|

US$8,500.00-9,500.00

|

1 Set

(MOQ)

|

Basic Info.

Speed of Welding

40-60times/Min

Welding Width

914-2100mm(According to Your Requirements)

Wire Feeding

Line Wire From Coil Automatically

Transport Package

Wooden Pallet, Plastic Package in Container

Specification

3100X1700X1400mm

Production Capacity

50 Sets/ Month

Product Description

Product Description

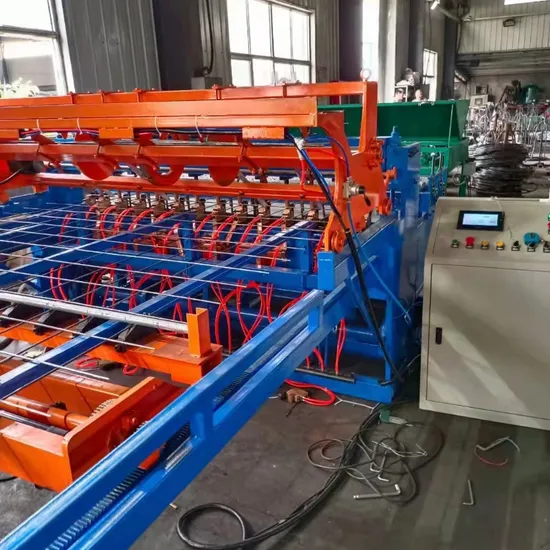

Welded wire mesh machine, also called, welded roll mesh machine, electric welded mesh machine. Our roll welding wire mesh machine is featured by wire coil feeding and invert speed control.It is used to make wall mesh,construction mesh,animal cage, mining etc.

Electric control cabinet

Panasonic (Japan) PLC

Weinview (Taiwan) touch screen

ABB (Switzerland Sweden) switch

Delta (Taiwan) power supply

Panasonic (Japan) servo driver

Phoenix (Germany) wire terminal

Specially designed relay board

Automatic wire feeding way

The longitude wires will be through first straight setting roller device. The wire storage device can feed the longitude wires step by step, then through second straight setting roller device.

Automatic welding system

1. Upper copper arm connect two welding electrodes, much easier for electric conduction. (European design)

2. The upper arm and lower electrode base are water cooling type. Welding electrode: 25*25*30mm.

3. The electro-magnetism valves are all SMC brand, originally imported from Japan, good quality.

4. Copper plate connect lower electrode base and welding transformers, much easier for electric conduction.

5. One welding electrode is controlled by one SMC brand air cylinders, big power, high welding speed.

6. Cast water-cooling welding transformers, high efficiency. Welding degree is adjusted by PLC.

7. Separate control technology, one electric board and one SCR controls one welding transformer.

8. The circuit board is designed by our engineers and university professors, not be easily broken.

9. The SCR is Infineon (Germany) brand, very good quality.

Automatic mesh pulling system

1.Panasonic (Japan) servo motor&planetary reducer for pulling mesh, more precise.

2.The cross wire space can be set and adjusted on the touch screen.

3.Cable drag chain is European design, very good quality, not easily hung down.

4.Pulling rack is J&T brand, made in Taiwan, the pulling distance is more accurate, less noise.

Automatic mesh pulling system

High precision type. The cutting length can be set by PLC.

After mesh cutting, the max.6m mesh can fall down and move out automatically.

Product Parameters

| Item | SE-2000A | SE-2500A | SE-3000A | SE-3300A |

| Number of Electrodes | 20 | 24 | 30 | 32 |

| Max.Mesh Width | 2500mm | 2500mm | 3000mm | 3300mm |

| Wire Diameter | 5.0-12.0mm | 5.0-12.0mm | 5.0-12.0mm | 5.0-12.0mm |

| Mesh Length | 3-12m | 3-12m | 3-12m | 3-12m |

| Cross Wire Space | 100-300mm | 100-300mm | 100-300mm | 100-300mm |

| Line Wire Space | 100-300mm | 100-300mm | 100-300mm | 100-300mm |

| Electric Capacity | 200KVA*10 | 200KVA*12 | 200KVA*15 | 200KVA*16 |

| Welding Speed | 40-60t/min | 40-60t/min | 40-60t/min | 40-60t/min |

| Control System | PLC control and Touch Screen |

Finished Product

Features at a Glance

The advantage of this welded mesh making machine is that the machine does not need to stop while roll mesh system unloading the wire mesh. This method greatly improves the production efficiency of the wire mesh and increases the competitiveness of the products.

After sale service:

1.Engineer can install, test and adjust the machine for you

2.24 hours online after-sale service

3.We will train workers for you

Packaging & Shipping

1.1*40GP container for loading one set machine with roll forming machine.

2. Main machine body and decoiler is load naked (tighten to container with steel wire rope)

3. Spare parts and operating tools are loading in tooling box.

Company Profile

We, Tangshan Shuoen is a professional cold roll forming machine manufacturer, We have been focusing on this field for 10 years. Our equipment includes roof roll forming machine, floor deck roll forming machine, automatic decoiler, light keel roll forming machine, purlin machine, leveling and slitting machine, and other related construction equipment.Shuoen has employed a team of engineers for more than 10 years. At the same time, our machines use branded electrical components, raw materials from branded steel factories, strict process control, two-year warranty, installation and training services.Our customers are all over the world, such as 65 countries in Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, South Africa, Kenya and other different regions. We have extensive experience in the needs of different countries, such as profile, thickness range, use, installation, etc.Thank you for your trust and choice, we will provide you with the best service support and help you achieve greater success.Looking forward to more cooperation with new and old friends from all over the world.

Certifications

FAQ

Q1. How long is your warranty period?

Within 12 months from the date of self loading, we guarantee that no malfunctions will occur due to manufacturing defects.

Q2. How can I trust the machine to paste and test before shipment?

We have recorded a test video for your reference. Alternatively we welcome you to visit our factory and personally test the machines.

Q3: If you can customized the roofing sheet forming machine for i need?

Yes, Just share your design to us is ok, we will give you one fully quotations.

Q4: What's your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers' workshop if needed.

Q5: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time.

>>

Ut Machinery Single Shaft Shredder Scrap Metal Shredder for Recycling Plasitc Film

>>

Aluminum Alloy Chain Lift Platform Hydraulic Lifts for Disabled People Wheelchair Lifts

>>

Comfortable And Resistant To Scratching Lovely Dinosaur Sofa Cat Scratch Board Large Space Cat Scratching Board

>>

2L 5L 10L 20L Short Path Distillation with Vacuum Short Path Molecular

>>

Bsdf Industrial Chilli Spice Lentils Garlic Peas Red Pepper Powder Processing Plant Spices Chili Pepper Ginger Grinding Machine

>>

Good Performance Water-Cooled Pulverizer Automatic Pulverizer for Pharma and Food

>>

100% Cotton Newborn Baby Hats

>>

Yn27c Air Rock Drill Multi-Purpose Gas Driven Drilling Machine Tool for Coal

>>

Uhmw-Pe Timing Chain Adjuster Chain Tensioner

>>

High Cost Performance Full Auto CNC Knife Paper Pleating Machine Plcz55-1050-a

>>

Silicone button of POS machine

>>

#5 Brass Close End Auto Lock Green Tape for Amy Zipper

>>

HC-B013 Intelligent Uroflowmeter with competitive price / urine flow meter/ urine measurement

>>

Willing OL145 Wholesale small thermal laminator machine A4 A5 A6 Thermal Laminator Machine

>>

75 Inch LCD Touch Screen 4K HD Interactive Flat Panel 55 65 75 85 86 98 100 110 Inch Android OPS Smart Board Interactive Board for Classroom School

>>

High-Performance Layflat Hose Making Machine for Efficient Manufacturing

>>

Best Plastic Japanese Portable Black Rechargeable Private Label Electric Heated Eyelashes Curler

>>

Top 10 Logistics Company DDP Door to Door Sea Shipping From China to USA Professional Sea Freight Forwarder USA Fba 20days

>>

Zero waste pla nonwoven fabric 2023 hot sale biodegradable polylactic acid pla nonwoven fabric applications

>>

OE#26694693A Front Bumper Lower Guard for Chevrolet Buick 2001-2022