|

US$11,000.00-25,000.00

|

1 Set

(MOQ)

|

Basic Info.

Material Processed

Plastic Flakes

Computerized

Computerized

Certification

ISO9001:2008, CE

Application

Recycling Extrusion Pelletizing

Function

Make Recycle Plastic Granules

Machinery Test Report

Provided

Core Components

Bearing, Gearbox, Motor

Transport Package

Film Packing

Packaging & Delivery

Package Size

3000.00cm * 1500.00cm * 1500.00cm

Package Gross Weight

1500.000kg

Product Description

State-of-the-Art Plastic Recycling Washing Line: Engineered by Wenzhou Wandun Machinery Co., Ltd., this PE Plastic Recycling Machine with Enhanced Washing Line is meticulously crafted to deliver unparalleled efficiency in the granulating process. Immerse yourself in a world of superior performance and unwavering reliability, meticulously tailored to meet and exceed your plastic recycling needs.

Product Description

The plastic recycling washing system is a cornerstone of Kitech machinery's recycling series. This ingeniously designed, modular system is tailored to handle rigid plastics and bottles. It efficiently processes various types of plastics such as PE, LDPE, HDPE, PC, PS, and ABS, ensuring optimal soft recycling.

Kitech offers customizable module combinations designed to meet your specific requirements and material conditions. With the capability to handle a wide range of raw materials, Kitech provides production lines ranging from 300 to 10,000 Kg. Choose from economy to high-level configurations to match your production needs.

Introduction:

| Type | WT500 | WT100 | WT2000 | WT3000 |

| Capacity(kg/h) | 400-500 | 800-1000 | 1600-2000 | 2500-300 |

| Dimension(L*W*H) | 35*10*5 | 50*12*6 | 70*12*6 | 120*20*6 |

| Steam consumption(kg/h) | 0-150 | 0-200 | 0-300 | 0-600 |

| Chemical consumption(kg/h) | 0-3 | 0-5 | 0-10 | 0-20 |

| Energy consumption(kwh) | 175 | 198 | 306 | 550 |

| instalation power(kwh) | 210 | 330 | 498 | 810 |

| *** (person /shift) | 3-5 | 3-8 | 3-10 | 3-12 |

Main Technical Variables:

Belt conveyor:

Heavy-duty type, equipped with a gear motor;

Side walls designed to prevent material spillage;

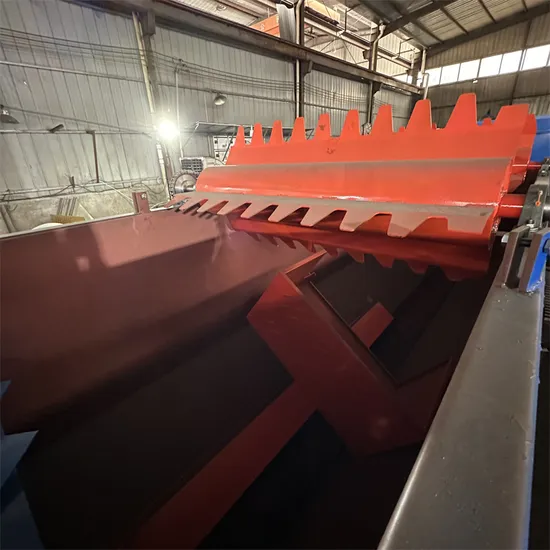

Crusher:

Precisely engineered, the blades are sharp and powerful;

Enclosed cutting chamber to contain materials;

Externally adjustable knives for ease of use;

Shredder:

Specially designed hopper to prevent material ejection;

Four-way rotating knives with unique holders;

Extremely robust pedestal bearing housings;

External mounting of bearing pedestal designs;

Screw conveyor:

Constructed with wear-resistant stainless steel screws;

Triple sealing with external bearing design;

Washing tank:

Double station discharge valve positioned at the bottom;

Variable speed control via inverter;

Heavy-duty washing unit, enabling separation of materials with different densities;

Friction washer:

Rotor and blades made from wear-resistant steel;

Rotor with dynamic balance treatment, achieving an accuracy of ±3-5g;

Active material washing to safeguard downstream units;

Centrifugal dryer:

Rotor with dynamic balance treatment, ensuring an accuracy of ±3-5g;

Mild circular screen designed in a four-piece polygon configuration;

The washer/dryer housing is constructed with stainless steel welded construction;

Squeezing dryer:

Heavy-duty shaft and blade;

Double hydraulic press units;

Motorized screw squeezing;

Hot air pipe dryer:

Pipeline constructed with stainless steel welding;

All material-contacting parts are stainless steel;

Hot air drying system for efficient drying;

Storage buffer:

Directly connected with the pelletizing process;

Large storage capacity for uninterrupted operation;

Electrical cabinet

Equipped with international brand low voltage components;

Double circuit safety relay for enhanced protection;

Intelligent and modular PLC controlling system for seamless operation.

Q1. What are your terms of packing?

A: Our standard packaging includes placing the machine on a protective pallet and securely wrapping it with plastic film to ensure safe transportation.

For exports to European countries, we meticulously ensure that our wooden boxes are thoroughly fumigated, guaranteeing safe and compliant transport. Our dedicated packing process includes the use of PE film, and we proudly offer customized packing solutions tailored to meet the unique requirements of our esteemed customers.

We are fully equipped and prepared to accommodate special requests, ensuring that we meet your specific needs and preferences with meticulous attention to detail.

Q2. What are your payment terms?

A: Our payment terms are straightforward and transparent: we require a 30% deposit via T/T, with the remaining 70% due before delivery. To ensure complete transparency, we provide detailed photos of the products and their packaging before the final payment is made.

Q3. What are your delivery terms?

A: We offer a range of flexible delivery terms including EXW, FOB, CFR, and CIF, designed to accommodate your specific logistical needs.

Q4. What is your delivery timeframe?

A: Generally, our delivery timeframe ranges from 30 to 60 days following receipt of your advance payment. The exact timeframe may vary depending on the specific items and quantities in your order.

Delivery times are flexible and may vary based on the intricate details and specifications of your order.

Q5. Do you test all your products before delivery?

A: Absolutely, we conduct a comprehensive 100% test on all our products to ensure they meet our rigorous high-quality standards before delivery.

Q6: How do you ensure long-term and positive business relationships?

A: 1. We consistently deliver high-quality products at competitive prices, providing maximum value to our customers.

2. We treat every customer with the utmost respect, building genuine and lasting business relationships and friendships, regardless of their background or origin.

>>

Hotel Used Coffee Pot Water Jug Can Be Put in The Dishwasher Double Wall Stainless Steel 304 Tea Pot Vacuum Flask

>>

Chinese Hot Sale 3 5 Gallon PC Barrel Blowing Moulding Machine with Servo Motor

>>

For Wholesale Auto Brake System Clutch Pressure Plate 41300-23138 4130023138 41300 23138 Fit For Hyundai For KIA Korean Car

>>

Roll Label to Sheet Cutting Machine

>>

Hot sale!!! portable goat milking machine for sale/ vacuum milking machine

>>

Solar USB Charger Bag Foldable Mobile Phone Battery Pack Power Bank Factory Original

>>

2014 2019 GLA250 GLA W156 Rear Bumper Lower Diffuser Trim 1568852600

>>

Super Quality Automatic Fish Feeding Machine Fish Feed Maker Machine Medium Fish Feed Machine Complete Fish Feed Machines

>>

ASTM A234 WPB Fitting

>>

Best Selling EU Standard Fly Metal Laser Printer Auto Parts Laser Marking Engraving Machine for Metal

>>

Acmtch Hot Sale PVC Foam Board Making Machine WPC Sheet Production Line PVC Foam Board Making Machine

>>

Pnmd-B Series Wood Rotary Cutter Sharpener Knife Grinder Venner Peeling Machine Blades Sharpening Machine Electric Knife Grinding Machine

>>

Bulk Order Cheap Price Natural Flavor Dehydrated Potato Flakes for Export

>>

Modern Height Home Office Table Standing Electric Desk

>>

Wholesale Men′s Cotton High Quality Custom Logo Slim Fit Knitted Pullover Long Sleeves Sweaters

>>

Pulp Banneton,9 10 Inch Baking & Pastry Tools Kitchen Sets Oval Bread Proofing Basket Baneton Proofing Basket Banneton Bread Set

>>

Casting Aluminum High Pressure Centrifugal Water Pump Impeller

>>

Press Brake Top Quality with Competitive Price

>>

CNC Drilling and Milling Machine Desktop Drilling and Milling Machine

>>

13 Gauge HPPE Knitted 5 Level PU Coated Anti Cut Glove