Product Details

Product Description

Product Description

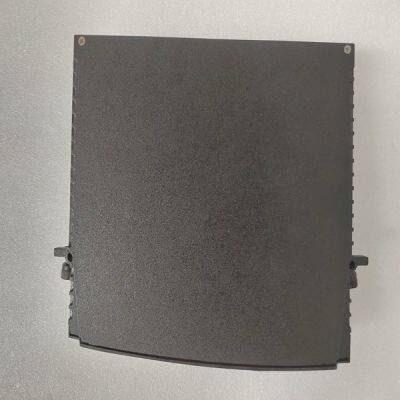

Brand:TRICONEX

Type:TCM 4355X

Origin: the United States

Warranty: 365 days

Colour: new/used

Shipping method: Courier delivery

Module of PLC, DCS, ESD system card, the card is a vibration monitoring system, steam turbine control system module, the advantages of the gas generator spare parts brand: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts of our products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, mechanical, electronic manufacturing, automobile manufacturing, plastic machinery, electric power, water conservancy, water treatment/environmental protection, boiler heating, energy, power transmission and distribution and so on.

This step will be the first time the drive is enabled and the motor will have current in it. Make sure that the motor current loop gain parameter KIP in the drive is set to 2*pi*2000*(motor L line-line in Henry) and NV saved by using S200 Tools. The drive, SynqNet master will be set to output fixed current vectors independent of actual motor position and the motor will be moved in small increments like a stepper motor. Set the MEI filter gains to zero. In S200 Tools, set the drive to "stepper motor mode" (no commutation) by setting DPoles = 0. Set the S200 parameter CommOff to 0. Command a positive current in the coil via MoCon by setting a low but nonzero positive and negative current limit (say, +2500 counts each). The rms current in the motor will be this value times the drive Ipeak divided by the scaling number 19336 counts. For example, in an S20660 18 Arms peak drive 2500 corresponds to 18*2500/19336 = 2.3 Arms. Make sure the current selected is low enough not to overheat the motor coils but high enough to get the motor to move. Enable the drive and the motor should move to a magnetic pole alignment position.

That is, the motor will swing to its pole position, oscillate around that position, and stop. Note the encoder position. Now command a small (try 10) positive CommOff. The resulting motion should be in the positive encoder direction. That is the encoder counts should have increased. If there is enough friction in the system you may need to adjust the current higher, just make sure the current is within the motor coil rating. You can also try going further by setting CommOff to higher angles up to 180 degrees. If the resulting motion was in the negative encoder direction, you will need to swap any pair of motor power leads. The setup now has the motor coils, the Hall commutation sensor, and the encoder all agreeing on the same positive direction. Disable the drive. Set Commutation Offset Angle: Zero the current command in the MEI MoCon utility as done in the Positive #3 step. Restore DPoles to its proper non-zero value. For linear motors this is usually 2 and for rotary motors must be the actual number of magnetic poles per revolution. For linear motors make sure AuxFBDivsor is set correctly to get commutation to work. See Chapter 8 Advanced Configuration for help with these NV parameters. Enable the drive while holding the motor. There should be 0 current command and there should be no force yet. Now apply a small (for example +1000 counts) current command in the MEI MoCon utility as described above. The motor should show a uniform force that doesn't vary as a function of magnetic cycle. Don't worry about the force direction. Now, try setting CommOff in S200 Tools to -120, 0, +120. Two of these settings will produce force in the wrong (negative) direction at one-half the expected force level. Use the value that produces positive direction force with the higher force level. NOTE: The above last step assumes that the motor was built conventionally and the Hall Commutation logic edges mechanically lined up with the motor line-line back EMF zero crossings. If the Hall commutation sensor has random alignment then you may need to make more careful measures to set CommOff to the optimal value which will give you the most force per amp of drive current.

>>

Fully Automatic Extrusion Smal Plastic Pet Bottle Blow Molding Machine

>>

Liuzhou wuling LJ4A15Q petrol engine auto car parts

>>

Plant Use 1-2t/H Biomass Wood Pellet Complete Production Line Price for Sale

>>

China Precision Key Type Inflatable Air Expanding Shaft Manufacturer Price 12inch Pneumatic Board Type Air Shaft for Unwinder

>>

Wholesale Velvet Necklace Pendant Gift Box Jewelry Gift Box

>>

Custom Logo Bamboo Branded Gold Wood Shape Blank Custom Opener with Handle Logo Wooden Beer Keychain Bottle Opener

>>

Fein Titanium Bi-Metal Oscillating Saw Blade

>>

Mining trommel screening plant compost trommel multi screen for sale

>>

FRP/GRP High-Strength Chemical Drinking Water Winding Process Fiberglass Pipe, Large-Diameter FRP Pipe

>>

Customized large gear ring dryer flywheel gear ring refining equipment non-standard large gear ring

>>

Full Zirconia Bridge Design MYY Dental Lab - Outsourcing China Dental Lab

>>

Yichen Rechargeable Two-Purpose LED Headlamp Detachable for Bicycle Light Head Light

>>

Sunshing High Quality Nano SIM Card Adapter Contact Smart IC Card

>>

High Quality Modified Ford Ranger Body kit 2016 truck body parts

>>

BS3799 / ASTM A733 Seamless Steel Pipe Nipple Screwd On End A312 TP304 / 304L

>>

Excavator Attachment 3cbm OEM Rock Standard Bucket Skeleton Excavator Bucket

>>

High Quality Chinese TBR/PCR/OTR/Truck Tire/Tyre for Radial/Bus 825r16 825r20 900r20 1000r20 11r22.5 12r22.5 295/80r22.5 315/80r22.5 385/65r22.5 1100r20

>>

tool carrying soft bag & case

>>

300L Dairy Cosmetic Vacuum High Pressure Emulsifier Homogenizer Price

>>

Factory Supplying 9rt Series 9460rt 9470rt 9510rt 9520rt 9560rt 9570rt Agricultural Friction Type Rubber Track