Basic Info.

Computerized

Computerized

Certification

CE, ISO9001:2008

After-sales Service

Installation to The Customer′s Country

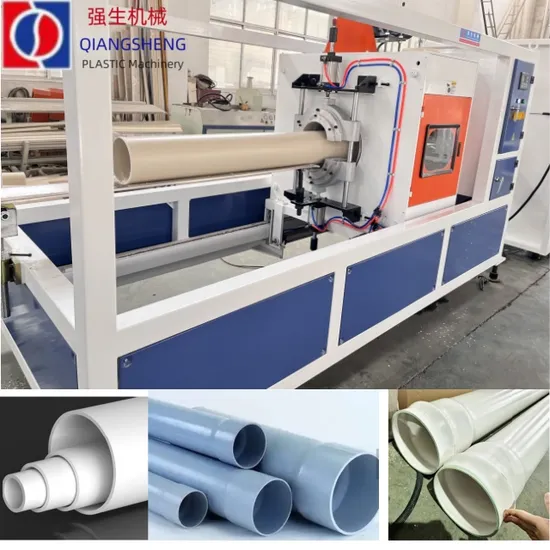

Name

PVC Pipe Making Machine

Temperature Control

Omron Brand

Max.Output(Kg/H)

1000 Kg/H

Screw Speed (Rpm)

120 Rpm

Core Components

Motor, Pump, PLC, Pressure Vessel, Gearbox, Screw

Machinery Test Report

Provided

Control

Siemens PLC+Touch Screen

Showroom Location

Egypt, Turkey, Italy, Viet Nam, Saudi Arabia

Transport Package

PE Film Winding Wrapping

Specification

25000*1200*1800MM

Origin

Zhangjiagang, China

Production Capacity

20PC/Month

Packaging & Delivery

Package Size

2400.00cm * 230.00cm * 230.00cm

Package Gross Weight

5000.000kg

Product Description

PVC PIPE EXTRUSION LINE

Φ20-Φ630 series PVC pipe extrusion line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing,cable laying etc.

This line is composed of conical twin screw extruder,Vacuum calibration tank,haul off,motors,cutter and stacker etc. The extruder and haul off methods are two-claw,three-claw four-claw,six-claw,eight-claw,ten-claw,twelve claw etc.

You may choose saw blade cutting type or planetary cutting type. It is aditionaly attached with length counter and intensifying device.

Model

| Pipe diameter

(mm)

| Extruder

| Max output (kg/h)

| Max speed

| Total power

(kw)

| Line length

(m)

|

PVC-50x2

| 16-50

| SJSZ51/105

| 150

| 6m

| 60

| 20

|

PVC-63

| 16-63

| SJSZ51/90

| 120

| 10m

| 45

| 20

|

PVC-110

| 50-110

| SJSZ51/105

| 150

| 6m

| 60

| 24

|

PVC-160

| 75-160

| SJSZ65/132

| 300

| 5m

| 100

| 24

|

PVC-250

| 110-250

| SJSZ80/156

| 400

| 3.5m

| 120

| 28

|

PVC-315

| 125-315

| SJSZ80/156 | 400

| 3m

| 160

| 28

|

PVC-450

| 250-450

| SJSZ92/188 | 700

| 1.5m

| 200

| 36

|

PVC-630

| 315-630

| SJSZ92/188 | 700

| 0.9m

| 230

| 36

|

Main Features of PVC Pipe Machine: We have different models of PVC pipe making machine for making different PVC pipe diameter, the pipe can be used as electrical conduit pipe, water supply pipe, water drainage pipe,well water pipe....the following machine model for your reference

1. It is mainly used to produce all kinds of UPVC pipes for agricultural water supply and drainage, building water supply and drainage and cable laying, etc.2. Saw cutter and planetary cutter for choice.3. Changing some parts can also produce M-PVC pipe, C-PVC pipe, inner spiral wall pipe, inner hollow wall pipe, formed core pipe.4. Coincal twin screw extruder and parallel twin screw extruder for choice5. Double-strand for four-strand for choice for small pipes

Advantages:

It can process various soft and rigid PVC, especially process powder directly into pipe shape. It consists conical twin-screw extruder, vacuum calibration tank, haul-off unit, stacker or belling machine, etc.

The screw extruder and haul-off unit adopt AC inverters. All electric parts are international well-known brand products, which guarantee quality of machine. The PLC and big true-color screen panel make control system with high automation.

Flow chart of PE pipe extrusion line

Material →Heating Cooling Mixer →Material Feeding →Conical Twin Screw Extruder →Extrusion Mould & calibrator → vacuum CalibrationCooling Tank → (Spray Cooling Tank) →Printer → Haul-off Unit →cutter →stacker

Double Screw Extruder.

1.1 Simens Motor

1.2 Frequency Inverter:ABB Brand

1.3 Temperature Controller:Omron Brand

1.2 Spiral Structure of Barrel

1.3 Special Design of Screw

1.4 Air Cooled Ceramic Heater

1.5 High Quality Gearbox

Extrusion Die Head.

2.1 Moving Device of Die Head

2.2 Die Head Rotary Device

2.3 Heat Exhausting Device

2.4 Cooling Device for Core

Extrusion die head apply spiral structure, each material flow channel is placed evenly. Each channel is after heat treatment and mirror polishing to ensure material flow smoothly. Die head structure is compact and also provide stable pressure, always from 19 to 20Mpa. Under this pressure, pipe quality is good and very little effect on the output capacity. Can produce single layer or multi-layer pipe.

Vacuum Tank.

3.1 Strong Cooling for Calibrator

3.2 Better Support for Pipe

3.3 Silencer

3.4 Pressure Relief Valve

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. We use double-chamber structure. First chamber is

in short length, to ensure very strong cooling and vacuum function. As calibrator is placed in the front of first chamber and pipe shape is formed mainly by calibrator, this design can ensure quick and better forming and cooling of pipe.

Haul off unit.

5.1 Pipe Clamping Device

5.2 Water Tank Filter

5.3 Quality Spray Nozzle

5.4 Pipe Support Adjusting Device

5.5 Pipe Support Device

Haul off unit provides sufficient traction force to pull pipe stably. According to different pipe sizes and thickness, our company will customize traction speed, number of claws, effective traction length. To ensure match pipe extrusion speed and forming speed, also avoid deformation of pipe during traction.

Planetary cutting machine.

6.1 Universal Clamping Device

6.2 Central Height Adjustment

6.3 Saw and Blade Interchangeable

Cutter controlled by Siemens PLC, working together with haul off unit to have precise cutting. Customer can set the length of pipe,they want to cut.

Multi-feed-in actions for the accomplishment of one cutting process (protect blades and saws, prevent from blade

and saws stuck for thick pipe and cut face of pipe is smooth).

Belling Machine.

-Single or Double heating oven.-The belling machine is widely used in all kinds of plastic pipes.

-The function is to facilitate the connection between pipes.

-It could be used in pipe production line Or separately.

-U type and R type expansion of plastic pipe.

| The company's main products(Click Text) |

| PVC Pipe Extrusion Line | PVC Fiber Pipe/Hose Extrusion Line | PE Two-layers Pipe Extrusion Line |

PE Pipe Extrusion Line(Large Diameter)

| PE Corrugated Pipe Production Line | PVC Foam Board Production Line |

3-Layers PPR Pipe Production Line

| PVC Plastic Windows Machine

PVC Ceiling Production Line

PVC Window Shutter Machine

PVC Rain Gutter Machine

PVC Corner Production Line

PVC Great Wall Panel Machine

PVC Cable Trunking Machine | PP PE Two-stages Pelletizing Line

PP PE One-stage Pelletizing Line

PVC Hot-cutting Pelletizing Line

PP PE Water Ring Pelleting Line |

Zhangjiagang City Qiangsheng Plastic Machinery Co.,Ltd.

Zhangjiagang City Qiangsheng Plastic Machinery Co.,Ltd.is located in Jingfeng town Sanxing Industry park, Zhangjiagang City.Our factory has 31 years of history, the machine quality and after-sales service are guaranteed.

Its main products:double-screw extruder, single-screw extruder, sets of extruding production lines and auxiliary equipment, such as, PE, PP, PVC, PP-R plastic pipe production line,plastic profile production line, plastic granutating line, plastic recycling line and others.

Descriptionct Description

Q1:What about the payment terms?

A1:Always 30% down payment as deposit,70% balance pay before shipping.

Q2:What about the payment way?

A2:TT,L/C at sight or Made in China trade assurance.

Q3:If you will send engineer coming to our factory to install and test the machines?

A3:Yes,Every set of machine we will send professional engineer to your factory and help installation and test the machines for you.

Q4:If you have CE,SGS,ISO certificate?

A4:Yes,except these,if you also need other certificates,we also can help to apply.

Q5:If we buy your machines, can you offer us wear-out spare pats?

A5:Yes,We provide our high quality machine 1 years' guarantee,and we will also offer you 1 years wear-out spare parts for free. Once your machines broken or doesn't work within 1 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tools. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Q6:What is the voltage?

A6 380V 50hz 3 phase or any other voltage according to client's requirement.

>>

Laundry Soap Detergent Production Line Mixing Tank

>>

FUJI Escalator Recidential Escalator Commercial Escalator

>>

8.5mm/8mm/7.5mm/6.5mm Unilin Click Lock Spc PVC Flooring Covering Vinyl Floor Planks

>>

Outdoor Kitchen BBQ Grill Cabinets Islands Heavy Duty 304 Stainless Steel

>>

Hydraulic Bottle Jack with Safety Valve Tool CE Certificated Car Lift 12 Ton

>>

Manufacturer: Calcium silicate insulation board, insulation board, high-temperature resistant tube shell

>>

NPK Double Horizontal Shaft Compulsory Conctere Mixer Construction Machinery Small Szie Blender Australia

>>

Cfmoto 800cc 1000cc ATV 4X4 Cforce UTV Quad Zforce Efi EPS

>>

Wear-Resistant Custom Logo Nylon Jacquard Elastic Strap Tape for Hats

>>

LANYING heavy mesh woven loom machine

>>

33*33CM Silicone Kitchen Sink Protector Mat for Stainless Steel Sink Porcelain Bowl & Delicate Dinnerware

>>

Reduced Glare 100W 150W 200W 240W Warehouse Linear LED High Bay Light

>>

E6000 Multi-gas Detector to Detect Combustible and Toxic Gas

>>

PET plastic capsule 175cc clear bottle

>>

HAM MUTTON SAUSAGE BACON SLICERS CHINA SLICING KNIFE SERRATED salmone flutes edge CHINO CUCHILLO JAMONERO

>>

Pex Al Pex Pipe Pex Al PE Aluminium Plastic Composite Pipe PE Al PE Water Gas Pipe

>>

Processing Custom Shredder Blade Sharp Wear-Resistant Source Manufacturers Matching Double-Shaft Shredder Blade

>>

Deluxe Vibrating Relax Calf Leg Massager Foot Massage Machine

>>

LINGKE store recommended 20kHz 2600W digital type stable plastic ultrasonic welding machine

>>

Hotel Lobby Copper Wall Sconces Lamp with Resin in White Color