Product Details

Product Description

Product Description

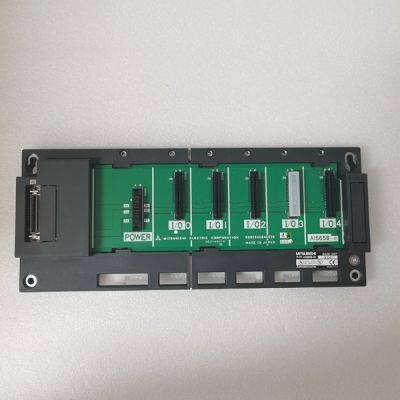

Brand:MITSUBISHI

Type:A1S65B-S1

Origin:the United States

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts of our products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

EMC COMPLIANCE WITH EN61800-3 Use in a Domestic Environment WARNING The products covered in this manual are of the restricted sales distribution class according to IEC 61800-3. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures. CAUTION Because applications differ, it is impossible for the drive manufacturer to guarantee machine EMC compliance. In some applications, it may be necessary for the machine builder to incorporate more EMC mitigation techniques than Danaher Motion had to use in the EMC test setups. General Suggestions to Improve Machine EMC Performance Use Danaher Motion cables – Danaher Motion cables have been designed with EMC considerations in mind. Because subtle differences in cable construction can cause dramatic changes in EMC performance use of Danaher Motion's motor power and feedback cables is recommended. When joining or splicing sections of cable, be sure to maintain the integrity of the cable shield along the entire length of the finished cable. Separate cables according to type - AC Mains input, motor power and signal cables should be separated from each other by at least 100 mm (4 in) to avoid cross coupling between them. If cables of different types have to cross, they should do so at a 90° angle. Route wiring close to machine frame - It is a good practice to run wires along the machine frame (local ground) whenever practical, this couples some high frequency noise/signals that could otherwise be troublesome directly to the local ground. Remove paint from all drive, filter, and cable clamp mounting locations. Add clamp-on ferrites to cables – Adding clamp-on ferrites to noisy cables can reduce emissions by absorbing RF energy before it is radiated. Use the appropriate line filter – A line filter is required for CE applications, more information on line filter selection can be found in D.10 Add a balun to the motor power cable – adding a balun in series with the U, V and W phases of the motor power cable can attenuate both conducted and radiated emissions. Ensure that cables shields have a good RF ground – more information on this can be found in D.10. G.10 AC MAINS CONDUCTED EMISSIONS Line Filter To meet the CE-conducted EMC requirements, an external line filter (in series with the AC mains) is necessary. It is the responsibility of the machine builder to choose filter(s) appropriate for the application. Danaher Motion is willing to assist in this choice. Often, the decision is made to filter the machine as a whole instead of filtering the individual drives. Mount the line filter as close as possible to the point where incoming power enters the machine/cabinet. Locate the drive(s) as close as possible to the line filter. To provide maximum high frequency filtering, remove any paint from between the filter, the drive and the conductive surface, ground plane to which they are bonded. For maximum benefit, separate input wiring to the line filter and output wiring from the line filter from each other. During CE testing, multiple line filters were qualified for use with 50 m motor and feedback cables to represent worse-case, conducted emissions compliance. The below lists filters used during CE testing. Match filter rating to drive input ac ratings for proper combinations. Corcom 6EQ1 (single phase) Corcom 36FCD10 (three phase) MTE RF30006-4 (three phase) Schaffner FN258-7, FN258-16, FN258-30, FN3258-16, FN3258-30 (three phase)

>>

7000btu 9000btu 12000btu R410a Eco-Friendly Mini Air Conditioner Portable Home

>>

Flexible, Thin, Lightweight Artificial Exterior Wall Decoration Flexible Stone Wall Tiles

>>

Beisijie Height Adjustable Table Black Lifting Gaming Table Electric Desk

>>

A2-70 Stainless Steel Machine Screw Hex Hexagon Grub Socket Set Screw Socket Hex Pan Flat Head Phillips Countersunk Machine Screw Tapping Driling

>>

Contemporary Leaf-Inspired Crystal Chandelier with Clustered Design

>>

5-Port Industrial-Grade DIN-Rail Ethernet Router with Nat

>>

Grinding Mill Price Stone Mill Grind Machine Limestone Powder Making Machine Raymond Mill with Dryer for Diabase Powder

>>

Greetmed High quality hospital adjustable electric bed

>>

Water Proof Disposable Plastic Pp Cpe Medical Boot Shoe Covers Disposable Non Slip

>>

Windproof Sunshade Slats Aluminum Shutter Window

>>

fiberglass plastic grating panels Industrial frp grating

>>

17 for FOMOS Autoclave door gasket sterlization door seal replacement seal o- ring Chamber seal accessories and tools

>>

Corken 691 Reciprocating Oil-Less Lubrication LPG Gas Booster Compressor

>>

High Quality Paper Product Making Machinery Auto Pasting Machine

>>

Laboratory High Quality Electro-thermostatic Blast Oven Up to 300 Degrees

>>

High Output Nine Corner Pallet Making Machine Plastic Pallet Tray Blow Molding Machine

>>

7.75" Non-Stick Coating Stainless Steel Scuba Diving Knife Dive Knife

>>

Neodymium 200 Watt Generator Permanent Magnet N52

>>

Filter element 304 316 Stainless steel perforated filter tube

>>

CH-12p Series Fast Wire Connection Fast Quick Connector Terminal Blocks