Basic Info.

Function

Put Pressure on The Plywood

Low Pressure Pump Motor Power

22 Kw, 2 Pieces

Total Motor Power

64.7 Kw

Transport Package

Plastic Film / Plywood

Specification

4220*2020*11300 mm

Production Capacity

3 Sets / Month

Product Description

Detailed Photos

Product Parameters

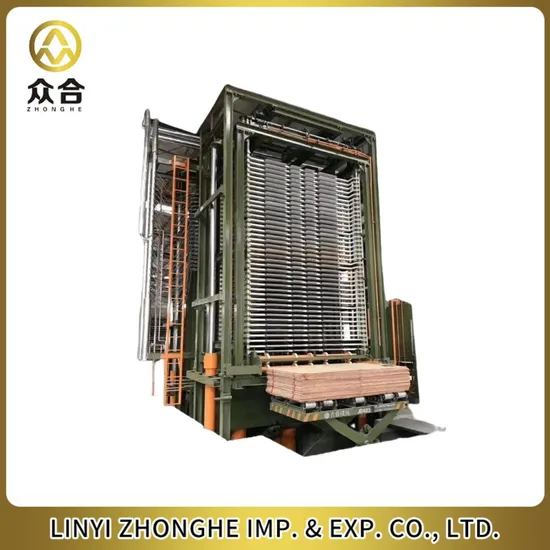

PRODUCT PARAMETER

| FULL AUTOMATIC 36 PLATES 800 TONS HOT PRESS PRODUCTION LINE |

| PART 01: FULL AUTOMATIC LOADING SYSTEM TECHNICAL SPECIFICATIONS |

| 1 | Standard unit size | 1220*2440 mm, 1 complete unit |

| 2 | Opening size | 80 mm |

| 3 | Opening number | 35 |

| 4 | Lifting pistons | diameter 140 mm, stroke 4450 mm, 2 pieces |

| 5 | Working stroke | 4450 mm |

| 6 | Lifting speed | 18 meters per minute |

| 7 | Main frame size | 4220*2020*11300 mm |

| 8 | In feeding motor power | two hydraulic motors |

| 9 | In feeding roller conveyor | 1 unit |

| 10 | In feeding roller conveyor motor | 0.75 KW |

| 11 | In feeding Lift table and automatic sucker | 1 unit |

| 12 | Weight | 14.5 tons |

| PART 02 : 36 PRESS PLATES 800 TONS HOT PRESS MAIN TECHNICAL PARAMETERS |

| 1 | Norminal pressure | 800 Tons (8000 KN ) |

| 2 | Hot press plate size | 2700*1370*42 mm, material Manganese steel Q355 |

| 3 | Hot press plate steam input style | double inlet, double outlet |

| 4 | Unit part size | 1220*2440 mm, 1 unit |

| 5 | Opening size | 80 mm |

| 6 | Opening number | 35 |

| 7 | Big pistons | diameter 320 mm, stroke 2950 mm, 4 pieces |

| 8 | Small pistons | diameter 180 mm, stroke 2950 mm, 2 pieces |

| 9 | Working stroke | 2800 mm |

| 10 | Unit working pressure | 21 kg/cm² |

| 11 | No-load closingtime | 300 mm/s |

| 12 | Machine size | 3580*1370*7400 mm |

| 13 | Hydraulic oil tank size | 2550*1250*1800 mm |

| 14 | Hydraulic oil tank volume | 3 cubic meters |

| 15 | Hydraulic oil tank weight | 2000 kg |

| 16 | Low pressure pump motor power | 22 KW, 2 pieces |

| 17 | High pressure pump motor power | 11 KW, 1 piece |

| 18 | Plywood In put and out put oil pump motor | 7.5 KW, 1 piece |

| 19 | Lifting motor power | 2.2 KW, 1 piece |

| 20 | Total motor power | 64.7 KW |

| 21 | Workshop height | 7500 mm |

| 22 | Foundation depth | 5050 mm |

| 23 | Total weight | 73 Tons |

| PART 03: FULL AUTOMATIC UNLOADING SYSTEM TECHNICIAN SPECIFICATIONS |

| 1 | Standard part size | 1220*2440 mm, 1 complete set |

| 2 | Opening size | 80 mm |

| 3 | Opening number | 30 |

| 4 | Lifting pistons | diameter 140 mm, stroke 4950 mm, 2 pieces |

| 5 | Working stroke | 4950 mm |

| 6 | Lifting speed | 18 meters per minute |

| 7 | Machine size | 4200*2020*11300 mm |

| 8 | Output driving power | hydraulic motor |

| 9 | Output lift table | 1 unit |

| 10 | Automatic plywood STACKER | 1 unit |

| 11 | Out put roller conveyor motor power | 0.75 KW |

| 12 | Weight | 14.5 tons |

| PART 04: Frame type Automatic Stacker Specifications |

| 1 | plywood size | 1220*2440 mm |

| 2 | stacking height | 1200 mm |

| 3 | Stacking power | gear reducer |

| 4 | Motor power | 0.75 KW |

| 5 | Stacking speed | 2 seconds per sheet |

| 6 | Machine size | 3050*3200*2080 mm |

| 7 | Out put lift table | 1 unit |

Company Profile

Linyi Zhonghe Machinery Company is professional in solutions of wood veneer production machine, plywood production machine, particle board machine, MDF board machine, saw mill machine, wood veneer, plywood, other related material and parts for wood processing industry, construction material and machine, etc.The detail business range is as following:1-wood veneer production machine:Log cutting machine, log debarker, core veneer peeling machine, face veneer peeling machine, wood veneer dryer, wood veneer clipper, wood veneer stacker, veneer tape, etc.2-plywood production machine, film faced plywood machine:Core veneer composer, putty spreader, veneer sanding machine, veneer jointer, glue powder, glue making machine, glue mixer, glue spreader, base plywood forming machine, cold press, hot press, bolier, Double Dimension saw, sanding machine, wood dust collector, stainless steel plates, cushion pads, etc.3- Particle board machine and MDF board machine.4-Saw mill machine: Vertical band saw, horizontal band saw, saw blade sharpener.

Certifications

Packaging & Shipping

FAQ

FAQ

1. Rich experience and professional design

We have abundant experience in plywood production, also has many years exporting experience. Each equipment location,passage will be designed reasonably to meet safety production.

2. Competitive price

ZHONGHE has own factory,with the same configuration,the price is competitive.And we are familiar with the Chinese market,our suppliers provide high-quality cost-effective accessories.

3. Timely after-sale service

We have over 15 skilled technicians offer after-sale service, will be sent to the customer's factory to assist in the installation and debugging of the flooring production line until it runs well,and asked for quick responses to customer questions.

4. One-stop solution

ZHONGHE provideS one-stop service, including market analysis and professional technical consultation, raw materials ,equipment installation, personnel training.Professional after-salesservice team,renovation of old equipment,make turnkey projects.

5. Quality control

Strict quality control of equipment in production and before leaving the factory, and a complete quality management system for purchased parts.Customers are always welcome to make videos or come to the factory to know the production status.

>>

Most Popular Compact Excavator Free Shipping Mini Excavator Chinese Crawler Digger Earth Moving Machine Mini Excavator Small Digger

>>

China Manufacturer Supply Building Material Anti-Static Access Floor HPL Panel for Computer Room, Data Center

>>

Non-Slip Glazed Ceramic Indoorrustic Tile Bathroom Ideas for Wall Decoration

>>

Truck Loading Motorized Expanded Flexible Roller Conveyor Manufacturer Joinsun China UL CE

>>

Chengming Crafts Factory Wholesale Industrial Bookcases Bookshelf Home Office Furniture Corner Wooden Book Shelf Rack for Living Room

>>

Gaide Top Supplier Breshless Cordless Chainsaw with Two Battery

>>

High Quality Carbon Steel Chain Pipe Wrench

>>

Automatic Pick and Place Machine Carton Packing Machine Bottle Packer

>>

Transparent Glass Double Glow Wake-Up Led Light Digital Alarm Clock Radio Sunrise Wake Up Light Lamp

>>

Factory Price Two Person New Arrival Fishing Inflatable Kayak Drop Stitch Canoe

>>

Delphi Lucas CAV Fuel Injection Pump Rotor Head 7185-044L

>>

Customizable 13m Aluminum Fire Rescue Boat with Monitor Fire Pump Cabin Cruiser Type

>>

FUDA Small Volume Automatic 1 Filling Port Stretch Down Pants Stuffing Machine with 2 Weighing Scale

>>

IS200SRTDH2ACB IS200STAIH2A GE Voltage input module PLC industrial control system

>>

M-TECH STYLE BODY KIT FOR BMW X5 F15 SERIES

>>

Factoryshop Best Cut Proof Hppe Glass Fiber Liner Smooth Nitrile Leather Coated Anti Cut Resistant Levels 5 Work Safety Kitchen A5 Gloves with En388

>>

Popular Wood Acrylic CO2 Laser Engraving Machine and Laser-Engraving-Machine

>>

OEM 21008573 Auto Engine Part Timing Gear for Saturn 1.9L TG1367

>>

Designed for Low Energy Losses Efficient Oil Type Transformer

>>

Water/Soft Drink/Juice Combi Pet Bottle Rinsing Filling Capping Machine