|

US$6,000.00-85,000.00

|

1 Set

(MOQ)

|

Basic Info.

Automatic Grade

Automatic

Pallet Size

1280*900*25/40mm

Molding Cycle

15-20 Seconds/Time

Execution Capability

Jc/T2094-2001

Transport Package

Container

Specification

5400*2250*2740mm

Origin

Langfang Hebei China

Production Capacity

4104million Bricks/Year

Packaging & Delivery

Package Size

1150.00cm * 212.00cm * 210.00cm

Package Gross Weight

18000.000kg

Product Description

Product Description

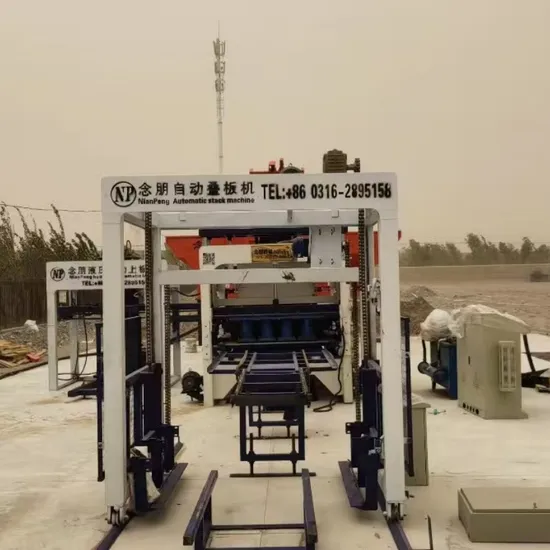

NP QT12-15A Multi-Purpose automatic brick-making machine

This machine is very popular type automatic hollow block making machinery, can make different size hollow block, solid bricks, pavers, hourdis,S blocks and so on.

We accept your customized block mould size, also can supply you brick samples for your reference.All of machines are give you factory directly competitive price.

Detailed Photos

EQUIPMENT FEATURES

Excitation system is the core part, according to the principle of mechanicalresonance centrifugal force, the introduction of German technology to achieve full synchronization, full isolation, directional vibration pressure, with large vibration force, rapid start, smooth operation and other characteristics, in the leading level in China; The hydraulic control system adopts imported high-frequency proportional valve, which can automatically adjust the flow rate in the production process, protect the cylinder, so that the cylinder forward and backward ends have a buffering effect, thus improving the stability, extending the service life of the cylinder, and improving the speed and flexibility of the action of various parts; Through the security logic control, the fault diagnosis, text alarm and other prompt functions are added to the program control, when there is miss-operation, the fault can be accurately diagnosed; The machine is simple to operate, with high efficiency, energy saving, economic,

practical and other characteristics.

| Bricks Description | Bricks/Mould

| Output(10 HRS)/BRICKS

|

| Paving brick 200×100×(60/80)mm

| 35 | 63000 Bricks

|

| Solid brick 240×115×53mm | 57 | 136800 Bricks

|

| Porous brick 240×115×90mm

| 27 | 64800 Bricks

|

| Hollow brick 390×190×190mm | 12 | 24000 Bricks |

Advantages:

• Environmental protection and energy saving: fly ash, coal gangue, slag, smelting slag and other industrial waste residues can be used as the main raw materials to reduce the exploitation of natural resources, reduce energy consumption, realize waste recycling, meet environmental protection requirements, and promote sustainable development.

• Low cost: Raw materials such as industrial waste residues are relatively easy to obtain and low in price, which can effectively reduce production costs; at the same time, the equipment has low energy consumption and low overall production investment. The block products produced have certain price advantages in the market and large profit margins.

• High production efficiency: The equipment has a short molding cycle and can produce blocks quickly and continuously, which can meet the needs of large-scale production, increase unit time output, and bring higher economic benefits to the enterprise.

• Good product quality: Through reasonable vibration, pressurization and other processes, the blocks have high density, high strength, high dimensional accuracy, stable and reliable product quality, which can meet the strict requirements of construction projects for block quality and ensure the safety and durability of buildings.

• Easy operation: Equipped with advanced control systems such as PLC control and human-machine interface, the operation is simple and easy to understand, and no professional technicians are required to operate, which reduces the labor cost and training cost of the enterprise.

•One machine for multiple uses: You only need to replace the mold to produce hollow blocks, porous bricks, standard bricks, curbstones, pavement bricks and grass bricks and other blocks of various specifications and shapes to meet the needs of different construction projects, increasing the applicability and economy of the equipment.

•Long service life: The machine body is made of high-precision, high-strength castings and special welding processes and materials. It has good rigidity and strong seismic resistance, can withstand long-term high-intensity work, has a long service life, and reduces the equipment renewal cost of the enterprise. Product Parameters

about Us

>>

Suitable Body Fat Caliper For Measuring or Analyzer With BMI Measuring Body Tape for Body - Skin Fold Measuring By Dental point

>>

Best Price Used for Konica Minolta Bizhub Copier C1070 C2070 Digital Machine

>>

High Speed and Cost Performance CNC Mini Milling and Drilling Machine

>>

Energy Saving Used Plastic Recycling Machine Pet Washing Line

>>

New Arrival 3 Tiers Bamboo Storage Basket With Handle Handmade natural gift basket & boxes Wholesale Made in Vietnam

>>

New Smart Beverage Wooden Case Servo High Speed Paper Cup Machine

>>

Top Sell Cattle Lifting Frame, Auxiliary Cows Get up Veterinary Equipment

>>

Running Badger 2.0 High Performance Adult Electric Go Kart with Affordable Cost

>>

Electronical ABS/PP Precision Shell/ Cap/Cover Parts Plastic Injection Molding Mould

>>

Pressure Homogenizer High Quality Homogenizer Juice Homogenizer

>>

Rigid Modular Interlocking Garage Floor Tiles Industrial Design Easy Car Wash

>>

201 thickened stainless steel floor drain specification 200mm anti-corrosion and durable

>>

Diesel Wood Grinder Chipper Shredder Sawdust Powder Crusher Making Machine for Sale

>>

Fermented Fishmeal Processing Machine with SUS304 Steel

>>

Manual Large Conventional (CNC) Double Dual Column Vertical Lathe C52 Series C5231C522510T Loading

>>

DIN933 DIN931 OEM Fasteners Ss201 SS304 SS316 Stainless Steel Hex Bolt

>>

Heat Transfer Paper Neck Label Printing Paper Size Label Printing Paper

>>

Fully Automatic Banana Slice Potato Chips French Fries Production Line

>>

protective punch plastic blister trays black perforate blister packaging

>>

Cup Cake One to five automatic mold release Packaging line