Basic Info.

Model NO.

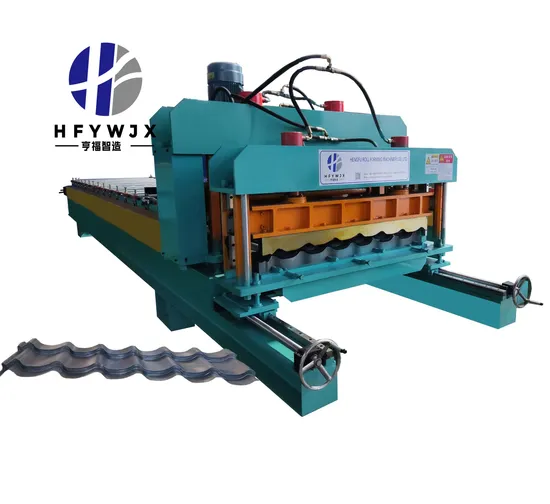

1100glazed tile roll forming machine

Transmission Method

Electric

Transmission Mode

Chain Drive

Cutting Method

Linear Guide Rail Shear According to The Shape

Transport Package

Plastic Film & Steel Wire Fixed

Specification

9000mmx1800mmx1700mm

Origin

Dongguang, Cangzhou City

Production Capacity

400sets/Year

Product Description

Product Description

| Model NO | 1100 |

| Condition | New |

| Usage | Roof |

| Feeding Width | Feeding Width |

| machine frame | 350H steel frame |

| Forming Speed | 4-5M/min |

| Color | Custimized |

| Type of Driven | Chain drive |

| Transmission Method | Electric |

| Number of rolling mill sets | 16 row molding |

| Spindle diameter | Φ70mm(Solid shaft) |

| Customized | Customized |

| Feeding method | Double hand rocking feeding rack (with pressure roller) |

| Specification | 9000mmx1800mmx1700mm |

| Electrical Control System: | Industrial Computer PLC |

| Origin | Cangzhou, Hebei |

| Warranty | 1 year |

| Transport Package | Plastic Film & Steel Wire Fixed |

| HS Code | 8455221000 |

The roller table forming part of the 1100 partial arc roll forming machine is driven by a motor, and the chain drives each roller to rotate. In the pressing part, a hydraulic cylinder drives the mold to move up and down, which can press the colored steel into many sections, shaped like glazed tiles. The cutting knife part of the 1100 type arc Glazed Roll Forming Machine is driven by a hydraulic cylinder to move up and down, which can cut off colored steel tiles.

The antique glazed tiles rolled by the 1100 type partial arc equipment and die-formed have the characteristics of beautiful appearance, simple and elegant, unique shape, taste, etc., and can be widely used in garden-style factories, tourist attractions, pavilions, hotels, villas, exhibitions Buildings and outdoor decorations such as hotels, resorts, homes, etc.

| Raw materials | Galvanized steel plate, color steel plate |

| Machine frame | 350H steel frame |

| Feed width | 1200mm |

Pattern diagram:

Detailed Photos

1. Framework: 350H steel frame

2. Number of rolling mill units: 16 rows for forming

3. Roll material:45 # steel rough lathe fine lathe outer circle grinding and electroplating treatment

4. Spindle diameter: Φ 70mm

5. Feeding method: Double hand rocking feeding rack

6. Cutting: Cut after molding, hydraulic double linear guide rail follows the cutting pattern

Workshop

Packaging & Shipping

Company Profile

Hebei Hengfu Roll Forming Machine Co., Ltd. is a professional manufacturer of cold-bending forming equipment and its complete set of automated production lines. With advanced production equipment and product development and design capabilities, the products are at the leading level in the industry with the advantages of high rate, high precision, high flexibility, and low processing loss, and the products are favored by industry customers.

Our company's main products include: color steel plate equipment, glazed tile equipment, floor decking equipment, CIZ steel forming equipment, composite sandwich panel assembly line equipment, car compartment panels, dust removal anode plates and other equipment. We can design and manufacture special models according to user requirements, provide users with technical guidance, production installation, commissioning, and after-sales one-stop service.

In recent years, a large number of products have been sold to more than 50 countries and regions including Russia, India, the United Kingdom, Australia, Kazakhstan, etc., and have been well received by customers at home and abroad.

Certifications

FAQ

Q:- Are you a manufacturer?A:Yes absolutely. Welcome a lot for your visiting to us.Q:- What's the delivery time?A:Normaly will take 45daysQ:- What service can you provide before order?A: About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price,payment terms, ect.If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.Q:- Can you finish the machine during the delivery time?A: We will finish the machine in time according to determined lead time.Q:- Do you have after-sale support?A:Yes, we're always here for giving you advice and support for technical details since we have senior technician. Q:- Any other service?A: We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

>>

Ewaste PCB Recycling Plant | PCB Board Scrap Recycling Machine for Sale

>>

Environmental RTV Weatherproof Alcohol Type General Purpose Neutral Silicone Sealant

>>

Us Air Force USAF Sunscreen Visor Hats Empty Top Baseball Cap

>>

China Huajin Welding Equipment Good Quality with ISO9001: 2008 315mm

>>

High Quality Personalized Crystal Acrylic Remembrance Decorations Sympathy Gifts Multiple Shape Love Valentine′s Day Gifts

>>

Hotsale Wooden Church Seats Theatre Cinema Seats Schoo Conference Hall Auditorium Chair (YA-08B)

>>

Custom Shape Briquette Press Supplier in Germany

>>

USB Rechargeable Electric Portable Power Sprayer Gun for Garden Use

>>

JohnDeere Farm Agriculture Machinery Tractor Parts

>>

Digital Satellite Finder Signal Meter for Satlink Ws-6933 Vf-8900 Ws-6966 DVB-S2

>>

High Strength Custom Flat Coil Springs Stainless Steel Spiral Constant Force Power Spring

>>

Ceramic Road Stud, Road Marker Kt-401

>>

australian standard aluminum windows models Industrial Aluminium Casement Windows

>>

420 375 340 HP engine hand pump D5010412930

>>

Cubierta de zapato desechable high quality non-woven shoe cover affordable

>>

CNC Duplex Milling Machine-Belt Type-Double Head Face Millinig-Double Sides Surface Milling

>>

Automatic 2 Color Bottle Screen Printer CNC02

>>

Comprehensive CNC Machining for Various Materials and High Precision Quality Certification Custom Machining Services

>>

PE Series Graphite Processing Machine, Graphite Crusher

>>

Roller pressing chicken manure/cow dung/ and fowl dung fertilizer pellet making machine