Basic Info.

Model NO.

IB-ST-1625-SLTY

Certification

CE, ISO 9001:2000, ISO 9001:2008

Application

Leather, Fabric

Applicable

Leather, PVC,Rubber,Foam,Sponge,Composite Material

Machine Type

Oscillate Knife

Cutting Thickness

0.1- 30mm(Depending on Material)

Transport Package

Woodcarton

Production Capacity

3000sets

Product Description

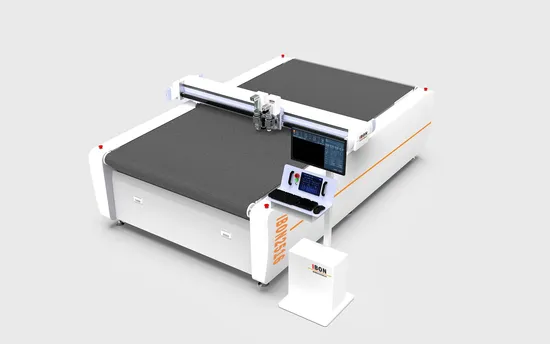

Automatic Oscillating Knife Cutting Machine & Leather Cutting Machine

Knife cutting machines for soft and light materials ,cutting of various flexible materials such as automotive interiors, leather seats, leather, sofas, carpets, clothing, shoes, advertising supplies, cardboard, wool blankets, fur, soft glass, toys, bags, printing and packaging, composite materials, etc

Applicable cutting materials: different kinds of materials,such as PU leather,PVC,foam composite material, soft glass, embroidery accessories, XPE,coiled mats, silicone, rubber, truck tarpaulin, gasket,etc

| Machine Parameters: Automatic Feeding Model NO. 1625 |

| Model | IB-A2-1625Automatic Feeding |

| Cutting Range | 1600mmX2500mm |

| Size | Approximate Size 2200mmX3500mm |

| Max. Cutting Speed | 60-2200mm/s |

| Minimum Cutting Circle Diameter | 5mm |

| Input Buffer | 128MB |

| Max.Cutting Thickness | 60MM (According to the material) |

| Cutting Accuracy | ±0.1mm |

| Repeat Accuracy | ±0.1mm |

Automatic cutting and automatic defect identification,Cutting cost High precision, high efficiency, time and labor saving,Automatically identify defects, reduce scrap rate and save time and effort

Machine advantages:

Unique multi-partition technology, adsorption capacity increased by more than 5 times.

Super nesting master software, material utilization rate increased by more than 10%.

Independent research and development of industrial vision system, to achieve special-shaped printing material cutting

Taiwan linear guide rail transmission system is selected, and the accuracy ±0.1mm

With the Japanese Panasonic servo system, the production efficiency has been increased by more than four times

Differentiate the grades according to the leather, support division and classification multifarious nesting cutting.

Quick tool exchange system for easy cutting of a wide range of hardware and soft materials More than 500,000 labor and raw materials are saved every year

Selected industrial vision system, quickly scan of leather, automatic identification of shapes and defects.

This model has won 8 technical patents at home and abroad

>>

Wholesale Fabric Textile Synthetic PU Leather PVC Rexine Artificial Microfiber Shoe Materials

>>

OGM series Meter Gear Liquid Flowmeter Oval Flow Meter Japan Digital Diesel Fuel Flow Meter

>>

2024 Environmentally Hotsale Luxury Walking Bike Stroll Bicycle Electric Car Treadmill

>>

Carbon fiber strips bars 5x20mm Carbon Fiber Flat Strips Fiberglass Strips

>>

Automatic Animal Feed Pellet Making Line

>>

Simple Silver Jewelry Blue Topaz Square Manin Stone Bracelet Fashion Jewelry

>>

Lubricant Additives Blending Machine Lubricant Additives Making Machine

>>

Hotel and travel wholesale disposable toothbrush with toothpaste

>>

40kVA 30kw 380V 430V 500V Variable Transformers Variacs Tsgc2j Contact Voltage Regulator

>>

Portable Pop Style Manufacturer Sells Painless Crystal Hair Eraser Stone

>>

18K Lab Diamonds Ring and Yellow Diamond Dual Purpose Ring and Pendant

>>

261815140102 TATA Engine Starter Motor for Cars 24V

>>

PVC modern white frame folding door sliding door lowes glass interior folding doors style

>>

Ployester Jacquard Mermaid Flannel Fleece Fabric for Pajamas Toy and Baby Blanket

>>

Table Biscuit Machine for Home Baking and Chain Bakery Shop Equipment

>>

Automatic Maize Peeling Corn Sheller and Thresher Machine for Sale

>>

Big Screen Anti-Glare All in One Touch Display Interactive Smart Teaching Education Flat Panel LCD Digital Whiteboard

>>

365nm 385nm 395nm 405nm UV-LED UV Light Lamp for Curing

>>

Vm1585lm High-Precision CNC Lathes and Milling Machines with Factory Direct Pricing and Quick Shipment Vmc CNC Machine Center

>>

Automatic Chocolate Bar Biscuit Cake Feeding Flowing Packing Machines Food Wrapping Machine Packaging Line Paketleme Makinesi