellet Mill Machine

>>

Autool Upgraded Sdt206 Car Smoke Leak Detector Professional Auto Pipe Leak Detect Tool for Cars Motorcycles

>>

Forest Fire Detector Solar Field Fire Monitoring Equipment

>>

15t/H Poultry Feed Processing Plant Cost/Poultry Feed Mill

>>

ST-039 / Silicone Kitchen Tools Set

>>

High Precision Machinery Lathe Lh6260*2000mm Manual Metal Turning Machine with Quality

>>

HC-R028 Veterinary Portable Flexible endoscope video camera endoscope for Gastroscope and colonoscope for small animals

>>

Built-in Luxury Massage Bubble Jet Whirlpool Bathtub

>>

Pl/MB/Dat10/Dt10 Conveyor Rubber Timing Belt for Manufacturer Assembly Line

>>

Steel LPG Gas & Tank Cylinder-9kg

>>

Good Price 1t 2t 3t 5t 10t 15t 20t 30t 50t Hook Trolley Low Headroom Type Electric Chain Hoist with High Quality for Factory